The cutters of lathes are steel, CBN (cubic boron nitride), Ceramic, diamond and etc.

Types of lathe Cutting Tools:

Depending on the application, lathe cutting tools are basically divided into two types:

A) According to how the tool is used.

B) Method of feeding according to application

A) Depending on how the tool is used:

There are 11 types of knives:

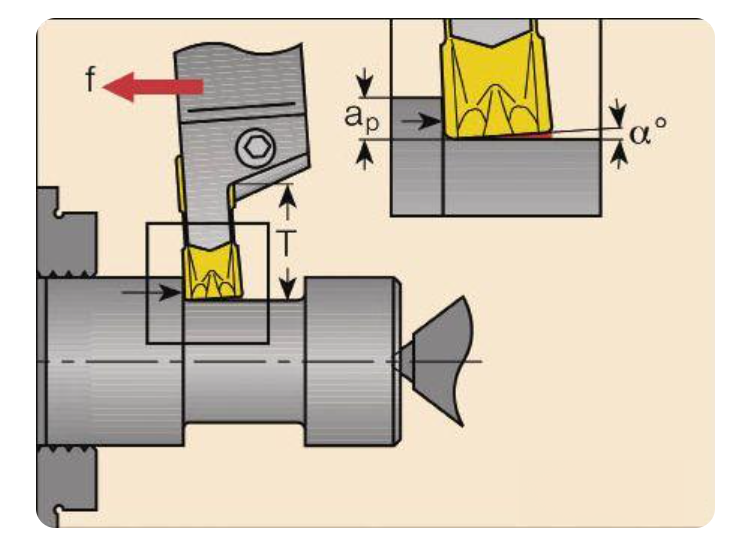

1. Thread cutting tools

They are of two types:

Externally Threaded Tools – Externally threaded tools are also known as threading tools. They are defined as tools for machining external threads of workpieces.

Internal thread tool—An internal thread tool is defined as a tool used to machine internal threads in a workpiece.

2. Chamfering tool

A chamfering tool can be defined as a tool used to design bevels or grooves on bolts. These tools are used to chamfer the corners of workpieces. When a large amount of chamfering is required, a specific chamfering tool with side chamfers is required.

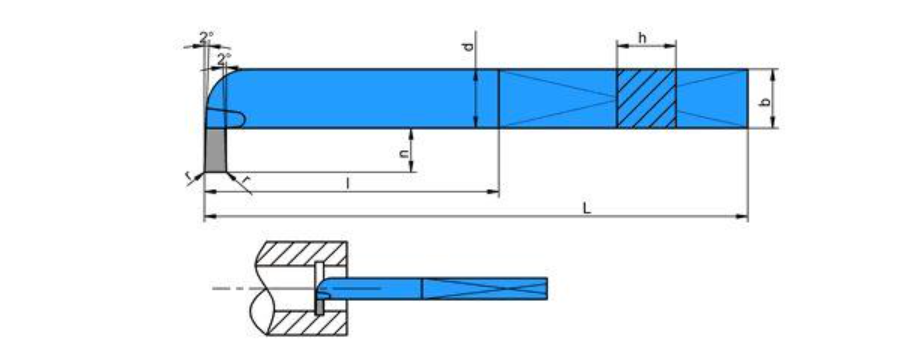

3. Turning tools

There are generally two types of turning tools:

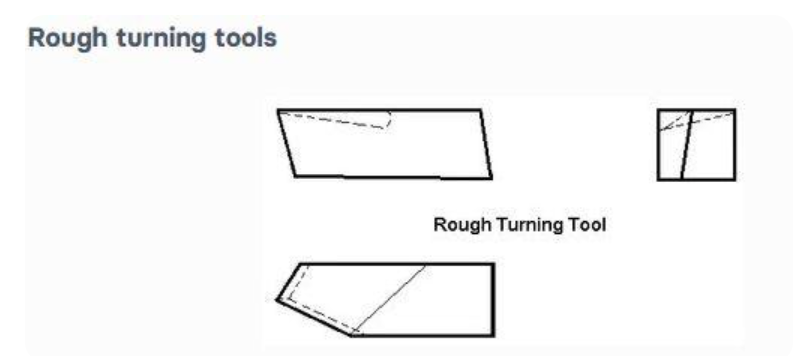

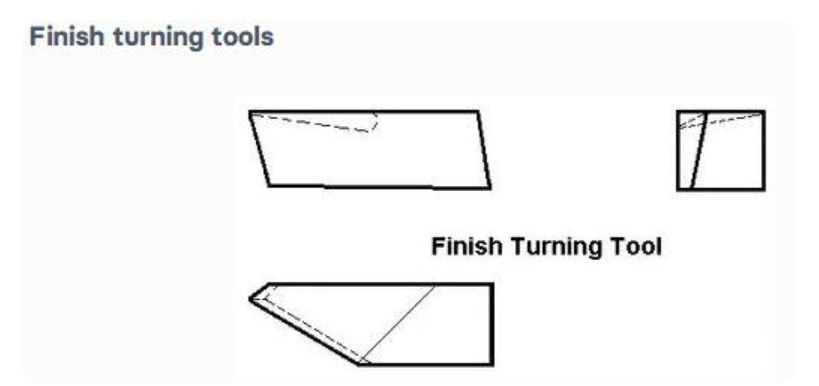

Rough Turning Tools – Rough turning tools are used to remove large amounts of metal in the shortest amount of time. And the cutting angle is clear and can withstand the maximum cutting force.

Fine Turning Knives – Fine turning tools are used to remove small amounts of metal. The cutting angle is also ground to produce a very smooth and precise surface

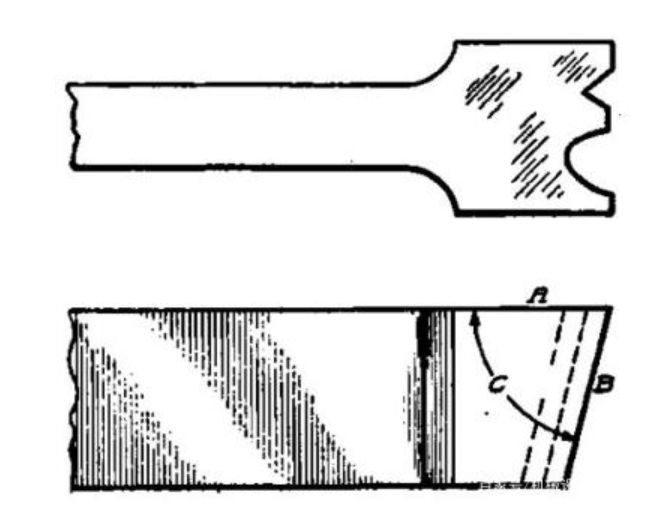

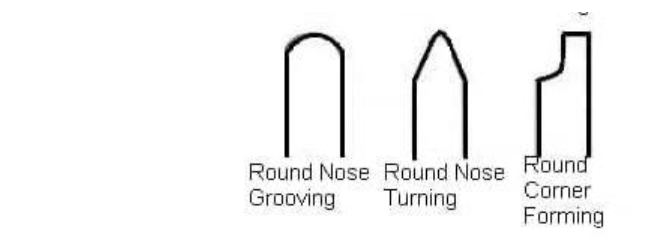

4. Slotting tool

Grooving tools are basically defined as tools used to create a narrow cavity of a certain depth in a cone, cylinder or surface of a part. In this case, the specific shape of the grooving tool is to be selected according to whether the grooves for edge cutting are square, round, etc.

5. End face cutter

A face tool can be defined as a tool used to cut a plane perpendicular to the axis of rotation of the workpiece. The face tool is carried by a tool holder fixed to the machine carrier. It is used to reduce the length of the workpiece by providing it perpendicular to the axis of the lathe. The cutting edge of the tool should be set at the same height as the center of the workpiece.

6. Boring tool

Boring is a lathe tool used to enlarge holes. When you want to enlarge an existing hole, you need to use a boring bar. Boring bars can easily be drilled into already drilled holes and enlarged in diameter. Can be quickly reamed to size for proper installation of other components.

