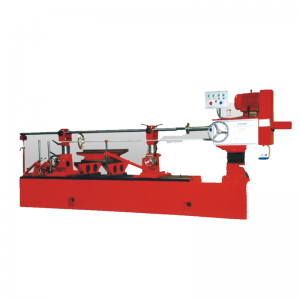

Precision CNC boring umshini

UKUBUKEZWA KONKE

I-1, Lo mshini uklanyelwe amapayipi adonswa abandayo noma amapayipi ashisayo ashisayo, anesicefe, akhuhla futhi agingqe ukuze kucutshungulwe ama-diameter angaphakathi ukuze kuzuzwe usayizi wokunemba okuhle nokuqedwa kwendawo enhle.Amapayipi adonswa ngamakhaza angu-27 SiMn, 30CrMnSi, 42CrMn.Amapayipi agqinqiwe ashisayo angacishwa futhi afutheke noma cha,ipayipi lensimbi elidonsa ngokubanda liyisimo esidonswa ngokubanda (liqinile) noma isimo sokudambisa ingcindezi.

2, Imisebenzi

2,1 Ukulungiswa kwamapayipi okukhethekile kuthatha amapayipi ephenduka ngesikhathi sokuzungezisa amakhanda ayisicefe ekucubunguleni okuyisicefe, ukuze kusetshenziswe imishini enzima eqonde emigodini.

2.2 Ukulungiswa kwamapayipi okukhethekile kuthatha ukuphenduka kwamapayipi, ibha yokunweba eyisicefe hlala unganyakazi, amathuluzi okugingqa ayisidina we-hydraulic enza ukucubungula okuhle ukuze athole ukunemba okuhle, aqonde nokunye.

2.3 Amapayipi akhethekile agcina amapayipi anganyakazi, Ibha eyisicefe iyazungeza, ukusebenzisa amathuluzi okuginqika ayisicefe ukugingqa amapayipi ukuze aqedele kahle.

ABALINGISI

Izici eziyinhloko zomshini oyisicefe we-CNC ukucubungula kahle kakhulu, ukusebenza okuzinzile, uhlelo lokusebenza lwe-CNC oluhlakaniphile nolulula, ukubukeka okuhle, ukubukeka okuhlangene nokuhlelekile, nezindlela ezingcono zokuvikela imvelo ngokumelene nokuchaphazwa kukawoyela nokuvuza.

Imishini inezenzo ezintathu ezilandelayo ezihlanganisiwe ze-workpiece nethuluzi: 1), i-workpiece nethuluzi lizungeza ngesikhathi esisodwa.2) I-workpiece ilungisiwe futhi ithuluzi liyajikeleza.3) I-workpiece ijikeleziswa futhi ithuluzi lilungisiwe.Ikhanda eliqinile eliyisicefe lisetshenziselwa ukuphusha okuyisicefe emishinini enzima, futhi inqubo yokuhlanganisa ithuluzi yokuklwebha + rolling (i-hydraulic noma i-pneumatic) isetshenziswa ekuqedeni, okuxazulula ngempumelelo ukuchezuka okungathi sína emishinini enzima yamapayipi ensimbi agingqike ashisayo nokujula. izimbobo zamapayipi ensimbi adonswa ngokubanda.Isimo sokungaqondi kahle kahle ngemva kokuqeda.

Ngemuva kokuklwebula nokuginqika ngokushesha, ukunemba kungafinyelela izinga le-IT7-8, ukuhwaqana kwendawo kungafinyelela ku-Ra0.1-0.2μm, nge

ithuluzi lomshini elifakwe ithuluzi elizenzakalelayo lokunwetshwa kanye nemojuli yokulawula ukufinyela, ithuluzi elizinikele lesitayela sase-Korea se-pneumatic & German-style hydraulic tool kanye nesistimu yokuhlehlisa ukuze uthole ukuqedwa okuhle.Isibonelelo esiphezulu sokukrwela nokuginqika singu-0.5-10mm ohlangothini lobubanzi).

