Renewable Design for Slow Feeding Nc Wire Cut Machine - Swiss CNC Lathe Machine – FOREST

Renewable Design for Slow Feeding Nc Wire Cut Machine - Swiss CNC Lathe Machine – FOREST Detail:

Product Description

Our WEDM cutting machine is composed of a host computer, an electrical control system, a software part, and a cooling filter system. This equipment is used for electrical discharge machining for trajectory cutting of various complex molds and parts, and for processing various non-ferrous metals, tool steels, alloy steels and other materials.

WEDM cutting machine has high geometric accuracy and position accuracy, and has sufficient static, dynamic, and thermal stiffness and accuracy. The equipment has taper cutting, variable taper and special-shaped meshing cutting functions.

Machine design

“Pyramid”-shaped cross slide structure, “T”-shaped bed, box-type structure design, the machine tool has sufficient static and dynamic rigidity, reliable work, simple operation, convenient maintenance, and conforms to the principles of ergonomics.

The castings are all cast with resin sand technology, long-term natural aging, secondary tempering, complete internal stress elimination, which improves the rigidity and precision retention of the castings; increases the rigidity of the machine tool and reduces the amount of deformation; all the guide rails are made of bearing structural steel and quenched The hardness is between HRC56-60, which ensures the wear resistance of the guide rail.

The screw adopts a ball screw, which has high rolling precision and strong wear resistance. The workbench and the wire transport pallet are respectively rolled with precision balls, with low friction, stable movement and strong wear resistance.

The control cabinet is intuitive and convenient. There are multiple groups of modifiable parameter libraries. Users can flexibly save the cutting parameters of different materials, different heights, different speeds, and different surface roughness, as well as straightening and edge electrical parameters. This design reduces the need for machine tools. The operator’s requirements for process convenience, while simplifying and facilitating the operation of the machine tool.

Using a frequency converter, the speed of the wire conveying drum can be adjusted arbitrarily, thereby improving the smoothness of the workpiece, high efficiency (cutting efficiency can reach 7000 to 8000 square millimeters per hour), and can realize the function of cutting wire = knife cutting. Consumption 0.85 degrees) Compared with ordinary machine tools, it can save energy by 50% and is environmentally friendly (the machine tool’s environmental protection water cover prevents the working fluid from splashing. The working fluid can be replaced once every 30 working days with the high-pressure filter water tank, which greatly improves the working time and the number of sewage discharges.

| Power supply | AC 380V, 50HZ, 3 Phrase, customized |

| Stepping method | three-phase six-beat or five-phase ten-beat, pulse equivalent: 1um |

| Rated power | 3.5KW 1.0KW |

| Pulse power output voltage | 100V |

| Pulse Width (TON) | 2US-128US |

| Pulse interval (TOFF) | 2-9 times TON |

| Inverter gear | Processing “50 “wire up”10-30″ |

| Models | Working Table(mm) | Working Table travel(mm) | Max processing thickness(mm) | Max processing Taper (mm) | Processing Loading(KG) | Weight(KG) | Measure(L*W*H) |

| DK7720 | 420*270 | 250*200 | 300 | 0° | 100 | 900 | 1500*1000*1700 |

| DK7725 | 520*280 | 350*250 | 300 | 0° | 150 | 1200 | 1500*1050*1800 |

| DK7735 | 630*380 | 450*350 | 400 | 6°~45°/80mm | 250 | 1400 | 1700*1130*1800 |

| DK7745 | 850*580 | 450*550 | 400 | 6°~45°/80mm | 450 | 1700 | 1900*1300*1800 |

| DK7750 | 960*680 | 500*630 | 500 | 6°~45°/80mm | 500 | 2300 | 2100*1550*2000 |

| DK7763 | 1170*780 | 630*800 | 600 | 6°~45°/80mm | 950 | 2800 | 2250*1800*2300 |

| DK7780 | 1350*980 | 800*1000 | 800 | 6°~45°/80mm | 1000 | 5000 | 2400*2100*2300 |

| DK77100 | 1600*1150 | 1000*1200 | 1000 | 6°~45°/80mm | 1100 | 6000 | 2500*2300*2500 |

| DK77120 | 1900*1500 | 1200*1400 | 1000 | 6°~45°/80mm | 1800 | 7500 | 3800*3800*2700 |

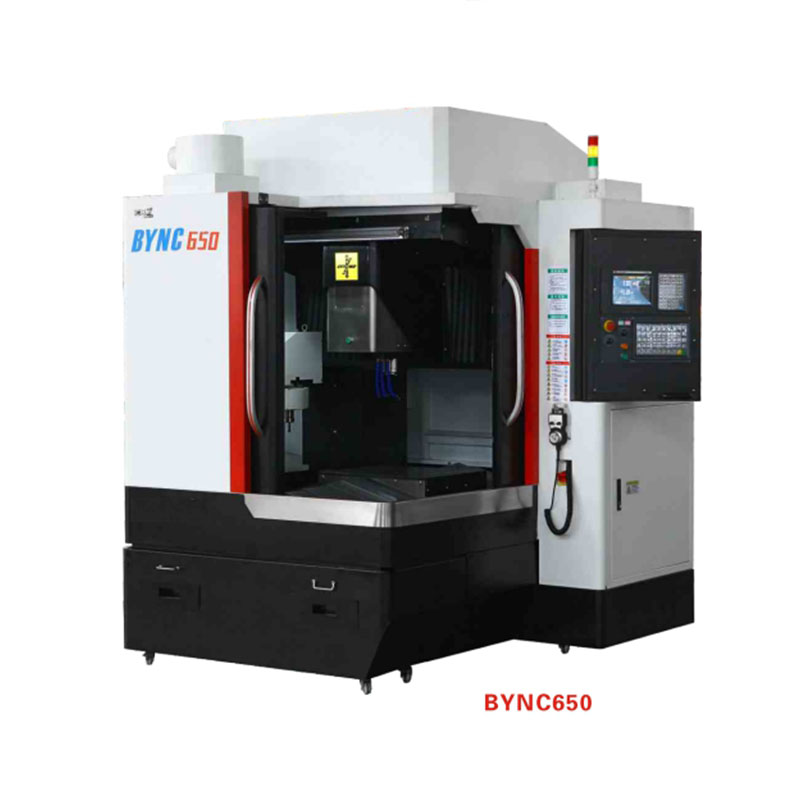

Product detail pictures:

Related Product Guide:

The organization keeps on the procedure concept scientific management, high quality and efficiency primacy, purchaser supreme for Renewable Design for Slow Feeding Nc Wire Cut Machine - Swiss CNC Lathe Machine – FOREST, The product will supply to all over the world, such as: Slovenia, United Kingdom, Tunisia, With strong technical strength and advanced production equipment, and SMS people purposefully , qualified, dedicated spirit of enterprise. Enterprises took the lead through the ISO 9001:2008 international quality management system certification, CE certification EU ; CCC.SGS.CQC other related product certification. We look forward to reactivating our company connection.

It is not easy to find such a professional and responsible provider in today's time. Hope that we can maintain long-term cooperation.