Abasiki bezintambo yinsimbi, i-CBN (i-cubic boron nitride), i-Ceramic, idayimane nokunye.

Izinhlobo zamathuluzi okusika i-lathe:

Ngokuya ngesicelo, amathuluzi okusika i-lathe ahlukaniswe ngokuyisisekelo abe izinhlobo ezimbili:

A) Ngokuhambisana nendlela ithuluzi elisetshenziswa ngayo.

B) Indlela yokuphakela ngokwesicelo

A) Kuya ngokuthi ithuluzi lisetshenziswa kanjani:

Kunezinhlobo ezingu-11 zommese:

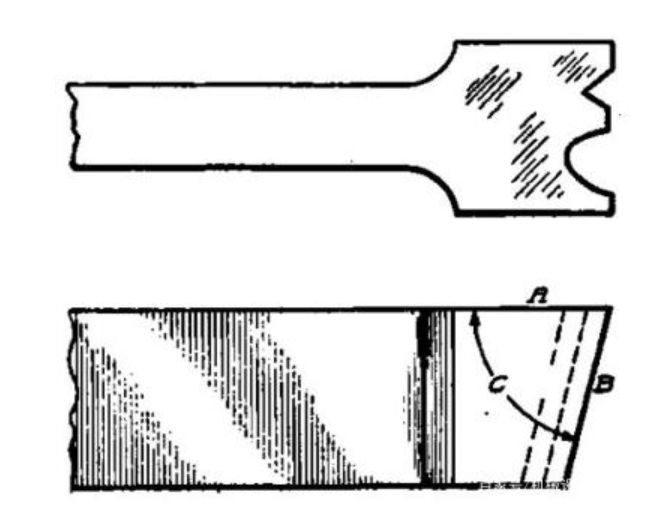

1. Amathuluzi okusika intambo

Ziyizinhlobo ezimbili:

Amathuluzi Afakwe Intambo Yangaphandle - Amathuluzi anentambo yangaphandle ayaziwa nangokuthi amathuluzi okuthunga.Achazwa njengamathuluzi okwenza imicu yangaphandle yama-workpieces.

Ithuluzi lentambo yangaphakathi—Ithuluzi lentambo yangaphakathi lichazwa njengethuluzi elisetshenziselwa umshini wochungechunge lwangaphakathi kucezu lokusebenza.

2. Ithuluzi le-Chamfering

Ithuluzi le-chamfering lingachazwa njengethuluzi elisetshenziselwa ukuklama ama-bevel noma ama-grooves kuma-bolt.Lawa mathuluzi asetshenziselwa ukuphazamisa amakhona ama-workpieces.Lapho inani elikhulu le-chamfering lidingeka, ithuluzi elithile lokugezela elinama-side chamfers liyadingeka.