Amathuluzi omshini wochungechunge lwe-TGK afakwe uhlelo lokulawula izinombolo lwesiJalimane lwe-SIEMENS 808D;ibhokisi lokuphotha elijikelezayo lokusebenza lishayelwa yi-spindle servo motor enokulawulwa kwejubane elingenasinyathelo, ibhokisi lokuphotha eliyisicefe lishayelwa yi-spindle servo motor enokulawulwa kwesivinini esingenasinyathelo, kanti i-spindle bear yamukela ukunemba okuphezulu ngokunemba okuphezulu kokujikeleza.Ibhokisi lokuphakelayo lishayelwa yi-AC servo motor enomthethonqubo wejubane ongenasinyathelo;umzimba wombhede wenziwe ngensimbi ephonsiwe yekhwalithi ephezulu, futhi ama-rails omhlahlandlela we-flat-flat aqinisekisa ukuqina okuphelele nokuhleleka okuhle kwethuluzi lomshini, futhi kunezakhiwo zokuzivikela ezizungezile.Ithuluzi lomshini lifakwe isidluliseli se-chip esizenzakalelayo, isihlukanisi kazibuthe, isihlungi sephepha, njll., ukuze kuqinisekiswe ngokugcwele ukutholakala okuhlanzekile nokusetshenziswa kabusha kwesipholile, futhi ukunemba kokuhlunga kungafinyelela ku-30 μm.

IMIPHAKATHI YOBUCHWEPHESHE

| NO | Izinto | Amapharamitha |

| 1 | Ibanga lobude obuyisicefe | 2000-1200mm noma ngokwezifiso |

| 2 | Ububanzi be-clamping ye-roll | 40-350mm noma ngokwezifiso |

| 3 | Ububanzi be-clamping bezinto zamandandatho | 50-330mm noma ngokwezifiso |

| 4 | Ububanzi bezinsimbi zomhlahlandlela | 650 mm |

| 5 | Ukuphakama kwesikhungo se-spindle | 400 mm |

| 6 | I-Headstock motor | 75KW, nikeza injini |

| 7 | Isivinini sokujikeleza kwe-Headstock | 90-500r/min |

| 8 | I-Headstock spindle dia | ≥280mm |

| 9 | Imoto yamathuluzi ayisicefe | 55KW, nikeza injini |

| 10 | isivinini sokujikeleza samathuluzi ayisicefe | 100~1000r/min, ukulungiswa okungenasinyathelo |

| 11 | Injini yokudla | 27nm |

| 12 | Isivinini sokudla | 5-3000mm/min, ukulungiswa okungenasinyathelo |

| 13 | Isivinini sokunyakaza kwe-apron | 3000mm/min |

| 14 | Isistimu yokulawula | SIEMENS 808D |

| 15 | I-Hydraulic pump motor | N=1.5kW,n=1440r/min |

| 16 | Injini yephampu yokupholisa | N=5.5kW, amasethi ama-3 |

| 17 | Ingcindezi elinganiselwe yokupholisa | 0.5MPa |

| 18 | Ukugeleza kwesistimu yokupholisa | 340 L/min |

| 19 | Ubukhulu | 14000mm*3500mm*1700mm |

| 20 | Ukunikezwa kwamandla kagesi | 380V, 50HZ, 3 isigaba |

| 21 | Indawo yokusebenzela | Izinga lokushisa lendawo yokusebenza: 0 - 45 ℃Umswakama ohlobene: ≤85% |

