Iwo anocheka lathes isimbi, CBN (cubic boron nitride), Ceramic, diamond uye nezvimwe.

Mhando dzeLathe Cutting Tools:

Zvichienderana nekushandiswa, lathe yekucheka maturusi akakamurwa kuva marudzi maviri:

A) Zvinoenderana nemashandisirwo akaitwa chishandiso.

B) Nzira yekudyisa maererano nekushandiswa

A) Zvichienderana nekuti chishandiso chinoshandiswa sei:

Kune marudzi gumi nerimwe emapanga:

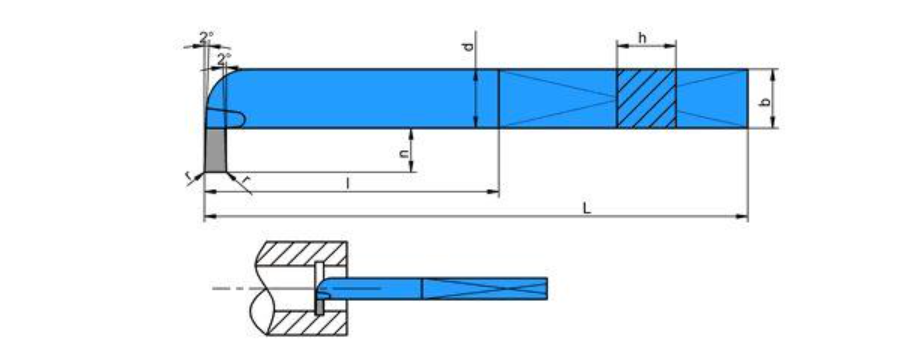

1. Zvishandiso zvekucheka tambo

Iwo ndeemhando mbiri:

Zvekunze Akarukwa Zvishandiso - Zvekunze zvakarukwa maturusi anozivikanwawo sematurusi ekugadzira.Iwo anotsanangurwa sematurusi ekugadzira ekunze shinda dzeworkpieces.

Chishandiso cheshinda chemukati-Chishandiso chemukati cheshinda chinotsanangurwa semudziyo unoshandiswa kugadzira shinda dzemukati muchidimbu chebasa.

2. Chamfering tool

Chishandiso chechamfering chinogona kutsanangurwa sechishandiso chinoshandiswa kugadzira mabhero kana grooves pamabhaudhi.Aya maturusi anoshandiswa kufambisa makona ezvishandiso.Kana huwandu hukuru hwechamfering huchidikanwa, chaiyo chamfering chishandiso chine mativi chamfers inodiwa.

