OEM/ODM Factory Honing Guide Sled - Good Prices Simple Vertical Honing Machines – FOREST

OEM/ODM Factory Honing Guide Sled - Good Prices Simple Vertical Honing Machines – FOREST Detail:

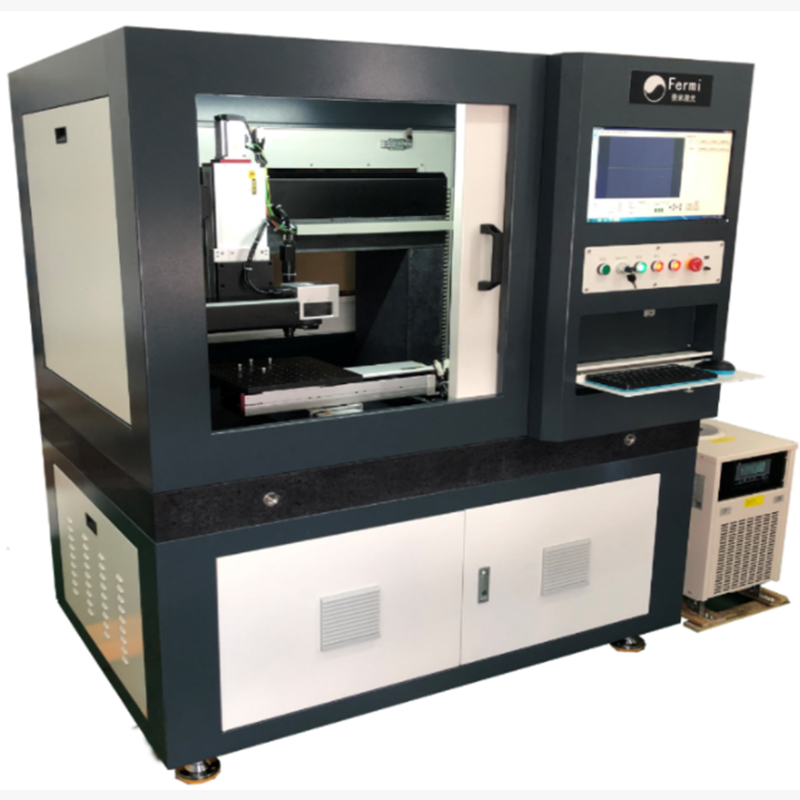

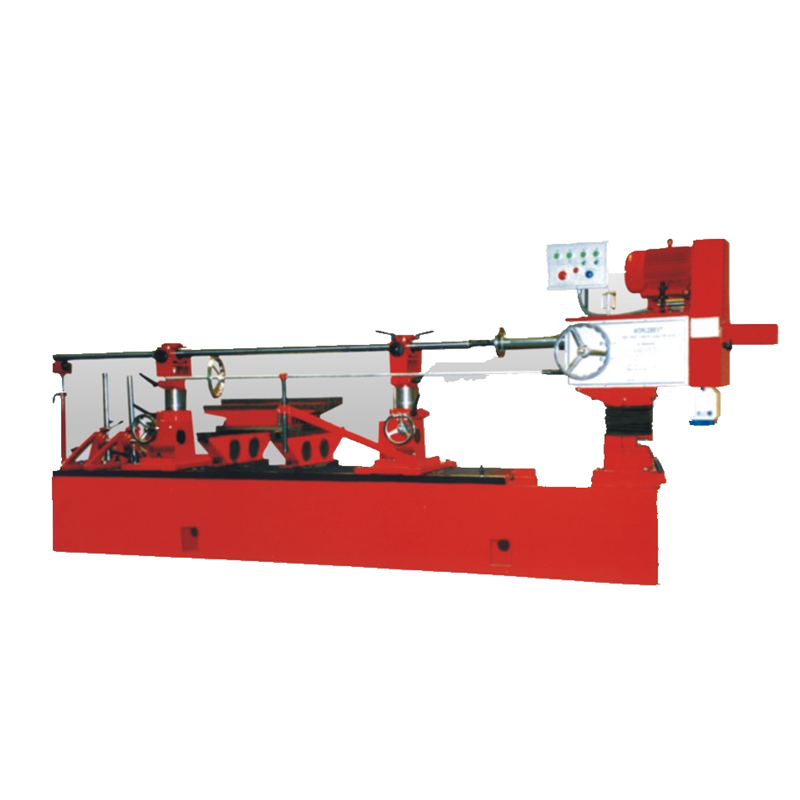

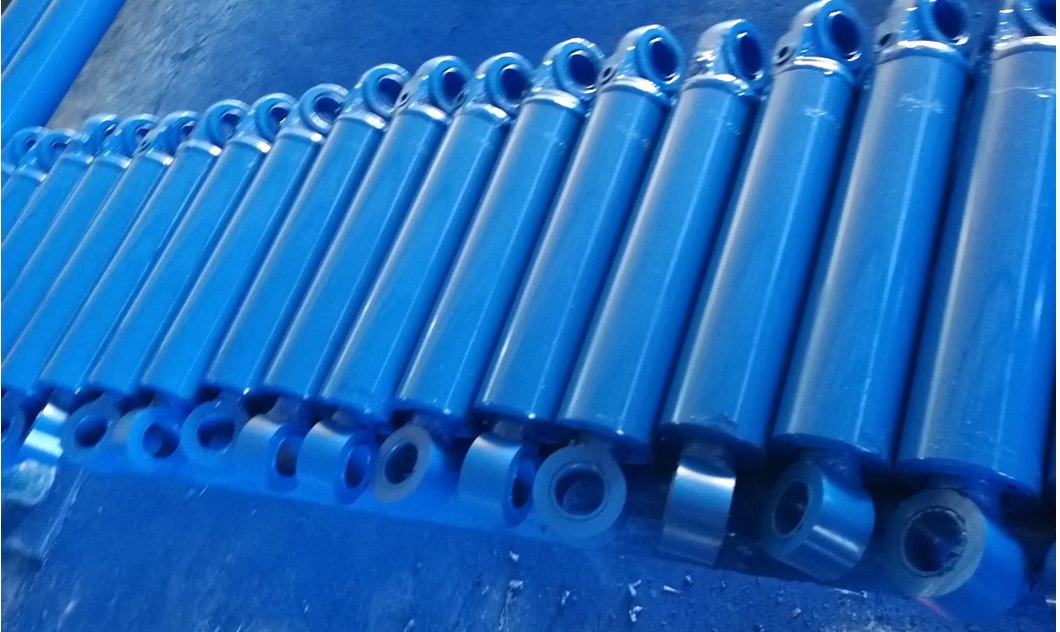

This machine tool is suitable for processing various engine cylinder holes, cylinder casing holes, hydraulic valve body holes, piston ring holes and other precise through holes and non-through holes. The parts processed by this machine tool can be either cast iron or steel, including heat treatment machine parts. The workbench is controlled by the motor to move left and right. The workbench has high positioning accuracy and can be positioned at any point within the travel range. Equipped with a two-stage filter constant temperature cooling system for magnetic roll paper tape. With automatic online measurement function It has the function of double feed, that is, it can realize the honing of platform texture or the rough honing and fine honing of work on one grinding head, which improves the honing effect

Technical Parameters

| NO | Items | Description | ||

| 1 | Model | LHCA 10×32 | LHSCA 18×50-Y | LHCC 20×40 |

| 2 | Maxi diameter | Φ100mm | Φ180mm | Φ200mm |

| 3 | Mini diameter | Φ10mm | Φ12mm | Φ50mm |

| 4 | Maxi stroke length | 320mm | 650mm | 550mm |

| 5 | Distance between spindle end to worktable | 880mm | 1700mm | 1520mm |

| 6 | Spindle center to column | 200mm | 350mm | 350mm |

| 7 | Stroke speed | 3-18 m/min | 3-28 m/min | 3-28 m/min |

| 8 | Spindle rotation speed | stepless adjustment | 50-300rpm stepless adjustment | 60-400rpm stepless adjustment |

| 9 | Worktable stroke | / | 750mm | Maxi to 800mm |

| 10 | Worktable size | 600*600mm | 1250*500mm | 1250*500mm |

| 11 | Worktable height | 600mm | 600mm | 600mm |

| 12 | Spindle motor | 3 KW | 7.5 KW | 7.5 KW |

| 13 | Hydraulic motor power | 4 KW | 7.5 KW | 7.5 KW |

| 14 | Measure | 1600*2370*3000mm | 1460*1390*4133mm | 1390*1400*3300 |

| 15 | Notes | Worktable could be movable or fixed | ||

| 16 | Power supply | 380V, 50HZ, 3phase | 380V, 50HZ, 3phase |