7. Forming tool

Forming tools can be defined as tools used to create different types of workpiece shapes. In this case, a special type of cover or holder is used to hold the forming tool. From this we do various types of operations, such as making inner radius, outer radius, etc.

8. Counter boring tool

A back boring tool can be defined as a tool used to enlarge and locate the socket head of a screw or bolt. This tool has two radii:

A) Create pre-drilled holes

B) Drill holes in the workpiece

9. Reaming tool

A reaming tool is defined as a tool used for finishing and dimensional tolerance of drilled or drilled holes.

10. Undercutting tool

Undercutting tools are similar to grooving tools. In this case, an undercut tool is used to bore large holes at a fixed distance from the end of the hole. Undercutting is primarily done on the inner thread for clearance.

11. Drilling tools

Drilling tools are also very important tools in lathes. Drilling tools are mainly used to machine cylindrical holes in a given workpiece. In this case, the workpiece is fixed on the panel, the drill bit is fixed in the tailstock drill frame, and the hole should be completed by the movement of the tailstock spindle. This applies to regularly shaped workpieces.

B) According to the application feed method:

They are divided into three types:

12. Round nose tool

Round nose cutting can be defined as a tool used for finishing machining. Round nose knives have no side or back rake and can cut in other directions.

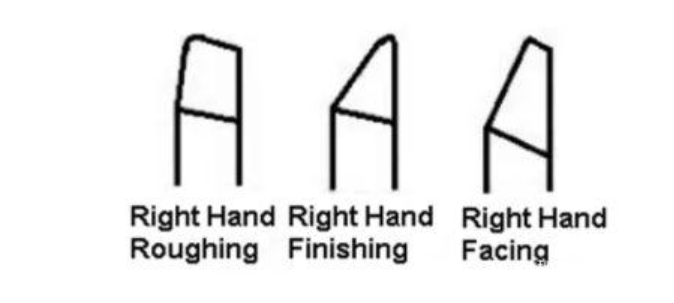

13. Right hand tool

A right-hand turning tool removes material as it moves from right to left (it only needs a top view, keeping the rake face on top). The name of the right hand tool is used based on the analogy of the human hand. With the right hand, the thumb represents the tool feed direction. Therefore, the main cutting edge of the tool is on the left side of the tool.

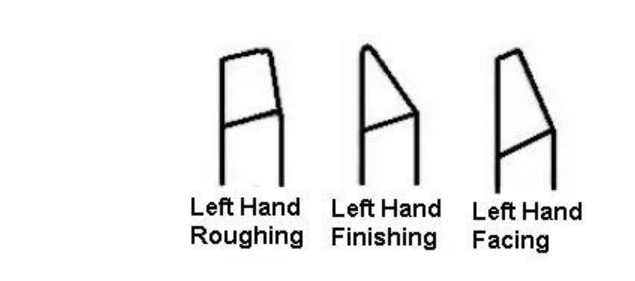

14. Left-handed tools

Unlike right-hand turning tools, left-hand tools remove material as they move from left to right (top view keeps the rake face visible). With the left hand, the thumb represents the direction of tool feed. Therefore, the main cutting edge of the tool is on the right side of the tool.

How to choose a lathe tool

Choosing a lathe tool requires understanding certain factors related to the equipment. The following are very important factors that you must consider when choosing a lathe:

type of material

The type of material you cut is a fundamental factor in determining the type of lathe tool you can use. Important attributes you must pay attention to before choosing a turning tool include: hardness, wear resistance, toughness and stiffness. These properties play an important role in the types of lathe tools you can use. For example, extremely hard materials require carbide or diamond tools.

shape of tool

The shape of the lathe tool is also another factor to consider when choosing. The position of the cutting edge also determines the cutting direction of the tool (right-hand, left-hand, and round nose).

machined shape

Each type of lathe tool listed under classification can result in the specified shape. Therefore, you must integrate the desired shape into the desired turning tool. Due to the complexity of most CNC machined products, you may need to choose a combination of several lathe tools.

Post time: Apr-24-2022