Abasiki be-lathes yintsimbi, i-CBN (i-cubic boron nitride), i-Ceramic, idayimane kunye njl.

Iintlobo zezixhobo zokusika i-lathe:

Ngokuxhomekeke kwisicelo, izixhobo zokusika i-lathe zihlulwe ngokwesiseko zibe ziindidi ezimbini:

A) Ngokwendlela isixhobo esisetyenziswa ngayo.

B) Indlela yokutyisa ngokwesicelo

A) Kuxhomekeke kwindlela isixhobo esisetyenziswa ngayo:

Kukho iindidi ezili-11 zeemela:

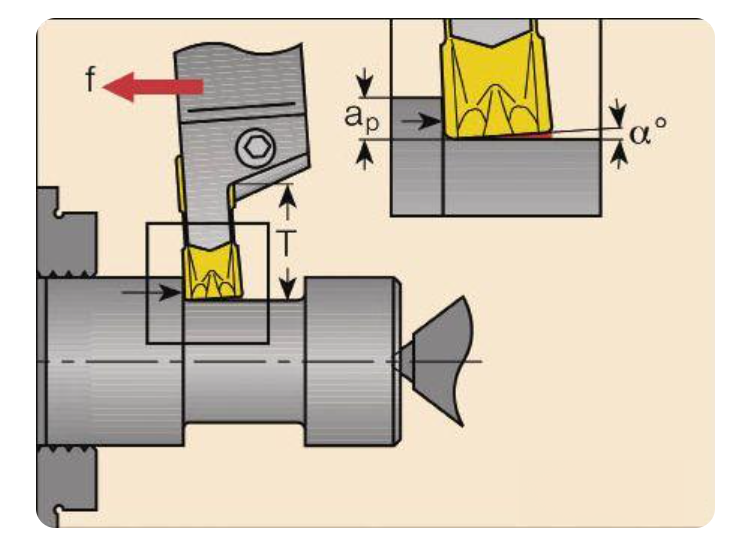

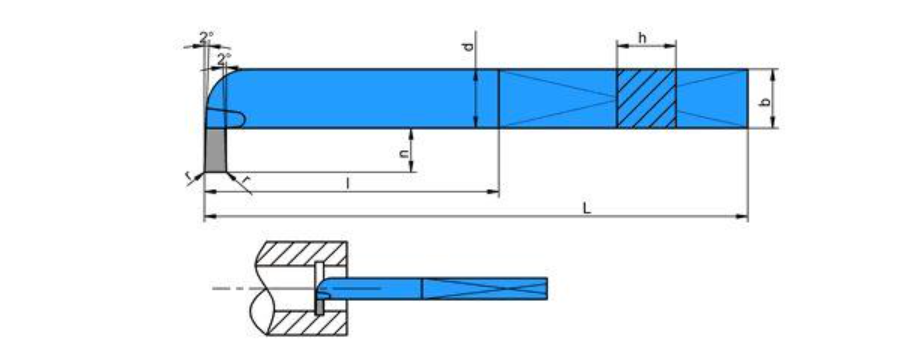

1. Izixhobo zokusika imisonto

Zimbini iindidi:

Izixhobo ezifakwe kwimisonto yangaphandle-Izixhobo ezifakwe ngaphandle ziyaziwa njengezixhobo zokuthunga.Zichazwa njengezixhobo zokwenza imicu yangaphandle yee-workpieces.

Isixhobo somsonto wangaphakathi-Isixhobo somsonto sangaphakathi sichazwa njengesixhobo esisetyenziselwa ukutshiza imisonto yangaphakathi kwindawo yokusebenza.

2. isixhobo Chamfering

Isixhobo se-chamfering sinokuchazwa njengesixhobo esisetyenziselwa ukuyila ii-bevels okanye iigrooves kwiibholiti.Ezi zixhobo zisetyenziselwa ukukrazula iikona zezinto zokusebenza.Xa isixa esikhulu se-chamfering sifuneka, isixhobo esithile se-chamfering esinee-chamfers zecala siyafuneka.

