OEM/ODM Supplier Bench Drill Milling Machine - Gantry CNC drilling machine – FOREST

OEM/ODM Supplier Bench Drill Milling Machine - Gantry CNC drilling machine – FOREST Detail:

Product Description

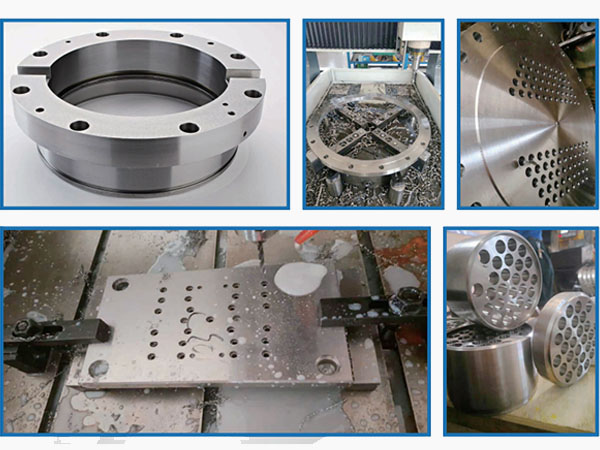

Gantry CNC drilling machine has drilling, countersinking, chamfering, tapping and light milling functions, it is widely used in rectangular tubes, plates, and structural parts processing.

Ordinary radial drill need one operator could make scribing, drilling and processing of pilot holes. Operator have much work to do, and man cant work all time. The finishing or workpieces are decided by operators’ operation and experience. And this type working cant suit mass production. So CNC drilling machines can solve above problems and bring high efficient. One worker would operate several CNC drilling machines at one time. CNC drilling machines keep continuous working, increase output efficiency, have low safety hazards, high workpiece precision and good consistency.

The machine tool is mainly composed of body, worktable, gantry, power head, numerical control system, cooling system and other parts.

Parameter

| Items | Model F-LK-1010 | Model F-LK-1020 | Model F-LK-1620 | Model F-LK-2020 |

| LxW (mm) | 1000X1000 | 2000X1000 | 2000×1600 | 2000×2000 |

| Maxi thickness of workpiece(mm) | 220 | 400 | 400 | 300 |

| Spindle boring | BT40 | BT40 | BT40 | BT40 |

| Drill diameter (mm) | Φ1-φ36 | Φ3-φ36 | Φ3-φ36 | Φ3-φ40 |

| Tapping diameter (mm) | M3-M26 | M6-M26 | M6-M26 | M4-M26 |

| Spindle servo motor (KW) | 7.5 | 18.5 | 18.5 | 22 |

| Torque (N.m) | 100 | 100 | 100 | 282.6 |

| Distance between spindle nose and working table(mm) | 200-600 | 460-830 | 200-600 | 300-900 |

| X axis maxi travel(mm) | 1000 | 1000 | 1500 | 2000 |

| X axis move speed(m/min) | 0-9 | 0-8 | 0-8 | 0-8 |

| X axis servo motor power (KW) | 2.4*1(15N.m) | 2.4 | 2.4 | 2.4*2 |

| Y axis maxi travel(mm) | 1000 | 2000 | 2000 | 2000 |

| Y axis move speed(m/min) | 0-9 | 0-8 | 0-8 | 0-8 |

| Y axis servo motor power (KW) | 2.4*1(15N.m) | 2.4*2 | 2.4*2 | 2.4*1 |

| Z axis maxi travel(mm) | 370 | 370 | 370 | 600 |

| Z axis move speed(m/min) | 0-8 | 0-4 | 0-4 | 0-4 |

| L*W*H(mm) | 2500*1560*2200 | 3800*2400*2300 | 2800*2400*2300 | 5600*4600*3350 |

| Gross Weight(KG) | 4600 | 7600 | 9500 | 20000 |

| Items | Model F-LK-3016 | Model F-LK- 3020 |

Model F-LK- 3030 |

Model F-LK- 3060 |

| LxW (mm) | 3000×1600 | 3000×2000 | 3000×3000 | 3000×6000 |

| Maxi thickness of workpiece(mm) | 200 | 200 | 200 | 500 |

| Spindle boring | BT50 | BT50 | BT50 | BT50 |

| Drill diameter (mm) | Φ3-φ50 | Φ3-φ80 | φ50 | Φ5-φ60 |

| Tapping diameter (mm) | M6-M36 | M4-M36 | M36 | M36 |

| Spindle servo motor (KW) | 7.5 | 30 | 11 | 22 |

| Torque (N.m) | 292.6 | 400 | 200(when n<250r/min) | 200(when n<250r/min) |

| Distance between spindle nose and working table(mm) | 260-630/460-830 | 350-800 | 280-780 | 280-780 |

| X axis maxi travel(mm) | 1600 | 2000 | 3000 | 3000 |

| X axis move speed(m/min) | 0-8 | 0-8 | 0-8 | 0-8 |

| X axis servo motor power (KW) | 2.4 | 2.4*2(15N.m) | 2*3KW/( 28.4N.m) | 1*2.4KW/( 15N.m) |

| Y axis maxi travel(mm) | 3000 | 3000 | 3000 | 6000 |

| Y axis move speed(m/min) | 0-8 | 0-8 | 0-8 | 0-8 |

| Y axis servo motor power (KW) | 2.4*2 | 2.4*1(15N.m) | 2*2.4KW/(15N.m) | 2*2.4KW/(15N.m) |

| Z axis maxi travel(mm) | 370 | 450 | 500 | 500 |

| Z axis move speed(m/min) | 0-4 | 0-4 | 0-5 | 0-5 |

| L*W*H(mm) | 4700*3000*2300 | 6600*4600*3350 | 6200*5200*3600 | 8200*4800*3000 |

| Gross Weight(KG) | 21000 | 23000 | 26000 | 35 |

Product detail pictures:

Related Product Guide:

Our products and solutions are greatly recognized and trustworthy by customers and may fulfill constantly changing financial and social requires for OEM/ODM Supplier Bench Drill Milling Machine - Gantry CNC drilling machine – FOREST, The product will supply to all over the world, such as: azerbaijan, London, London, We have a dedicated and aggressive sales team, and many branches, catering to our customers. We are looking for long-term business partnerships, and ensure our suppliers that they will definitely benefit in both short and long run.

Perfect services, quality products and competitive prices, we have work many times, every time is delighted, wish continue to maintain!