INCAZELO YEZIMALI EZIBALULEKILE

1, Ukwakheka komshini

Umbhede wamukela isakhiwo sesitimela esiyisicaba esingunxande esiphindwe kabili, kanti ububanzi besitimela esiwumhlahlandlela bungama-650mm.Umbhede uyingxenye eyisisekelo yethuluzi lomshini, futhi ukuqina kwawo kuthinta ngokuqondile ukusebenza kokusebenza kanye nokunemba kokusebenza kwalo lonke ithuluzi lomshini.Umbhede womshini wenziwe ngesihlabathi se-resin, uphonswe ngensimbi yekhwalithi ephezulu engu-HT300, ukwelashwa kokuguga, ngokubukeka okuhle namandla, ukwakheka kwepuleti lezimbambo ezinengqondo, izimbambo eziqinisayo ezimise okwe-Π zenza umbhede ube nokuqina okuhle kakhulu, ukumelana nokudlidliza nokumelana nesigaba. ukuhlanekezela..Uhlangothi lwangaphandle lombhede luphonswa nge-reflow tank, futhi isembozo sokuzivikela sifakwe nxazonke, esinokusebenza okuhle kokuvikela ukubukeka futhi akukho ukuvuza kwamafutha.Ingakwazi ukuqoqa kahle uketshezi lokusika futhi igxilise ukugeleza okubuyela emuva kancane ukuze iphinde isetshenziswe.Umbhede wamukela uhlaka oluhlukanisayo lokuhlanganisa, isitimela esiqondisayo sithatha ukucisha imvamisa emaphakathi, isendlalelo sokucisha singu-3-5mm, nokuqina kobuso yi-HRC45-52.Igayidi yesitimela esiqondisayo iwumhlaba oqondile, okwenza ithuluzi lomshini libe nokungagugi okuhle nokugcinwa okunembayo.Isakhiwo sokuhlukanisa i-splicing sinengqondo futhi asibangeli ukuvuza kwamafutha.

2, I-Headstock (izimbobo ezinkulu, ukususwa kwe-chip emgodini ongaphakathi wokuphotha)

I-headpiece ejikelezayo ye-workpiece ikakhulukazi ishayela i-workpiece ukuze ijikeleze futhi igxilwe ekugcineni kwesokunxele sethuluzi lomshini.I-drive motor ye-workpiece ejikelezayo ye-headstock isebenzisa i-servo spindle motor.Ibanga lejubane liyi-90-500r/min.I-headstock yamukela ukwakheka kwe- through-spindle.Ingxenye yangaphambili ye-shaft eyinhloko ifakwe nge-conical disc, futhi ukuphela kwangemuva kwe-shaft eyinhloko kufakwe ipayipi yokukhipha i-chip.Ngesikhathi somshini, amafutha okusika ahlanganiswe nezinsimbi zensimbi futhi akhishwe ngembobo yangaphakathi ye-shaft eyinhloko ekuphumeni okuzenzakalelayo.ngaphakathi emshinini we-chip.Isakhiwo sonke silula, ukuqina kwe-shaft eyinhloko kuyathuthukiswa, futhi ukugcinwa okunembayo kuhle, okuqeda umcimbi wokugijima nokudonsa.

3,Ibhokisi lebha eliyisicefe liyisakhiwo sokusakaza esibalulekile futhi lifakwe kuphalethi lokuphakelayo.Ibhokisi le-bar eyisicefe lishayelwa yi-main shaft servo motor, futhi i-shaft eyinhloko iqhutshwa ukuze ijikeleze ngebhande elihambisanayo ngokusebenzisa indlela yokushintsha isivinini.Ukukhethwa kwejubane kunganqunywa ngokuya ngezinto zokusebenza, ubulukhuni, ithuluzi kanye nezimo zokuphulwa kwe-chip nezinye izici.Ngokuya ngesivinini esihlukile, ingahlelwa futhi isethwe uhlelo lokulawula izinombolo, futhi ama-spindle bearings akhethwa kuma-bearings e-Wafangdian.Umsebenzi oyinhloko webhokisi lebha eliyisicefe ukushayela ithuluzi ukuze lijikeleze.

4,I-oil dispenser itholakala phakathi nombhede.Ingxenye engaphambili yesikhipha uwoyela ifakwe umkhono othwala uwoyela ojikelezayo, osetshenziselwa ukufaka umkhono womhlahlandlela oyisicefe, futhi umkhono womhlahlandlela ungazungeza kanye nomsebenzi.Uhlangothi olungemuva lwesikhiqizo sikawoyela luhlinzekwa ngembobo yokufaka uketshezi olusikiwe, ijoyinti lokuthela kanye nepayipi, futhi uketshezi olusikayo lujovelwa embotsheni engaphakathi yesiqeshana sokusebenza ngomgodi osebhokisini lesikhipha amafutha.