3. Kushandura zvishandiso

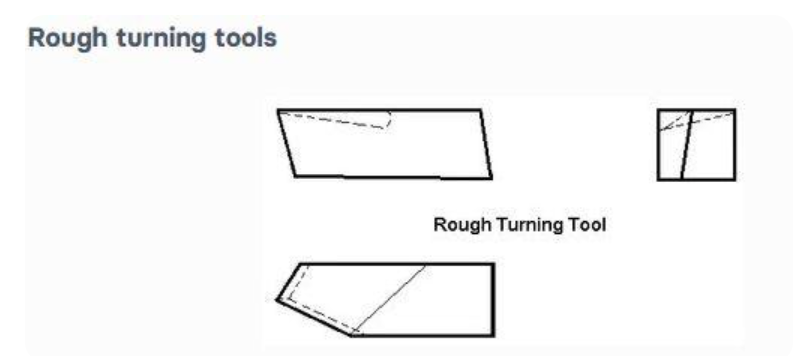

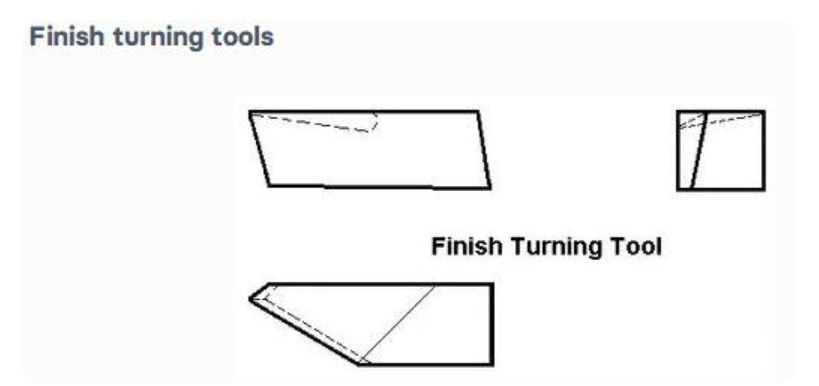

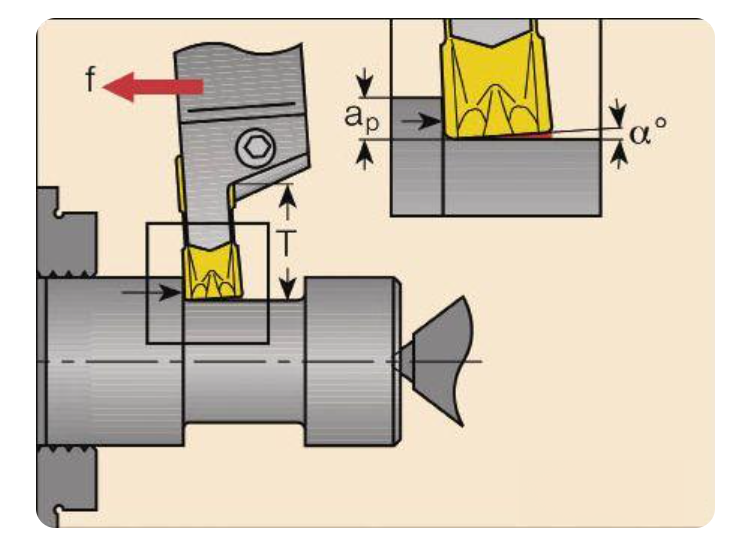

Pane kazhinji mhando mbiri dzematurusi ekutenderedza:

Rough Turning Tools - Maturusi ekushandura anoshandiswa kubvisa simbi yakakura munguva pfupi.Uye kona yekucheka yakajeka uye inogona kumira simba guru rekucheka.

Fine Turning Knives - Zvishandiso zvakanaka zvinoshandura zvinoshandiswa kubvisa zviduku zvesimbi.Iyo kona yekucheka inoiswawo pasi kuti ibudise nzvimbo yakatsetseka uye chaiyo

4. Slotting tool

Zvishandiso zvegrooving zvinotsanangurwa sezvishandiso zvinoshandiswa kugadzira gomba rakatetepa reimwe kudzika mukoni, silinda kana pamusoro pechikamu.Muchiitiko ichi, iyo chaiyo chimiro che grooving tool inofanira kusarudzwa zvichienderana nokuti grooves yekucheka kumucheto ndeye square, round, etc.

5. Kupedza face cutter

Chishandiso chechiso chinogona kutsanangurwa sechishandiso chinoshandiswa kucheka ndege perpendicular kune axis yekutenderera kweiyo workpiece.Chishandiso chechiso chinotakurwa nemudziyo wemudziyo wakagadzirirwa kumutakuri wemashini.Inoshandiswa kuderedza kureba kwechishandiso nekupa iyo perpendicular kune axis ye lathe.Kucheka kwechigadzirwa kunofanira kuiswa pahupamhi hwakafanana nechepakati pebasa rekushanda.

6. Boring tool

Boring chishandiso chinoshandiswa kukudza makomba.Paunenge uchida kukudza gomba riripo, unofanirwa kushandisa bhara rinofinha.Mabhawa anobhowa anogona kucherwa zviri nyore mumakomba akatoboorwa uye akawedzera dhayamita.Inogona kukurumidza kudzokororwa kuhukuru hwekuiswa kwakakodzera kwezvimwe zvikamu.

