I-CNC Pipe Horizontal Honing Machine

I-CNC Pipe Horizontal Honing Machine yenzelwe amapayipi amade, isiza amakhasimende ahlukene afuna ukuqeda kahle emigodini.Umshini we-Honing ungacubungula ubuyindilinga, uqonde, uthayiphe, ukuqeda ubuhwaqane nokunye.

1. Umshini wokucija isakhiwo sebenzisa insimbi yokwelapha eshiselwe nokushisa ukuze uthole isakhiwo esiqinile ukuze unikeze ukwesekwa okuqinile kokucutshungulwa kwe-honing.Ngemva kokuhlangana, sasizosebenzisa i-anti-rust coating enopende omnyama wekhwalithi ephezulu;yenza i-casing ephezulu yethuluzi lomshini elifafazwe ngemuva kokunciphisa, ukulungiswa kwendawo kanye ne-phosphating.Umbala uyiPearl white (noma upende ngokwezidingo zekhasimende), umshini unokubukeka okuhle, imigqa ebushelelezi kanye nomuzwa wesimanje.

2. Ibhokisi lokuphotha lishayelwa i-vector frequency conversion motor ene-reduction ratio enkulu ye-hard-tooth surface gear reducer, engazuza amandla angaguquki.

Ukukhishwa kwe-torque ephezulu ngesivinini esikhulu, amandla okusika akhuphuka, futhi kulula ukusetha isivinini esilungile sokuphotha izingxenye ezinobubanzi obuhlukene bobhore.

Amandla e-spindle angu-5.5Kw, isivinini ngu-5-250r/min.(Amandla asekelwe kumthamo wokusika)

3. Isistimu yokwandisa okuphakelayo kwekhanda lokucija:

I-Servo motor feeding: Iyunithi yonke yokudla ifakwe ku-headstock, futhi i-servo motor inwetshwa ngedivayisi ekhethekile yokukhulisa ikhanda le-honing.

Ukunwetshwa okuzenzakalelayo (okubizwa nangokuthi ukuphakela) kwekhanda lokucija kuyabonakala.Le divayisi ixhunywe ngokuhambisana ne-shaft eyinhloko.Isistimu yonke inekhanda elilodwa le-honing , elinobubanzi obukhulu be-honing, isisindo esincane kanye nekhono lokuzikhiya, okusiza ukuthuthukisa ukunemba okuphezulu.Amandla e-servo motor anwetshiwe 400w;

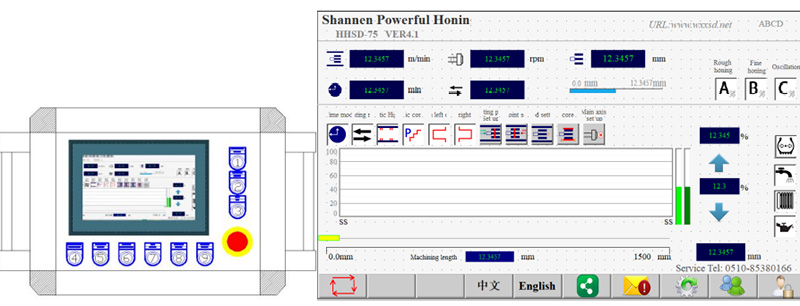

Inzuzo: Wonke umshini unikwa amandla kagesi.Iyunithi yokuphakelayo ingalungiswa kalula ukusuka ku-0.001-0.05mm.

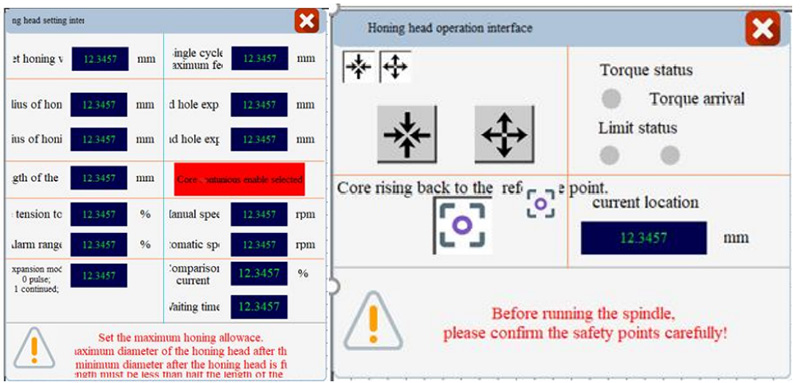

Kunezindlela ezintathu zokuphakela, isithombe esingezansi sikhombisa isixhumi esibonakalayo esinwebekayo sokulawula isikrini se-honing head.

4. Ukudluliselwa okuphindaphindayo: I-servo motor, i-planetary reducer kanye neketanga lokudlulisela kuhlanganiswe ukwenza isakhiwo somshini esinembayo esisheshayo esinembayo.

Amandla e-Servo motor 3.5KW.Ijubane elibuyiselayo ngu-1-30m/min.Ubude obusebenzayo bokubuyelana bungu-1.7m.Umbuthano wokulawula isilungiselelo sobude obulinganayo

Ubuso bumi kanje:

5. Uhlelo lokupholisa luwukugeleza okungu-100L/min, kanye nemodi yokukhipha uwoyela wokucija:

Uwoyela wokucija ogeleza kakhulu ujovwa ekugcineni kwepayipi lensimbi ukuze kufezwe ukuhlanza okuphumelelayo nokwandisa ukusebenza kahle kokugaya.Amafutha okucweba

Umthamo wethangi 200 amalitha, noma ngokwezifiso

Umjovo kawoyela ulawulwa isikrini esithintwayo, ukuze umjovo umise ukundiza Uma ikhanda lokucija lifika emaphethelweni womabili wepayipi lensimbi.