Kunenani elikhulu loketshezi lokusika olunomfutho ophezulu ebhokisini lesiphakeli sikawoyela phakathi nenqubo yomshini.I-workpiece ijovwe ku-workpiece ngohlangothi lwe-feeder kawoyela.Umkhono womhlahlandlela wethuluzi lokuphakela uwoyela ulawula ukunemba kokulinganisa kwethuluzi kanye nendawo yokusebenza ngaphambi nangemuva kokuphakelwa.Ingemuva elingemuva lomkhono wokusekela ibha eyisicefe yizingxenye Ezishintshekayo zesigaba sezinsiza zamathuluzi omshini.I-shaft eyinhloko ye-feeder kawoyela kanye ne-shaft eyinhloko yethuluzi lomshini inokugxila okuphezulu kanye nokunemba okuhle kokujikeleza.

Ukuhamba kanye nokugqekeza kwe-dispenser kawoyela kushayelwa i-frequency conversion motor ukushayela umshini wegiya ukuze ujikeleze, futhi ukunyakaza kanye nemisebenzi ye-jacking ye-dispenser kawoyela itholwa ngokuhlangana kwe-gear shaft kanye negiya le-helical.Ukuze uthole okukhiphayo kwe-torque okungaguquki, usayizi wamandla okuqinisa angaphezulu uyalungiseka.I-cone disc ingafakwa ekugcineni kwe-oil dispenser, esetshenziselwa ukuqinisa i-workpiece.

5,Ubakaki wesikhungo sebha eyisicefe utholakala phakathi kwesiphakeli samafutha kanye nebhokisi lebha eliyisicefe.Isetshenziselwa ukusekelwa okuyisizayo kwebha eyisicefe.Isekela ngokuyinhloko ibha eyisicefe futhi ilawula isiqondiso esihambayo sebha eyisicefe.Ibha ekhethekile eyisicefe ifakwa ngembobo yangaphakathi yebakaki eyisicefe.Ikhithi yokusekela (eyethuluzi lensiza yethuluzi lomshini) idlala indima yokumunca ukudlidliza kwebha eyisicefe, futhi umkhono wosekelo wangaphakathi unomsebenzi wokuzungeza.Umkhono wokusekela ojikelezayo phakathi kwebhakhethi yebha eyisicefe uhlanganiswe nebha eyisicefe, ekulungele ukushintshwa ndawonye lapho ibha eyisicefe ishintshwa.

6, Uhlelo lokudla

Iphalethi lokuphakelayo lithatha isakhiwo sesihlalo sesihlalo sephalethi, esithuthukisa ngempumelelo ukuqina kwesihlalo sehhashi, futhi sisekela ujantshi oqondisayo nge-span yama-650mm.Isihlalo sehhashi nepuleti lama-slide kuphonswe ngesihlabathi se-resin futhi kwelashwa ukuguga okuzenzela.Indawo ngayinye yesitimela engumhlahlandlela iyindawo ebalulekile yokucubungula.

Iphalethi lokuphakelayo lithatha i-rack kanye ne-pinion structure, igiya liqhutshwa yi-servo motor, futhi inqola iqhutshwa yi-meshing nge-rack, ukuze ibone ukuphakela nokuhamba ngokushesha kwenqola.Lonke uhlelo lokuphakelayo lunezici zokunemba okuphezulu, ukuqina okuhle, ukunyakaza okushelelayo nokugcina ukunemba okuhle.Amanye amaphutha ekucubunguleni ithuluzi lomshini angaphendulwa iyunithi yokunciphisa ithoshi futhi ayeke ukusebenza ngesikhathi ukuze kuvikelwe ukuphepha kwamathuluzi omshini, amathuluzi nezinto zokusebenza ngaphakathi kwebanga elithile.

I-7, ukususwa kwe-chip, ukupholisa uketshezi lokusika, ukuhlunga, ukugcinwa kanye nokunikezwa, uhlelo oluphelele lweyunithi yepompo yepompo kawoyela:

Lonke uhlelo lwamukela ukwakheka kwethangi likawoyela elingaphezulu komhlaba.Idivayisi yokususa i-chip: umshini wokukhipha i-chip othomathikhi wohlobo lwepuleti → isihlukanisi esizibuthe → iphampu ejikelezayo → isihlungi sephepha esinomfutho ophezulu → isihlungi sokuhlukanisa sedimentation sezigaba eziningi → iphampu kawoyela eyinhloko.