3. Amathuluzi okuguqula

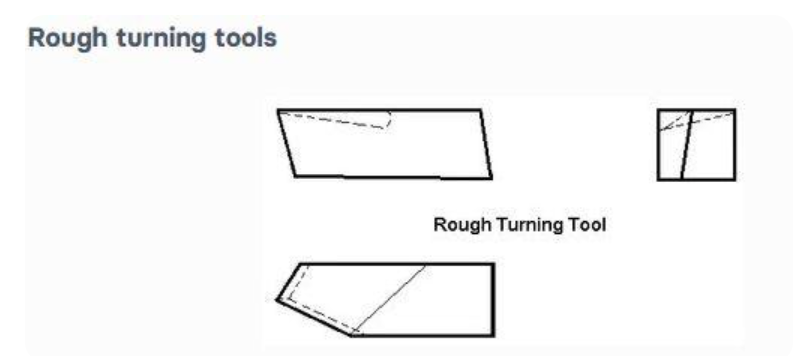

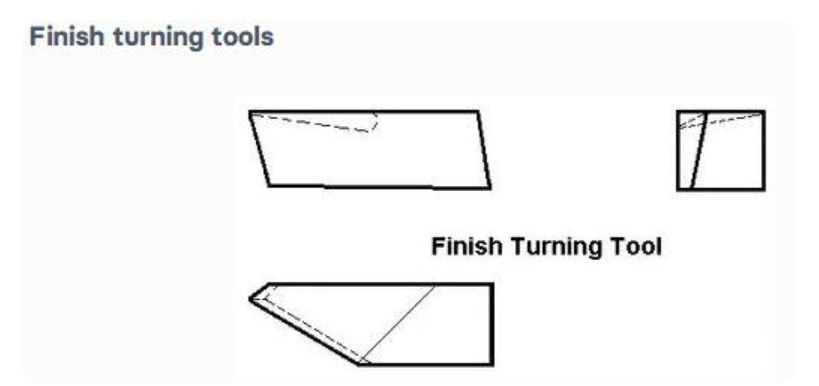

Ngokuvamile kunezinhlobo ezimbili zamathuluzi okuguqula:

Amathuluzi Okuguqula Amathuluzi - Amathuluzi okuguqula ama-rough asetshenziselwa ukususa inani elikhulu lensimbi ngesikhathi esifushane kakhulu.Futhi i-angle yokusika icacile futhi ingakwazi ukumelana namandla amakhulu okusika.

Imimese Ejika Kahle - Amathuluzi okuguqula kahle asetshenziselwa ukususa amanani amancane ensimbi.I-engeli yokusika nayo iphansi ukuze ikhiqize indawo ebushelelezi futhi enembile

4. Slotting ithuluzi

Amathuluzi okugaya ngokuyisisekelo achazwa njengamathuluzi asetshenziselwa ukudala imbobo ewumngcingo yokujula okuthile kukhoni, isilinda noma ngaphezulu kwengxenye.Kulokhu, ukwakheka okuqondile kwethuluzi le-grooving kufanele kukhethwe ngokuya ngokuthi ama-grooves okusika onqenqemeni ayisikwele, ayindilinga, njll.

5. Qeda umsiki wobuso

Ithuluzi lobuso lingachazwa njengethuluzi elisetshenziselwa ukusika indiza e-perpendicular ku-axis of rotation of the workpiece.Ithuluzi lobuso liphathwa isibambi samathuluzi esigxiliswe kusiphathi somshini.Isetshenziselwa ukunciphisa ubude be-workpiece ngokunikeza i-perpendicular ku-axis ye-lathe.Umkhawulo wokusika wethuluzi kufanele usethwe ekuphakameni okufanayo nendawo ephakathi kwendawo yokusebenza.

6. Ithuluzi eliyisicefe

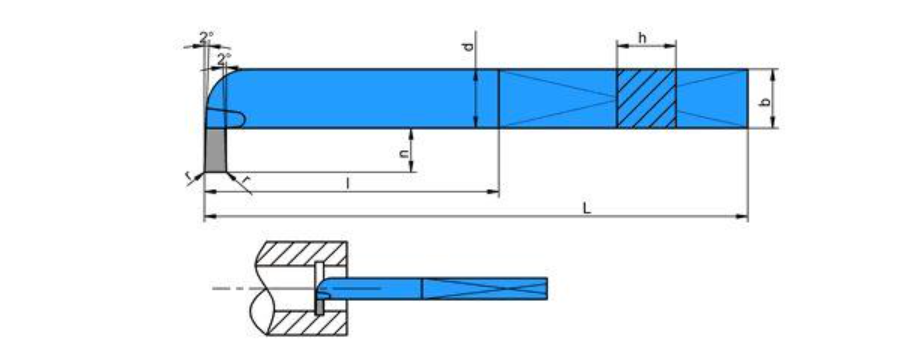

I-Boring iyithuluzi le-lathe elisetshenziselwa ukukhulisa izimbobo.Uma ufuna ukukhulisa imbobo ekhona, udinga ukusebenzisa ibha eyisicefe.Imigoqo ebhokayo ingabhobhozwa kalula emigodini evele ibhoboziwe futhi yandiswe ngobubanzi.Ingashintshwa ngokushesha kusayizi ukuze kufakwe kahle ezinye izingxenye.

7. Ithuluzi lokwakha

Amathuluzi okwakha angachazwa njengamathuluzi asetshenziselwa ukwakha izinhlobo ezahlukene zamajamo wokusebenza.Kulokhu, uhlobo olukhethekile lwekhava noma umnikazi lusetshenziselwa ukubamba ithuluzi lokwakha.Kusukela kulokhu senza izinhlobo ezahlukene zokusebenza, njengokwenza irediyasi yangaphakathi, irediyasi yangaphandle, njll.

