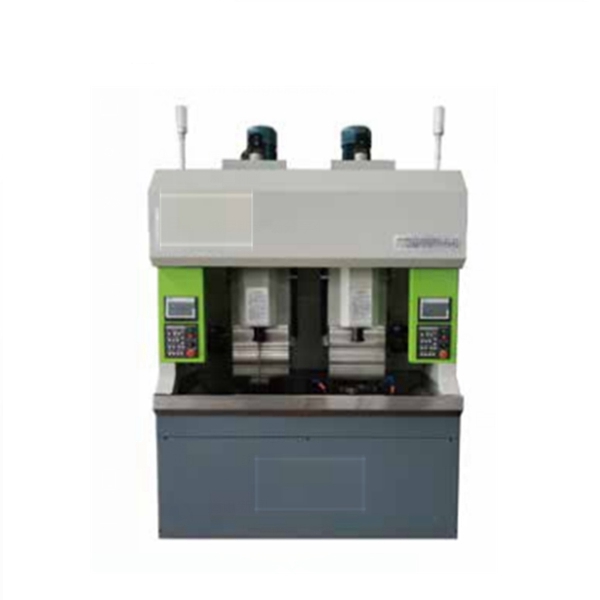

Quality Inspection for Honing Tools - Manual & auto surface grinding machine – FOREST

Quality Inspection for Honing Tools - Manual & auto surface grinding machine – FOREST Detail:

Product Description

The spindle of M250 manual surface grinding machine adopts P4 grade precision bearing, which has high reliability and convenient maintenance.

The machine tool adopts double V sticking plastic horizontally , one V and one flat longitudinal track , and ball steel track (adopt overall quenching ),which has high stability and accuracy, and easy and flexible operation . The movable parts are lubricated by hand-pulled oil lumps and equipped with various special accessories to meet the requirements of arc grinding and other complex forming.

M-250YHAS hydraulic automatic display surface grinding machine, the workbench for manual movement around hydraulic automatic system system before and after the main mechanical valve for grinding machine is special valve, divided into two parts , mechanical commutation control, throttle speed regulation control throttle control part and unloading function, which can realize the workbench of the rev. Stop this valve has buffer adjustment function of the machine tool is convent and flexible and reliable operation without vibration precision stability of thermal stability of low noise and easy maintenance.

| Models | M250 | M250AH | M250YH | M250YHAS | ||

| Working table(mm) | 500*250 | 500*250 | 500*230 | 500*250 | ||

| Max table travel(mm) | 550 | 550 | 550 | 550 | ||

| Max cross travel(mm) | 280 | 280 | 250 | 280 | ||

| Distance between table and Spindle center | 470 | 470 | 470 | 470 | ||

| Max table load(kg) | 100 | 100 | 300 | 300 | ||

| Tee slot(nos*width) | 14×1 | 14×1 | 14×1 | 14×1 | ||

| Table speed(m/min) | Manual | 0-25 | 5-25 | 5-25 | ||

| Crossfeed handwheel | 1 grade | 0.02 | 0.02 | 0.02 | 0.02 | |

| 1 rev | 2.5 | 2.5 | 2.5 | 2.5 | ||

| Auto crossfeet of saddle(mm) | — | 0.5-12 | 0.5-12 | 0.5-12 | ||

| Power cross feed | 50HZ | — | 750 | 750 | 750 | |

| 60HZ | — | 950 | 950 | 950 | ||

| Grinding wheel | 200*17*31.75/32 | 200*17*31.75/32 | 180*13*31.75/32 | 200*17*31.75/32 | ||

| Spindle speed | 50HZ | 2850 | 2850 | 2850 | 2850 | |

| 60HZ | 3420 | 3420 | 3420 | 3420 | ||

| Vertical handwheel | 1 grade | 0.01 | 0.01 | 0.01 | 0.01 | |

| 1 rev | 1.25 | 1.25 | 1.25 | 1.25 | ||

| Spindle Motor(kw) | 1.5 | 1.5 | 1.5 | 1.5 | ||

| Hydraulic motor(kw) | 0.75 | — | 0.75 | 0.75 | ||

| Dust collector motor(kw) | — | – | – | – | ||

| Coolant motor(w) | 40 | 40 | 40 | 40 | ||

| Crossfeed motor(w) | 60 | 60 | 60 | 60 | ||

| Floor Space(mm) | 2500*1500*1800 | 2500*1500*1800 | 2500*1500*1800 | 2500*1500*1800 | ||

| Net weight(KG) | 1000 | 1000 | 1000 | 1000 | ||

| Gross weight (KG) | 1100 | 1100 | 1100 | 1100 | ||

| Power supply | 380V, 3 phase, 50HZ/60HZ, customized | |||||

Product detail pictures:

Related Product Guide:

We rely upon strategic thinking, constant modernisation in all segments, technological advances and of course upon our employees that directly participate inside our success for Quality Inspection for Honing Tools - Manual & auto surface grinding machine – FOREST, The product will supply to all over the world, such as: Comoros, Belgium, Auckland, Strong infrastructure is the need of any organization. We are backed with a robust infrastructural facility that enables us to manufacture, store, quality check and dispatch our products worldwide. To maintain smooth work flow, we have sectioned our infrastructure into a number of departments. All these departments are functional with latest tools, modernized machines and equipment. Owing to which, we are able to accomplish voluminous production without compromising upon the quality.

The supplier abide the theory of quality the basic, trust the first and management the advanced so that they can ensure a reliable product quality and stable customers.