Ikhwalithi enhle yamathuluzi okuguqula i-lathe emishini ehlukene

Abasiki bezintambo banensimbi, i-CBN (i-cubic boron nitride), i-Ceramic, idayimane nezinye izinto.

Kukhona ama-lathe cutter ahlukene wokucubungula okuhlukile kwe-lathing, singakunikeza amathuluzi njengokusebenza kwakho.

Indlela yokukhetha ithuluzi le-lathe

Ukukhetha ithuluzi le-lathe kudinga ukuqonda izici ezithile ezihlobene nemishini.Okulandelayo yizici ezibaluleke kakhulu okufanele uzicabangele lapho ukhetha i-lathe:

uhlobo lwempahla

Uhlobo lwezinto ozisikile ziyisici esibalulekile ekunqumeni uhlobo lwethuluzi le-lathe ongalisebenzisa.Izimfanelo ezibalulekile okufanele uzinake ngaphambi kokukhetha ithuluzi lokuguqula zihlanganisa: ubulukhuni, ukumelana nokugqoka, ukuqina nokuqina.Lezi zakhiwo zidlala indima ebalulekile ezinhlotsheni zamathuluzi we-lathe ongawasebenzisa.Isibonelo, izinto eziqinile kakhulu zidinga amathuluzi e-carbide noma amadayimane.