8. Counter ithuluzi boring

Ithuluzi eliyisicefe elingemuva lingachazwa njengethuluzi elisetshenziselwa ukukhulisa nokuthola inhloko yesokhethi yesikulufu noma ibhawudi.Leli thuluzi linama-radii amabili:

A) Dala izimbobo esezimbiwe

B) Geza izimbobo endaweni yokusebenza

9. Ithuluzi lokubuyisela kabusha

Ithuluzi lokubuyisela kabusha lichazwa njengethuluzi elisetshenziselwa ukuqeda kanye nokubekezelela ubukhulu bezimbobo ezibhoboziwe noma ezibhoboziwe.

10. Ithuluzi lokusika

Amathuluzi wokusika ayafana namathuluzi okugaya.Kulokhu, ithuluzi elingaphansi lisetshenziselwa ukubhoboza izimbobo ezinkulu ebangeni elingaguquki ukusuka ekugcineni komgodi.I-undercutting ngokuyinhloko yenziwa emculweni wangaphakathi ukuze kususwe.

11. Amathuluzi okubhoboza

Amathuluzi okubhoboza nawo angamathuluzi abaluleke kakhulu kuma-lathes.Amathuluzi okumba asetshenziswa kakhulu umshini izimbobo cylindrical ku workpiece enikeziwe.Kulesi simo, i-workpiece igxiliwe kuphaneli, i-drill bit igxiliwe kuhlaka lokugaya i-tailstock, futhi umgodi kufanele ugcwaliswe ngokuhamba kwe-spindle ye-tailstock.Lokhu kusebenza kuma-workpieces anomumo ovamile.

B) Ngokwendlela yokuphakela isicelo:

Ahlukaniswe abe izinhlobo ezintathu:

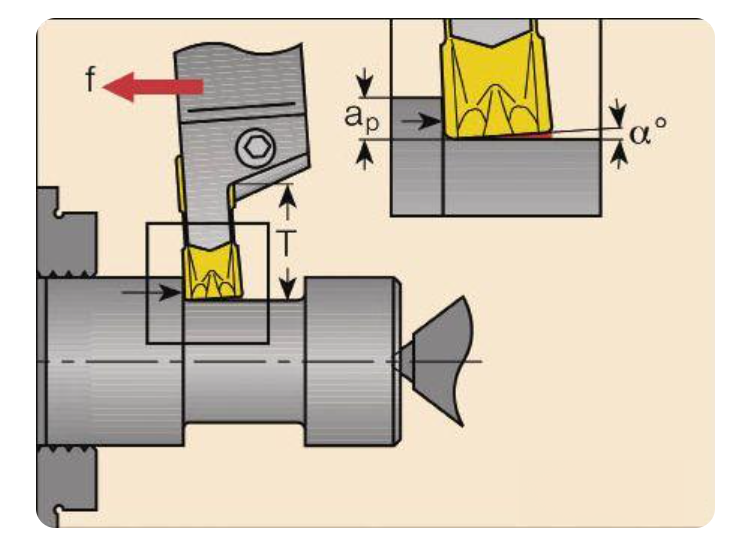

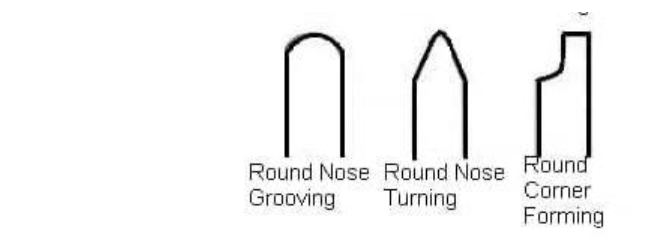

12. Ithuluzi lekhala eliyindilinga

Ukusika ikhala elijikelezayo kungachazwa njengethuluzi elisetshenziselwa ukuqeda imishini.Imimese yekhala eliyindilinga ayinalo uhlangothi noma i-rake yangemuva futhi ingasika kwezinye izindawo.

