Umbhobho we-CNC oHolizonti woMshini wokuHola

I-CNC Pipe Horizontal Honing Machine yenzelwe imibhobho emide, inceda abathengi abahlukeneyo abafuna ukufumana ukugqiba kakuhle kwimingxuma.Umatshini wokuhombisa unokucubungula ukujikeleza, ngokuthe tye, kwe-taper, ukugqibezela uburhabaxa kunye nokunye.

1. Umatshini wokuhombisa isakhiwo usebenzisa i-welded kunye nentsimbi yonyango lobushushu ukufumana isakhiwo esomeleleyo sokubonelela ngenkxaso eyomeleleyo yokulungisa i-honing.Emva kokuba sidityanisiwe, besiza kusebenzisa i-anti-rust coating kunye nepeyinti emnyama yodidi oluphezulu;yenza i-casing ephezulu yesixhobo somatshini esitshiziweyo emva kokunciphisa, ukulungiswa kwendawo kunye ne-phosphating.Umbala yiPearl emhlophe (okanye ipeyinti ngokweemfuno zomthengi), umatshini unenkangeleko entle, imigca egudileyo kunye nengqiqo yanamhlanje.

2. Ibhokisi yokuphotha iqhutywa yi-vector frequency conversion motor enomlinganiselo omkhulu wokunciphisa i-hard-tooth surface gear reducer, enokufikelela kumandla angaguqukiyo.

Ukukhutshwa kwetorque ephezulu ngesantya esiphezulu, ukonyuka kwamandla okusika, kwaye kulula ukuseta isantya esichanekileyo sokuphotha kwiindawo ezinobubanzi obuhlukeneyo.

amandla Spindle 5.5Kw, isantya 5-250r / min.(Amandla asekelwe kumthamo wokusika)

3. Inkqubo yokwandiswa kwesondlo sentloko:

I-Servo motor feeding: Yonke iyunithi yokutya ifakwe kwi-headstock, kwaye i-servo motor iyandiswa ngesixhobo esikhethekileyo sokwandisa intloko.

Ukwandiswa okuzenzekelayo (okukwabizwa ngokuba kukutya) kwentloko ye-honing kuyenzeka.Esi sixhobo sixhunyiwe ngokuhambelana ne-shaft ephambili.Yonke inkqubo inentloko enye ye-honing , enoluhlu olukhulu lwe-honing, ubunzima obulula kunye nokukwazi ukuzivalela, okunceda ukuphucula ukuchaneka okuphezulu.Amandla e-servo motor eyandisiweyo 400w;

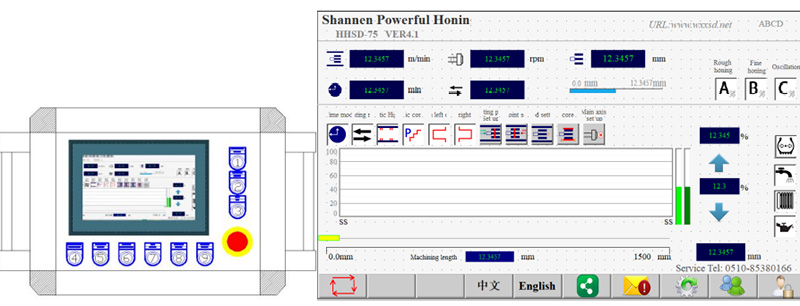

I-advanteji: Umatshini wonke uqhutywa ngumbane.Iyunithi yokutya inokulungiswa ngokulula ukusuka kwi-0.001-0.05mm.

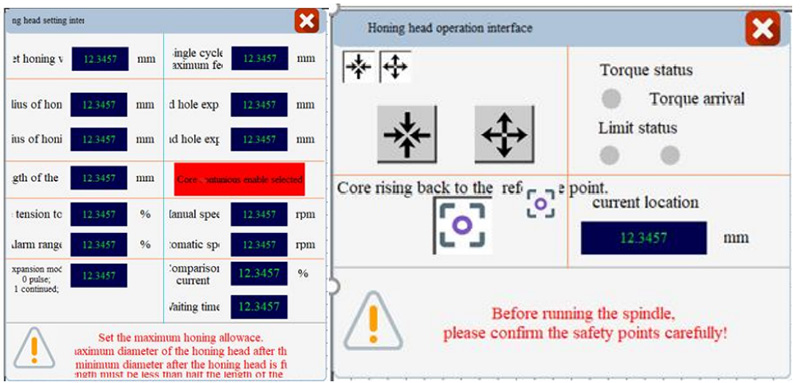

Kukho iindlela ezintathu zokutyisa, lo mfanekiso ungezantsi ubonisa ujongano lolwandiso lwescreen sokuchukumisa ihoning yentloko.

4. Ukuhanjiswa okuphindaphindiweyo: I-servo motor, i-planetary reducer kunye ne-transmission chain idibaniswe ukuze yenze i-high-precision fast reciprocating machine structure.

Servo motor amandla 3.5KW.Isantya esibuyiselayo si-1-30m/min.Ubude obubuyiselayo obusebenzayo yi-1.7m.Isangqa solawulo lokucwangcisa ubude obubuyiselanayo

Ubuso bumi ngolu hlobo lulandelayo:

5. Inkqubo yokupholisa ukuhamba kwe-100L / min, kunye nemodi yokukhupha ioli ye-honing:

Ioli ye-honing ephezulu ifakwe ekupheleni kombhobho wensimbi ukufezekisa ukucoca ngokufanelekileyo kunye nokwandisa ukusebenza kakuhle kokugaya.Ioli yokucoca

Umthamo wetanki iilitha ezingama-200, okanye ulungiselelwe wena

Isitofu se-oyile silawulwa yi-touch screen, ukwenzela ukuba inaliti inokuyeka i-jetting Xa intloko ye-honing ifikelela kuzo zombini iziphelo zepayipi yensimbi.

