PriceList for Cnc Plate Drilling Machine - Hydraulic Radial Drilling Machine – FOREST

PriceList for Cnc Plate Drilling Machine - Hydraulic Radial Drilling Machine – FOREST Detail:

Product Description

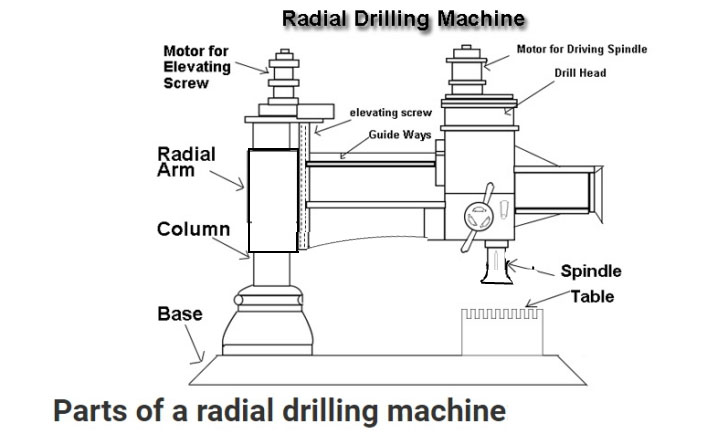

Hydraulic radial drilling machines are made of high-strength cast iron and steel. The strong structure are verified by many running in different fields, with complete safety protection devices to protect operators.

A hydraulic preselected variable speed mechanism of radial drilling machines saves auxiliary time.

Spindle of drill machine can turn clockwise and counterclockwise. The drill machine can stop, change speeds and neutral gear. A hand shift brings easy control.

Hydraulic radial drilling machines adopt driven hydraulically clamping mechanism of diamond block in spindle box,radial arm and columns. Which are convenient, reliable and stable. The 22-grade spindle speed and feed can achieve economical and efficient cutting ratio with optional parameter set.

Radial drilling machines use tempering treatment in guide ways, outer cylindrical surface, spindle, spindle sleeve and columns to achieve steady accuracy of machine in long service life time.

Parameter

| Items | Z3032 | Z3040 | Z3050 | Z3063 | Z3080 | Z30100 |

| Max drill diameter (mm) | Carbon Steel: 32 Cast Iron: 40 |

Carbon Steel: 40 Cast Iron: 50 | Carbon Steel: 50 Cast Iron: 68 | Carbon Steel: 63 Cast Iron: 80 | Carbon Steel: 80 Cast Iron: 95 | Carbon Steel: 100 Cast Iron: 110 |

| Distance from spindle center line to column bus bar(mm) | 350-1000 | 350-1250 | 260-1600 | 450-2000 | 480-2500 | 480-3150 |

| Distance from spindle end face to base working face(mm) | 260-1100 | 260-1250 | 350-1250 | 220-1400 | 350-1600 | 750-2500 |

| Spindle stroke(mm) | Manual: 300, machine: 280 | Manual: 300, machine: 280 | Manual: 315, machine: 315 | Manual: 400, machine: 400 | Manual: 410, machine: 400 | Manual: 500, machine: 500 |

| Spindle taper (Mohs) | 4# | 4# | 5# | 6# | 6# | 6# |

| Spindle speed (r/min) | 25-1600 | 25-2000 | 25-2000 | 16-1600 | 16-1600 | 8-1000 |

| Spindle speed grade | 12 | 16 | 16 | 16 | 16 | 16 |

| Feed of Spindle(mm/r) | 0.1-0.25 | 0.1-0.25 | 0.04-3.20 | 0.04-3.20 | 0.04-3.30 | 0.04-3.20 |

| Feed grade |

16 |

22 | ||||

| Working table(mm) |

500×630 |

630×800 | 800×1000 | 800×1250 | ||

| Horizontal movable distance of spindle box(mm) | 1000 | 1000 | 1600 | 2000 | 2500 | 2580 |

| Spindle motor power(KW) | 3 | 3 | 4 | 5.5 | 7.5 | 15 |

| Weight(KG) | 1500 | 1600 | 3500 | 6500 | 11800 | 20000 |

| Measure(mm LxWxH) | 1900x1070x2400(LxWxH) | 2150x1070x2400 | 2500x1070x2800 | 3000x1250x3300 | 3500x1450x3300 | 4780x1650x4720 |

| Working temperature |

Less than 75℃,avoid direct sunlight |

|||||

| Relative humidity |

40%~98% |

|||||

| Power supply |

AC 380V, 50 HZ, 3P(5 wires). Customized. |

|||||

|

Keep machine away from excessive dust and corrosive gases. Constant temperature workroom benefit long lifetime. |

||||||

Product detail pictures:

Related Product Guide:

Our concentrate on is always to consolidate and enhance the excellent and service of present solutions, in the meantime regularly develop new products to meet distinctive customers' demands for PriceList for Cnc Plate Drilling Machine - Hydraulic Radial Drilling Machine – FOREST, The product will supply to all over the world, such as: Macedonia, Madagascar, French, Based on our guiding principle of quality is the key to development, we continually strive to exceed our customers' expectations. As such, we sincerely invite all interested companies to contact us for future cooperation, We welcome old and new customers to hold hands together for exploring and developing; For more information, please feel free to contact us. Thanks. Advanced equipment, strict quality control, customer-orientation service, initiative summary and improvement of defects and extensive industry experience enable us to guarantee more customer satisfaction and reputation which, in return, brings us more orders and benefits. If you are interested in any of our products, please feel free to contact us. Inquiry or visit to our company are warmly welcome. We sincerely hope to start a win-win and friendly partnership with you. You can see more details in our website.

This manufacturers not only respected our choice and requirements, but also gave us a lot of good suggestions, ultimately, we successfully completed the procurement tasks.