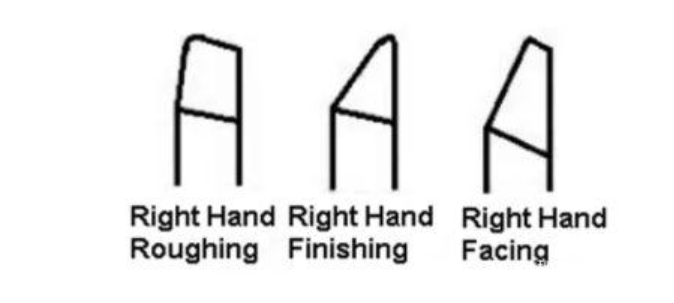

13. Ithuluzi lesandla sokudla

Ithuluzi elijika kwesokudla lisusa okubalulekile njengoba lisuka kwesokudla liye kwesokunxele (lidinga kuphela ukubuka okuphezulu, ukugcina ubuso beraki bungaphezulu).Igama lethuluzi lesandla sokudla lisetshenziswa ngokusekelwe ekufanisweni kwesandla somuntu.Ngesandla sokudla, isithupha simele isiqondiso sokuphakela kwethuluzi.Ngakho-ke, umkhawulo oyinhloko wokusika wethuluzi ungakwesokudla kwethuluzi.

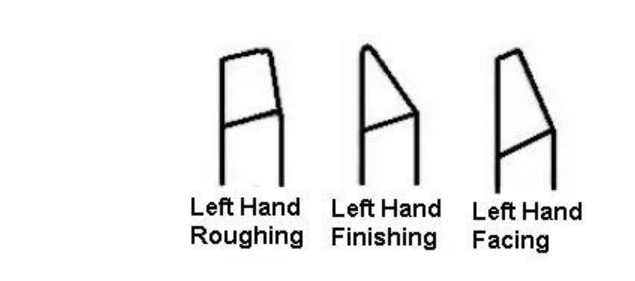

14. Amathuluzi angakwesokunxele

Ngokungafani namathuluzi angakwesokudla, amathuluzi asesandleni sobunxele asusa okokusebenza njengoba esuka kwesokunxele aye kwesokudla (ukubuka phezulu kugcina ubuso beraki bubonakala).Ngesandla sobunxele, isithupha simele isiqondiso sokuphakela kwethuluzi.Ngakho-ke, umkhawulo oyinhloko wokusika wethuluzi ungakwesokudla kwethuluzi.

Indlela yokukhetha ithuluzi le-lathe

Ukukhetha ithuluzi le-lathe kudinga ukuqonda izici ezithile ezihlobene nemishini.Okulandelayo yizici ezibaluleke kakhulu okufanele uzicabangele lapho ukhetha i-lathe:

uhlobo lwempahla

Uhlobo lwezinto ozisikile ziyisici esibalulekile ekunqumeni uhlobo lwethuluzi le-lathe ongalisebenzisa.Izimfanelo ezibalulekile okufanele uzinake ngaphambi kokukhetha ithuluzi lokuguqula zihlanganisa: ubulukhuni, ukumelana nokugqoka, ukuqina nokuqina.Lezi zakhiwo zidlala indima ebalulekile ezinhlotsheni zamathuluzi we-lathe ongawasebenzisa.Isibonelo, izinto eziqinile kakhulu zidinga amathuluzi e-carbide noma amadayimane.

umumo wethuluzi

Ukuma kwethuluzi le-lathe nakho kungenye into okufanele icatshangelwe lapho ukhetha.Ukuma konqenqema lokusika kuphinde kunqume indlela yokusika ithuluzi (kwesokudla, kwesokunxele, kanye nekhala eliyindingilizi).

umumo owenziwe ngomshini

Uhlobo ngalunye lwethuluzi le-lathe elifakwe ohlwini ngaphansi kokuhlukaniswa lungaholela kumumo oshiwo.Ngakho-ke, kufanele uhlanganise umumo oyifunayo ethuluzini lokujika elifiselekayo.Ngenxa yobunkimbinkimbi bemikhiqizo eminingi ye-CNC, ungase udinge ukukhetha inhlanganisela yamathuluzi amaningana e-lathe.

Isikhathi sokuthumela: Apr-24-2022