Ngokucutshungulwa kwezinto ezihlukene, singahlinzeka ngesistimu yokuhlunga ehlukene, isibonelo, insimbi kazibuthe, sizosebenzisa isistimu yesihlukanisi kazibuthe, ezintweni ezingezona kazibuthe, singakhetha uhlelo lokuhlunga iphepha noma isihlungi sephepha lokucindezela.

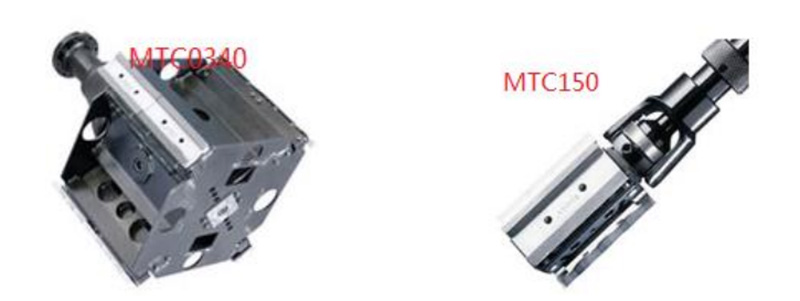

6. Induku yokucija: Sinamakhanda amaningi okucija ukumboza u-35-350mm, noma enziwe ngezifiso.Isibonelo imodeli

①MGC1532 icubungula imbobo ububanzi 38-58mm

②MGC1550 icubungula imbobo ububanzi 60-150mm

Ingaphezulu le-honing rod lingaphansi kokucinywa kwe-high-frequency bese kuba i-cylindrical honing, futhi ukuphela kwendawo kufinyelela ku-Ra0.2um.

Imbobo yangaphakathi ye-workpiece ngeke ilimaze ubushelelezi be-workpiece.Zombili iziphetho ze-honing rod zixhunywe emhlabeni wonke ukuze kunxeshezelwe ngokuzenzakalelayo i-spindle kanye nokugxila kwembobo yangaphakathi yesiqephu.

7. I-clamp yensimbi ye-v-type clamp iyafana ne-American Sunnen deep hole machine, i-clamping diameter yangaphandle ingu-40-250mm, noma ngokwezifiso.

8. Amakhanda okucija imbobo ejulile: hlinzeka ngekhanda lokugaya elidingekayo ngokwezidingo zenkampani yakho (ngezansi kunezimo zesibonelo).

9. Uhlelo lokulawula: kusetshenziswa isikrini sokuthinta + isilawuli se-PLC, unjiniyela wethu ochwepheshile uklama isoftware eyodwa ehlakaniphile yokucija ukucubungula.Lapho usebenzisa umshini, amathuluzi okucija, isivinini esidingekayo, ukuphindaphinda, ukuphakela, ukupholisa, njll. kulula ukusethwa, futhi ulandelele ukucubungula ku-inthanethi , ukuze opharetha balawule futhi bathole ukuqedela okuhle ngomshini wethu wokucija .

Ukusebenza kusethwe kusikrini esiqinile ukwenza ukusebenza kube lula.Uhlelo lwethu lokulandela ngomkhondo lwe-inthanethi lusebenza kahle kakhulu ukuze kuzuzwe ukusebenza okulula.Lolu hlelo lulandelela isimo sokusebenza sethuluzi lomshini kanye nokunemba kwezingxenye, ukuze lilungiswe ngesikhathi ukuze kugwenywe ukukhiqizwa kwemfucuza nokonakaliswa kwemishini.Ngesikhathi esifanayo, ukuze kuqinisekiswe ukuhambisana kobubanzi bomgodi wangaphakathi wepayipi lensimbi,

Isikrini sokuthinta samukela isakhiwo esime mpo futhi singaguqulwa sibe ngamadigri angu-180.Isikrini esithintwayo sikhala ngokuzenzakalelayo lapho ithuluzi lomshini lihlangabezana nephutha.

Amaphutha alandelayo (kunezindlela ezihlukile zokucaphuna ngokuya ngokucushwa komshini):

1. Imodi yomshini ayikhethiwe i-alamu 2. Indawo yereferensi yokuqala yesiphakeli ayimisiwe.

3. Isikhathi sokucubungula kwimodi yesikhathi asisethiwe.4. Umsuka womshini noma uhla lokucubungula alusethiwe ngokuphelele

5. Ukulungiselelwa kwepharamitha yembobo eyimpumputhe akuphelele 6. Ukulungiselelwa kwepharamitha ye-eksisi yesiphakeli akuphelele

7. Amapharamitha ophimbo awasethiwe ngokuphelele 8 I-alamu yokuhluleka kwezingxenyekazi zekhompuyutha

10. Ezokuphepha

Iphaneli yokulawula inenkinobho ye-e-stop, engacindezelwa ukuze kumiswe ithuluzi lomshini esimweni esiphuthumayo.Zombili izinhlangothi zikamzila wesitimela zifakwe izinto ezivikela indawo

I-shaft eyinhloko ifakwe isembozo sokuzivikela ukuze kuvikelwe opharetha.

Ulwazi lwephutha elivamile lephaneli yokulawula:

1. Imodi yomshini ayikhethiwe i-alamu 2. Indawo yereferensi yokuqala yesiphakeli ayimisiwe.

3. Isikhathi sokucubungula kwimodi yesikhathi asisethiwe.4. Umsuka womshini noma uhla lokucubungula alusethiwe ngokuphelele

5. Ukulungiselelwa kwepharamitha yembobo eyimpumputhe akuphelele 6. Ukulungiselelwa kwepharamitha ye-eksisi yesiphakeli akuphelele

7. Amapharamitha ophimbo awasethiwe ngokuphelele 8 I-alamu yokuhluleka kwezingxenyekazi zekhompuyutha