7. Kugadzira chishandiso

Maturusi ekugadzira anogona kutsanangurwa sematurusi anoshandiswa kugadzira akasiyana marudzi eworkpiece maumbirwo.Muchiitiko ichi, rudzi rwakakosha rwevhavha kana chibatiso chinoshandiswa kubata chigadziro chekugadzira.Kubva pane izvi tinoita marudzi akasiyana-siyana ekushanda, sekugadzira radius yemukati, yekunze radius, nezvimwe.

8. Counter boring tool

Chishandiso chekumashure chinofinha chinogona kutsanangurwa sechishandiso chinoshandiswa kukudza uye kutsvaga socket musoro wescrew kana bhaudhi.Ichi chishandiso chine maviri radii:

A) Gadzira makomba akafanocherwa

B) Dhonza maburi mune workpiece

9. Reming tool

A reming tool inotsanangurwa semudziyo unoshandiswa kupedzisa uye kushivirira kwedimensional yemakomba akacherwa kana kucherwa.

10. Undercutting tool

Undercutting zvishandiso zvakafanana negrooving maturusi.Muchiitiko ichi, chigadziro chepasi chinoshandiswa kubereka maburi mahombe pachinhambwe chakasarudzika kubva kumagumo egomba.Undercutting inonyanya kuitwa pane yemukati shinda yekuchenesa.

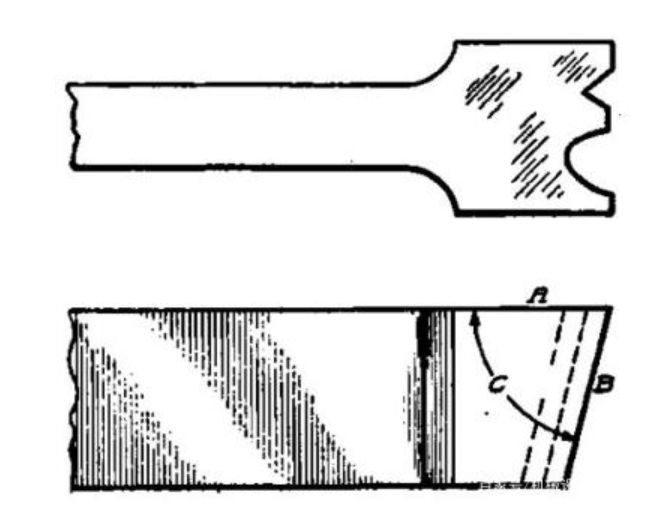

11. Zvishandiso zvekuchera

Maturusi ekuchera zvakare akakosha kwazvo maturusi mune lathes.Zvishandiso zvekuchera zvinonyanya kushandiswa kumichina cylindrical makomba mune yakapihwa workpiece.Muchiitiko ichi, workpiece inogadziriswa panhizha, iyo drill bit inogadziriswa mu tailstock drill frame, uye gomba rinofanira kupedzwa nekufamba kwe tailstock spindle.Izvi zvinoshanda kune anogara akaumbwa workpieces.

B) Zvinoenderana nekushandisa nzira yekudyisa:

Iwo akakamurwa kuva marudzi matatu:

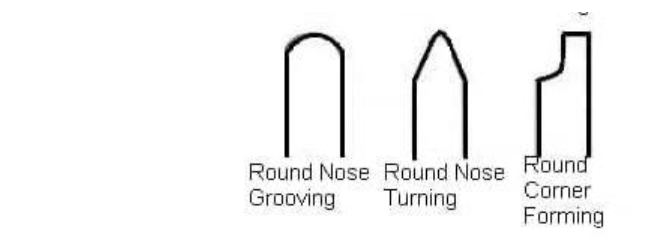

12. Round mhino mudziyo

Round mhuno yekucheka inogona kutsanangurwa sechishandiso chinoshandiswa pakupedzisa machining.Mapanga emhuno akatenderedzwa haana divi kana kumashure kwake uye anogona kucheka neimwe nzira.