Ukulungiswa kwezinto ezahlukeneyo, siya kubonelela ngenkqubo yokucoca eyahlukileyo, umzekelo, kwintsimbi yemagneti, siya kusebenzisa inkqubo yokwahlula imagnethi, kwizinto ezingezizo ezemagneti, singakhetha inkqubo yokucoca iphepha okanye isihluzo sephepha loxinzelelo.

6. Intonga ye-Honing: Sineentloko ezininzi zokugubungela i-35-350mm, okanye i-customized.Umzekelo imodeli

①MGC1532 umngxuma wokusetyenzwa ubukhulu 38-58mm

②MGC1550 ukusetyenzwa komngxuma ububanzi 60-150mm

Umphezulu wentonga ye-honing iphantsi kokucima i-high-frequency quenching kwaye emva koko i-cylindrical honing, kunye nokugqitywa komphezulu kufikelela kwi-Ra0.2um.

Umngxuma wangaphakathi we-workpiece awuyi konakalisa ukugudiswa komsebenzi.Zomibini iziphelo zentonga ye-honing zixhunywe kwihlabathi jikelele ukuhlawula ngokuzenzekelayo i-spindle kunye nokugxila kwengxuma yangaphakathi yesiqhekeza.

7. Ityhubhu yentsimbi ye-v-type clamp iyafana ne-American Sunnen deep honing machine, i-clamping yangaphandle ye-diameter yi-40-250mm, okanye ngokwezifiso.

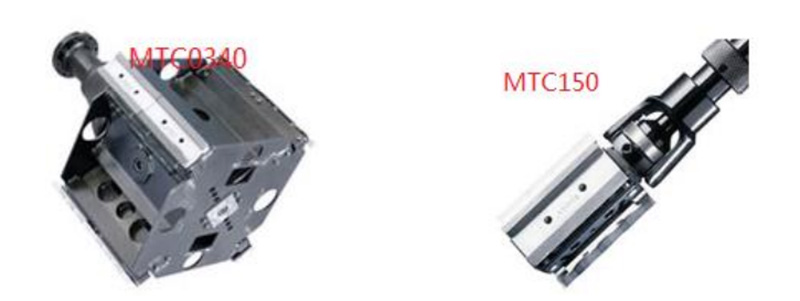

8. Iintloko zokuhomba umngxuma onzulu: bonelela ngentloko yokusila efunekayo ngokweemfuno zenkampani yakho (ngezantsi kweemilo zemizekelo).

9. Inkqubo yokulawula: usebenzisa isikrini sokuchukumisa + ulawulo lwe-PLC, injineli yethu yobuchwephesha iyila isoftware enye enobuchule bokuhombisa.Xa usebenzisa umatshini, izixhobo zokuhombisa, isantya esifunekayo, ukubuyisela, ukondla, ukupholisa, njalo njalo, kulula ukuseta, kunye nokulandelela ukusetyenzwa kwi-intanethi, ukuze abaqhubi balawule kwaye bagqibe kakuhle ngomatshini wethu wokuhombisa.

Ukusebenza kusetelwe kwiscreen esinzima ukwenza umsebenzi ube lula.Inkqubo yethu yokulandelela i-intanethi ngumsebenzi olungileyo kakhulu ukufezekisa ukusebenza okulula.Le nkqubo ilandelela imeko yokusebenza yesixhobo somatshini kunye nokuchaneka kwamacandelo, ukuze ulungelelanise ngexesha ukuphepha ukuveliswa kwenkunkuma kunye nomonakalo wezixhobo.Ngexesha elifanayo, ukwenzela ukuqinisekisa ukuhambelana kobubanzi bomngxuma wangaphakathi wombhobho wensimbi,

Isikrini sokuchukumisa sithatha isakhiwo esithe nkqo kwaye sinokujikwa ngamadigri angama-180.Isikrini sokuchukumisa ngokuzenzekelayo xa isixhobo somatshini sidibana nempazamo.

Iimpazamo zilandelayo (kukho iindlela ezahlukeneyo zocaphulo ngokobumbeko lomatshini):

1. Imo yomatshini ayikhethwanga i-alam 2. Indawo yereferensi yokuqala yefidi ayimiselwanga.

3. Ixesha lokucubungula kwimowudi yexesha alimiselwanga.4. Imvelaphi yomatshini okanye uluhlu lokucubungula alumiselwanga ngokupheleleyo

5. Ukucwangcisa ipharamitha yomngxuma oyimfama akugqitywanga

7. Iiparamitha ze-spindle azimiselwanga ngokupheleleyo 8 i-alamu yokusilela kwe-Hardware

10. Ukhuseleko

Iphaneli yokulawula ineqhosha le-e-stop, elinokuthi licinezele ukumisa isixhobo somatshini kwimeko kaxakeka.Omabini amacala omzila wesikhokelo axhotyiswe ngezixhobo zokukhusela isikhundla

I-shaft ephambili ifakwe kunye nekhava yokukhusela ukukhusela abaqhubi .

Iphaneli yokulawula ulwazi lwempazamo eqhelekileyo:

1. Imo yomatshini ayikhethwanga i-alam 2. Indawo yereferensi yokuqala yefidi ayimiselwanga.

3. Ixesha lokucubungula kwimowudi yexesha alimiselwanga.4. Imvelaphi yomatshini okanye uluhlu lokucubungula alumiselwanga ngokupheleleyo

5. Ulungiselelo lweparameter yomngxuma oyimfama alugqitywanga

7. Iiparamitha ze-spindle azimiselwanga ngokupheleleyo 8 i-alamu yokusilela kwe-Hardware