3. Ukuguqula izixhobo

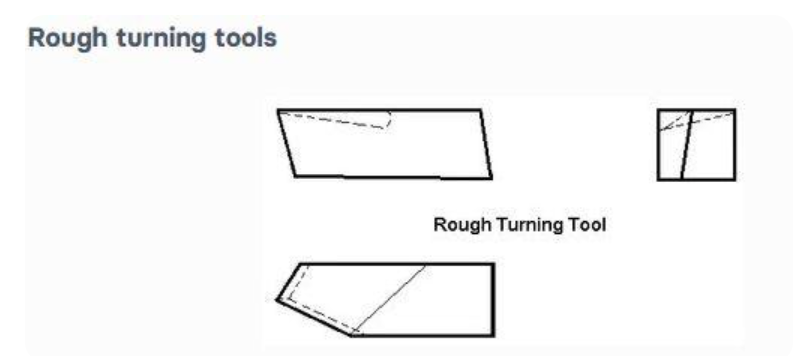

Kukho iintlobo ezimbini zezixhobo zokuguqula ngokubanzi:

Izixhobo zokuguqula i-rough - Izixhobo eziguquguqukayo zisetyenziselwa ukususa ubuninzi bentsimbi ngexesha elifutshane.Kwaye i-angle yokusika icacile kwaye inokumelana namandla amakhulu okusika.

Ii-Fine Turning Knives - Izixhobo zokuguqula kakuhle zisetyenziselwa ukususa ixabiso elincinci letsimbi.I-angle yokusika nayo iphantsi ukuze ivelise indawo epholileyo kunye nechanekileyo

4. Isixhobo sokubeka

Izixhobo ze-grooving zichazwa ngokusisiseko njengezixhobo ezisetyenziselwa ukudala i-cavity emxinwa yobunzulu obuthile kwi-cone, i-cylinder okanye umphezulu wenxalenye.Kule meko, imilo ethile yesixhobo se-grooving kufuneka ikhethwe ngokubhekiselele ekubeni i-grooves ye-edge cutting are square, round, njl.

5. Qeda umsiki wobuso

Isixhobo sobuso sinokuchazwa njengesixhobo esisetyenziselwa ukusika i-plane perpendicular to the axis of rotation of the workpiece.Isixhobo sobuso sithwalwa ngumnini wesixhobo esisisigxina kumatshini ophethe umatshini.Isetyenziselwa ukunciphisa ubude bomsebenzi ngokunikezela nge-perpendicular kwi-axis ye-lathe.Umgca wokusika wesixhobo kufuneka ubekwe kwindawo ephakamileyo njengeziko lomsebenzi.

6. Isixhobo esikruqulayo

Ukudika sisixhobo esisetyenziselwa ukukhulisa imingxuma.Xa ufuna ukwandisa umngxuma okhoyo, kufuneka usebenzise ibha ekruqulayo.Imivalo ekruqulayo inokugrunjwa ngokulula kwimingxuma esele yombiwe kwaye yandiswe ngobubanzi.Inokubuyiselwa ngokukhawuleza kubungakanani bokufakelwa ngokufanelekileyo kwamanye amacandelo.

7. Isixhobo sokubumba

Izixhobo zokubumba zinokuchazwa njengezixhobo ezisetyenziselwa ukudala iintlobo ezahlukeneyo zeemilo zeworkpiece.Kule meko, uhlobo olukhethekileyo lwekhava okanye umnini lusetyenziselwa ukubamba isixhobo sokwenza.Ukusuka koku senza iindidi ezahlukeneyo zokusebenza, ezifana nokwenza iradiyasi yangaphakathi, iradiyasi yangaphandle, njl.

8. Counter isixhobo ekruqulayo

Isixhobo esinesithukuthezi esingasemva sinokuchazwa njengesixhobo esisetyenziselwa ukukhulisa kunye nokubeka intloko yesokhethi yesikrufu okanye ibholiti.Esi sixhobo sineemitha ezimbini:

A) Yenza imingxuma esele igrunjwe ngaphambili

B) Gqoka imingxuma kwindawo yokusebenza

9. Isixhobo sokuhlaziya

Isixhobo sokubuyisela kwakhona sichazwa njengesixhobo esisetyenziselwa ukugqiba kunye nokunyamezela kwe-dimensional yemingxuma ebhobholweyo okanye egrunjiweyo.