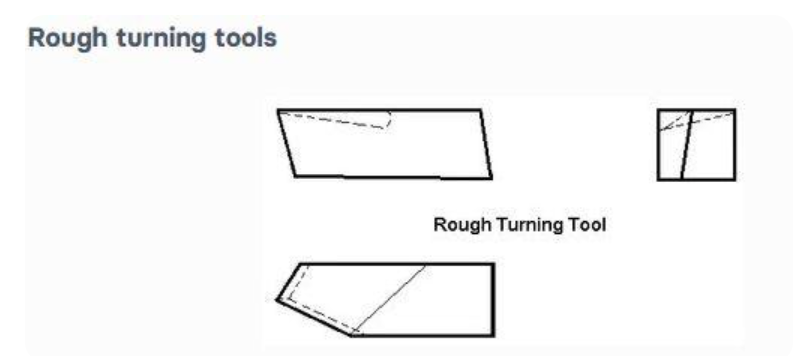

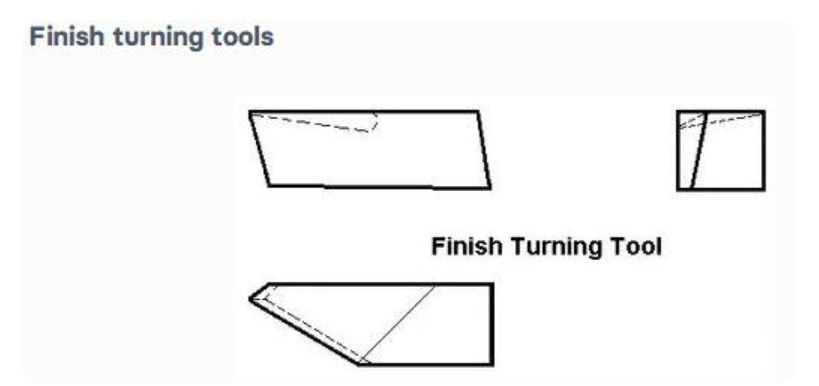

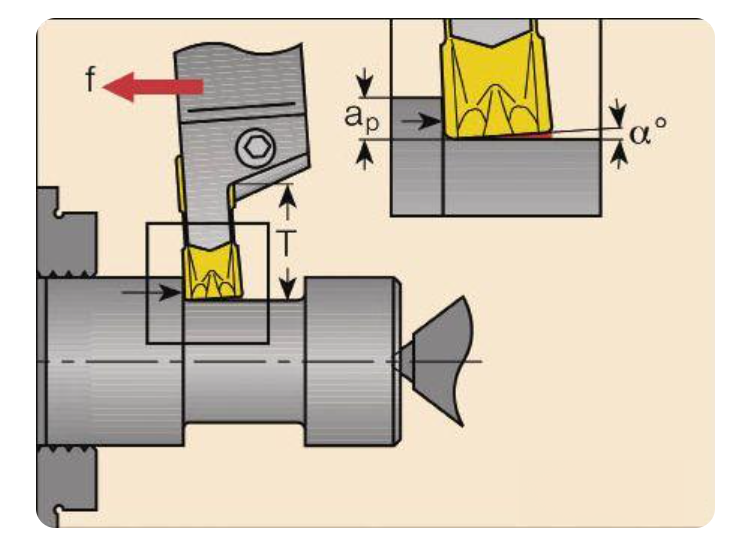

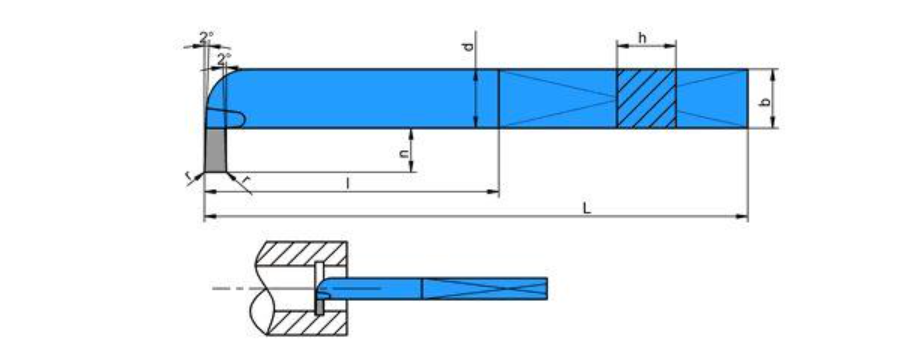

umumo wethuluzi

Ukuma kwethuluzi le-lathe nakho kungenye into okufanele icatshangelwe lapho ukhetha.Ukuma konqenqema lokusika kuphinde kunqume indlela yokusika ithuluzi (kwesokudla, kwesokunxele, kanye nekhala eliyindingilizi).

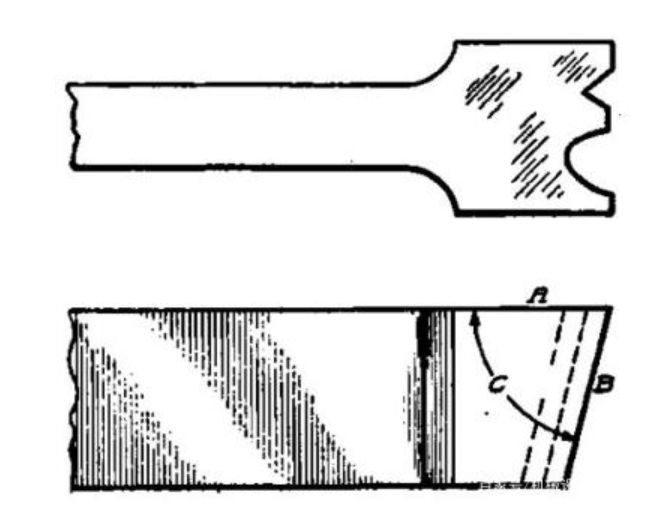

umumo owenziwe ngomshini

Uhlobo ngalunye lwethuluzi le-lathe elifakwe ohlwini ngaphansi kokuhlukaniswa lungaholela kumumo oshiwo.Ngakho-ke, kufanele uhlanganise umumo oyifunayo ethuluzini lokujika elifiselekayo.Ngenxa yobunkimbinkimbi bemikhiqizo eminingi ye-CNC, ungase udinge ukukhetha inhlanganisela yamathuluzi amaningana e-lathe.

Uhlobo lwe-lathe cutters:

1. Amathuluzi okusika intambo

2. Ithuluzi le-Chamfering

3. Amathuluzi okuguqula

4. Slotting ithuluzi

5. Qeda umsiki wobuso

6. Ithuluzi eliyisicefe

7. Ithuluzi lokwakha

8. Counter ithuluzi boring

9. Ithuluzi lokubuyisela kabusha

10. Ithuluzi lokusika

11. Amathuluzi okubhoboza

Amathuluzi okubhoboza nawo angamathuluzi abaluleke kakhulu kuma-lathes.Amathuluzi okumba asetshenziswa kakhulu umshini izimbobo cylindrical ku workpiece enikeziwe.Kulesi simo, i-workpiece igxiliwe kuphaneli, i-drill bit igxiliwe kuhlaka lokugaya i-tailstock, futhi umgodi kufanele ugcwaliswe ngokuhamba kwe-spindle ye-tailstock.Lokhu kusebenza kuma-workpieces anomumo ovamile.