| NO | Items | Description | ||

| 1 | Model | LHCD 40×120 | LHCB 20×100 | LHCD 90×120 |

| 2 | Maxi diameter | Φ400mm | Φ200mm | Φ900mm |

| 3 | Mini diameter | Φ80mm | Φ40mm | Φ80mm |

| 4 | Maxi stroke length | 1200mm | 1150mm | 1500mm |

| 5 | Distance between spindle end to worktable | 3480mm | 2603mm | 3480mm |

| 6 | Spindle center to column | 450mm | 370mm | 800mm |

| 7 | Stroke speed | 5-18 m/min | 3-30 m/min | 5-18 m/min |

| 8 | Spindle rotation speed | 30-150 rpm | 50-80 rpm | 30-150rpm |

| 9 | Worktable stroke | Maxi to 800mm | 500mm | Maxi to 1000mm |

| 10 | Worktable size | 1600*700mm | 500*1250mm | 3500*1400mm |

| 11 | Worktable height | 600mm | 450mm | 600mm |

| 12 | Spindle motor | 15 KW | 7.5 KW | 22 KW |

| 13 | Hydraulic motor power | 11 KW | 7.5 KW | 11 KW |

| 14 | Measure | 2000*1980*5400mm | 1520*1950*4830mm | 3400*2800*5400 |

| 15 | Notes | Worktable could be movable or fixed | ||

| 16 | Power supply | 380V, 50HZ, 3phase | 380V, 50HZ, 3phase | 380V, 50HZ, 3phase |

More machine to contact with us.

Product detail pictures:

Related Product Guide:

We'll make every effort and hard work being outstanding and excellent, and speed up our techniques for standing during the rank of global top-grade and high-tech enterprises for OEM/ODM Factory Honing Guide Sled - Good Prices Simple Vertical Honing Machines – FOREST, The product will supply to all over the world, such as: Ireland, Cairo, French, Good quality, Good service is always our tenet and credo. We take every effort to control the quality, package, labels etc and our QC will check every detail during producing and before shipment. We have been willing to establish long business relationship with all those who seek the high quality products and good service. We've got set up a wide sales network across European countries, North of America, South of America, Middle East, Africa, East Asia countries.Please contact us now, you will find our expert experience and high quality grades will contribute to your business.

This company can be well to meet our needs on product quantity and delivery time, so we always choose them when we have procurement requirements.