10. Isixhobo sokusika

Izixhobo ze-Undercutting zifana nezixhobo zokugoba.Kule meko, isixhobo esisezantsi sisetyenziselwa ukubhoboza imingxuma emikhulu kumgama osisigxina ukusuka ekupheleni komngxuma.I-undercutting yenziwa ngokuyinhloko kumsonto wangaphakathi ukuze kuhlanjululwe.

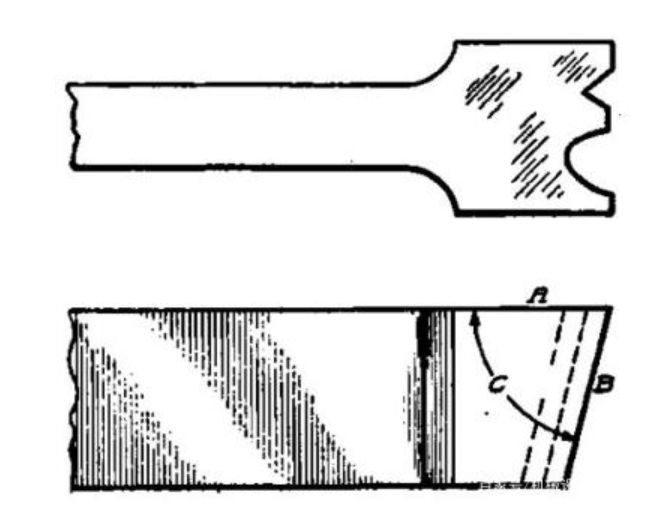

11. Izixhobo zokugaya

Izixhobo zokugaya zikwabaluleke kakhulu kwiileyile.Izixhobo zokugaya zisetyenziselwa ikakhulu umatshini wemingxuma ye-cylindrical kwi-workpiece enikiweyo.Kule meko, i-workpiece igxininiswe kwipaneli, i-drill drill igxininiswe kwisakhelo se-tailstock drill, kwaye umngxuma kufuneka ugqitywe ngokuhamba kwe-spindle tailstock.Oku kusebenza kwii-workpieces ezimile rhoqo.

B) Ngokwendlela yokutya yesicelo:

Zahlulwe zaba ziindidi ezintathu:

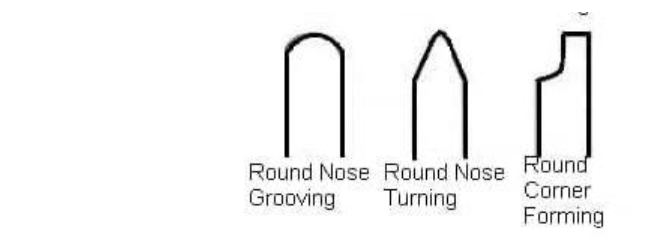

12. Isixhobo sempumlo esijikelezayo

Ukusikwa kweempumlo ezijikelezayo kunokuchazwa njengesixhobo esisetyenziselwa ukugqiba umatshini.Iimela zempumlo ezingqukuva azinacala okanye iharika yangasemva kwaye zinokusikela kwelinye icala.

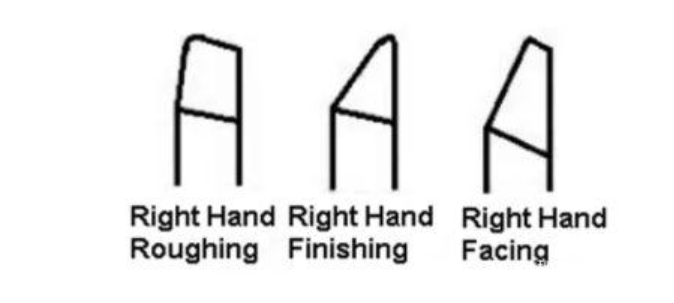

13. Isixhobo sesandla sasekunene

Isixhobo sokuguqula isandla sasekunene sisusa izinto njengoko sihamba ukusuka ekunene ukuya ekhohlo (sifuna kuphela umbono ophezulu, ukugcina ubuso beraki phezulu).Igama lesixhobo sesandla sokunene lisetyenziswe ngokusekelwe kwisifaniso sesandla somntu.Ngesandla sasekunene, ubhontsi umele isalathiso sokutya kwesixhobo.Ngoko ke, eyona nto iphambili yokusika isixhobo kwicala lasekhohlo lesixhobo.