Uhlelo lokupholisa: Ngamaqembu amathathu amaphampu egiya, lunikezwa kumshini wokukhipha uwoyela, futhi amazinga okugeleza ahlukene angatholakala (amaqembu ama-3 wamaphampu 300L/min, 600L/min, 900L/min) ukuhlangabezana nezidingo ezahlukene ze-workpiece. usayizi wokuvula.

Isistimu yokuhlunga ejikelezayo iyithangi lamafutha elihlukile elinamasethi amabili amaphampu kawoyela ajikelezayo afakiwe.Iphampu kawoyela ejikelezayo ixhunywe ohlelweni lokuhlunga ethangini likawoyela eliyinhloko, ukuze amafutha ethangini likawoyela eliyinhloko ahlanzeke ngokuqhathaniswa.Isihlungi esizungezayo ngaphezu kwethangi lamafutha elikhulu kufanele sihlanzwe noma sishintshwe njalo.

8, Imikhiqizo

Ifakwe amasethi angu-2 wabakaki V-block, amasethi angu-2 abakaki berola, namasethi angu-2 esikhungo esinezimotho ezinenjini, asetshenziselwa ukusekela ucezu lokusebenza.Isikulufu sokuhola sesandla, i-nut lift, ingalungiswa ngokuzenzakalelayo ngokuya ngobubanzi bezinto zokusebenza ezihlukene.Idlala ngokuyinhloko indima yokuthwala nokulungisa isikhundla se-workpiece eyisicefe.

9, iHydraulic system

Yamukela izingxenye zasekhaya nezangaphandle ezithuthukile ze-hydraulic ukuze uqinisekise ukusebenza okuzinzile nokuthembekile.Lawula ukunwetshwa nokufinyezwa kwethuluzi.Ingcindezi nesivinini kuyalungiseka.

10, Uhlelo lokulawula ugesi

Iqukethe iKhabhinethi yokulawula ugesi, idivayisi ye-AC servo drive, isistimu yokulawula ugesi, isiteshi sokulawula, njll. Izingxenye zikagesi ezine-voltage ephansi zisebenzisa i-Schneider brand, izixhumi zezindiza, futhi ukuhlelwa kwamandla anamandla futhi abuthakathaka kuyafaneleka.Uhlelo lokulawula izinombolo lwe-Siemens lusetshenziselwa ukulawula zonke izingxenye zomshini wonke, futhi isikrini se-LCD sibonisa izenzo neziyalezo ezihlukahlukene zethuluzi lomshini.(Naka ubude nesikhundla sesiteshi sokulawula, futhi usibeke endaweni okulula ukusebenza futhi okungelula ukushaywa ngayo; iphaneli yokulawula yakhelwe ukuvimbela ukungena kukawoyela, futhi uwoyela akufanele ungethwe izinkinobho namaphaneli ukuze kunwetshwe impilo yesevisi yesistimu).

11, Iphaneli yokulawula

Ithuluzi lomshini lisebenza kakhulu kumshini wokukhipha uwoyela, futhi iphaneli yokusebenza yesistimu yokulawula izinombolo igxilile enqoleni yokukhipha uwoyela.I-headstock kanye nebhokisi lebha eliyisicefe nakho kufakwe ukusebenza okuhambisanayo nezinkinobho zokumisa izimo eziphuthumayo, ezilungele ukulawula ithuluzi lomshini.Iphaneli yamukela iphaneli ye-aluminium alloy, ukwakheka okuphelele kuyavumelana, kuhle futhi kuhlala isikhathi eside.

12, Ukuvikelwa

Isembozo esiyisivikelo se-peripheral sifakwa ngaphandle kombhede, futhi imiphumela yokuvikela imi kanje: (1) Ukusebenza kahle kokuvikela ukubukeka, akukho ukuvuza kwamafutha, kungaqoqa ngokuphumelelayo uketshezi lokusika, futhi lubuyisele ndawonye ukuze lusetshenziswe ngokuphindaphindiwe.(2) Ukubukeka kulula futhi kuhle.