B) Ngokwendlela yokuphakela isicelo:

Ahlukaniswe abe izinhlobo ezintathu:

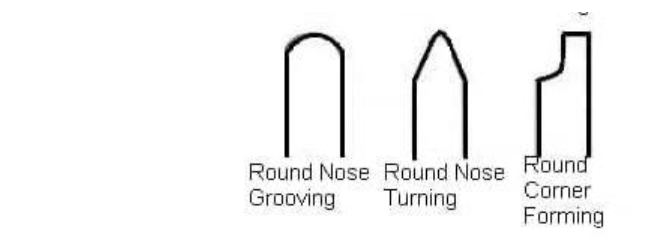

12. Ithuluzi lekhala eliyindilinga

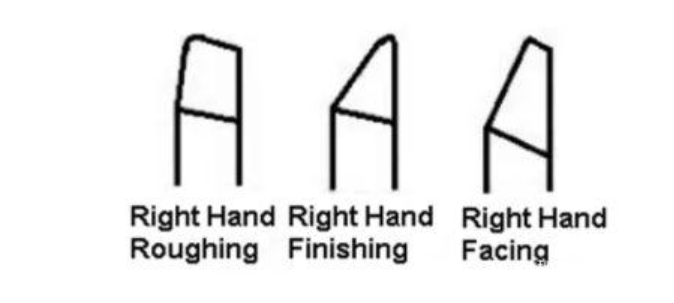

13. Ithuluzi lesandla sokudla

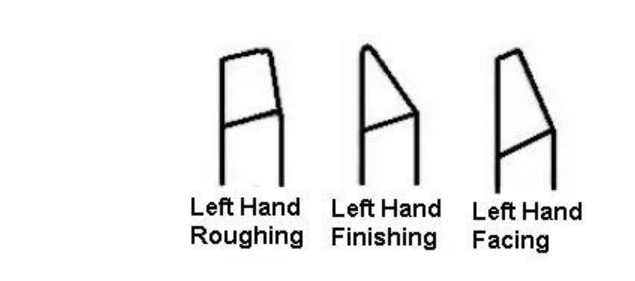

14. Amathuluzi angakwesokunxele

Ngokungafani namathuluzi angakwesokudla, amathuluzi asesandleni sobunxele asusa okokusebenza njengoba esuka kwesokunxele aye kwesokudla (ukubuka phezulu kugcina ubuso beraki bubonakala).Ngesandla sobunxele, isithupha simele isiqondiso sokuphakela kwethuluzi.Ngakho-ke, umkhawulo oyinhloko wokusika wethuluzi ungakwesokudla kwethuluzi.

Indlela yokukhetha ithuluzi le-lathe

Ukukhetha ithuluzi le-lathe kudinga ukuqonda izici ezithile ezihlobene nemishini.Okulandelayo yizici ezibaluleke kakhulu okufanele uzicabangele lapho ukhetha i-lathe:

uhlobo lwempahla

Uhlobo lwezinto ozisikile ziyisici esibalulekile ekunqumeni uhlobo lwethuluzi le-lathe ongalisebenzisa.Izimfanelo ezibalulekile okufanele uzinake ngaphambi kokukhetha ithuluzi lokuguqula zihlanganisa: ubulukhuni, ukumelana nokugqoka, ukuqina nokuqina.Lezi zakhiwo zidlala indima ebalulekile ezinhlotsheni zamathuluzi we-lathe ongawasebenzisa.Isibonelo, izinto eziqinile kakhulu zidinga amathuluzi e-carbide noma amadayimane.

umumo wethuluzi

Ukuma kwethuluzi le-lathe nakho kungenye into okufanele icatshangelwe lapho ukhetha.Ukuma konqenqema lokusika kuphinde kunqume indlela yokusika ithuluzi (kwesokudla, kwesokunxele, kanye nekhala eliyindingilizi).

umumo owenziwe ngomshini

Uhlobo ngalunye lwethuluzi le-lathe elifakwe ohlwini ngaphansi kokuhlukaniswa lungaholela kumumo oshiwo.Ngakho-ke, kufanele uhlanganise umumo oyifunayo ethuluzini lokujika elifiselekayo.Ngenxa yobunkimbinkimbi bemikhiqizo eminingi ye-CNC, ungase udinge ukukhetha inhlanganisela yamathuluzi amaningana e-lathe.