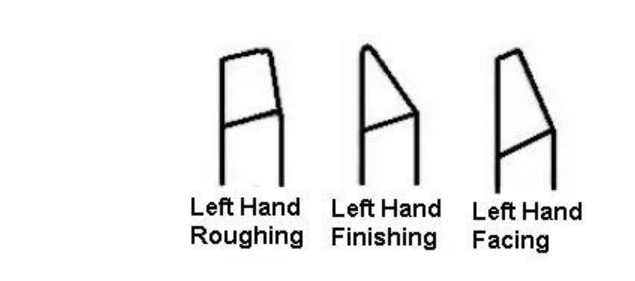

14. Izixhobo ezisekhohlo

Ngokungafaniyo nezixhobo zokujika zasekunene, izixhobo ezisekhohlo zisusa izinto njengoko zihamba ukusuka ekhohlo ukuya ekunene (umbono ophezulu ugcina ubuso beraki bubonakala).Ngesandla sasekhohlo, ubhontsi umele icala lesixhobo sokutya.Ngoko ke, eyona nto iphambili yokusika isixhobo ikwicala lasekunene lesixhobo.

Indlela yokukhetha isixhobo se-lathe

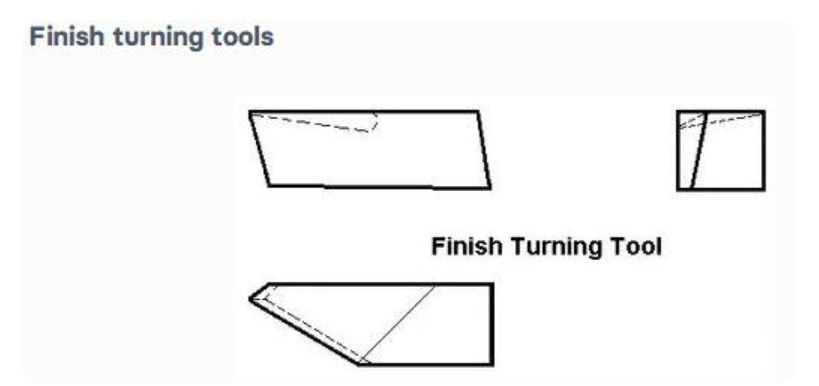

Ukukhetha isixhobo se-lathe kufuna ukuqonda izinto ezithile ezinxulumene nesixhobo.Oku kulandelayo yimiba ebaluleke kakhulu ekufuneka uyiqwalasele xa ukhetha i-lathe:

uhlobo lwezinto

Uhlobo lwemathiriyeli osikiweyo luyinto esisiseko ekumiseleni uhlobo lwesixhobo selathe onokusisebenzisa.Iimpawu ezibalulekileyo kufuneka ubeke ingqalelo phambi kokukhetha isixhobo sokuguqula ziquka: ukuqina, ukuxhathisa, ukuqina kunye nokuqina.Ezi zakhiwo zidlala indima ebalulekileyo kwiintlobo zezixhobo ze-lathe onokuzisebenzisa.Ngokomzekelo, izinto ezinzima kakhulu zifuna izixhobo ze-carbide okanye idayimane.

ubume besixhobo

Ubume besixhobo se-lathe kwakhona enye into ekufuneka uyiqwalasele xa ukhetha.Isikhundla somgca wokusika kwakhona simisela isalathiso sokusika isixhobo (isandla sasekunene, sasekhohlo, kunye neempumlo ezijikelezayo).

imilo eyenziwe ngoomatshini

Uhlobo ngalunye lwesixhobo se-lathe esidweliswe phantsi kolwahlulo lunokubangela kwimilo echaziweyo.Ngoko ke, kufuneka udibanise imilo efunekayo kwisixhobo esifunekayo sokuguqula.Ngenxa yokuntsokotha kweemveliso zoomatshini abaninzi be-CNC, unokufuna ukukhetha indibaniselwano yezixhobo ezininzi ze-lathe.

Ixesha lokuposa: Apr-24-2022