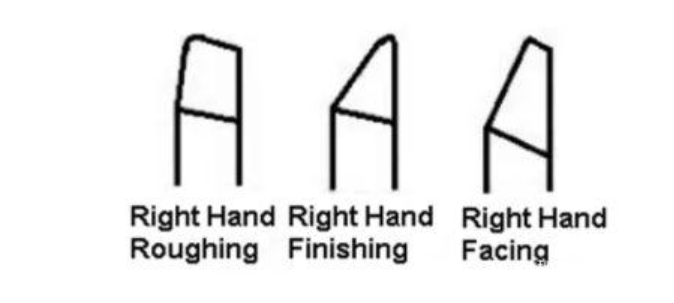

13. Chishandiso cheruoko rworudyi

Chishandiso chekurudyi chekushandura chinobvisa zvinhu sezvachinofamba kubva kurudyi chichienda kuruboshwe (chinongoda maonero epamusoro, kuchengetedza reki chiso pamusoro).Zita rechishandiso cheruoko rwerudyi rinoshandiswa zvichienderana nekufananidza kweruoko rwemunhu.Neruoko rwerudyi, chigunwe chinomiririra nzira yekudyisa mudziyo.Nokudaro, iyo huru yekucheka kwechigadziro chiri kuruboshwe rwechigadziro.

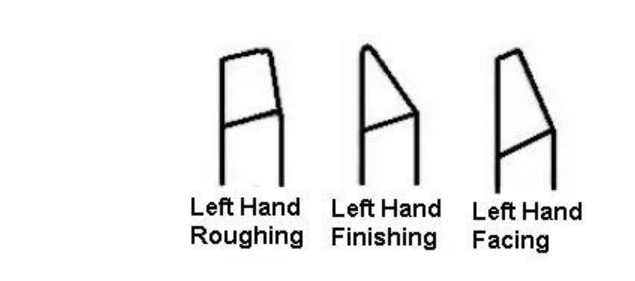

14. Zvishandiso zvekuruboshwe

Kusiyana nekurudyi-kutendeutsa maturusi, maturusi ekuruboshwe anobvisa zvinhu pavanenge vachifamba kubva kuruboshwe kuenda kurudyi (yepamusoro maonero anochengeta reki kumeso kuoneka).Neruoko rweruboshwe, chigunwe chinomiririra kwakananga kune chikafu chemidziyo.Nokudaro, iyo huru yekucheka kwechigadziro chiri kurutivi rworudyi rwechishandiso.

Nzira yekusarudza lathe tool

Kusarudza chishandiso chinoda kunzwisisa zvimwe zvinhu zvine chekuita nemidziyo.Izvi zvinotevera zvinhu zvakakosha zvaunofanira kufunga nezvazvo pakusarudza lathe:

rudzi rwezvinhu

Rudzi rwezvinhu zvaunocheka ndicho chinhu chakakosha pakuona rudzi rwechishandiso chaunogona kushandisa.Hunhu hwakakosha hwaunofanirwa kucherekedza usati wasarudza chishandiso chekushandura zvinosanganisira: kuoma, kusakara, kuoma uye kuoma.Izvi zvivakwa zvinoita basa rakakosha mumhando dzelathe zvishandiso zvaunogona kushandisa.Semuenzaniso, zvinhu zvakaoma zvakanyanya zvinoda carbide kana madhaimani maturusi.

chimiro chemudziyo

Chimiro chechishandiso chelathe zvakare chimwe chinhu chekufunga nezvacho pakusarudza.Nzvimbo yekucheka kumucheto inotarisawo nzira yekucheka yechishandiso (kurudyi-kuruboshwe, kuruboshwe-kuruboshwe, uye mhino dzakatenderera).

machined chimiro

Imwe neimwe mhando yechishandiso chelathe chakanyorwa pasi pechikamu chinogona kukonzera chimiro chakatarwa.Naizvozvo, iwe unofanirwa kubatanidza iyo yaunoda chimiro mune yaunoda kutendeuka chishandiso.Nekuda kwekuoma kweakawanda CNC zvigadzirwa zvemuchina, ungangoda kusarudza musanganiswa weakawanda lathe maturusi.

Nguva yekutumira: Kubvumbi-24-2022