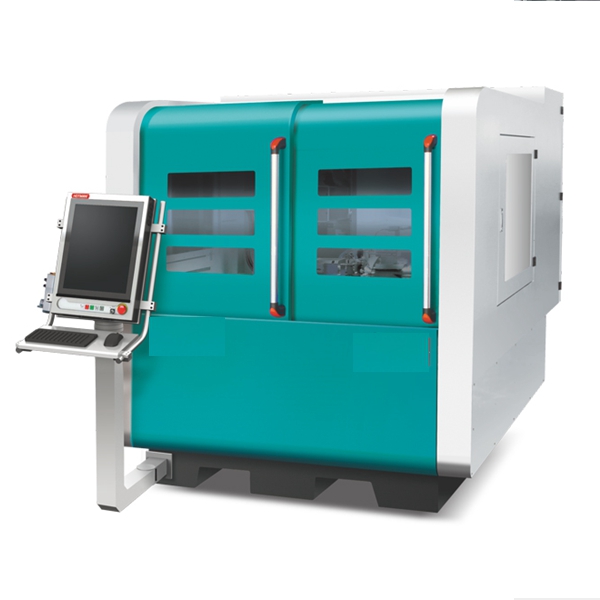

Massive Selection for Single Spindle Horizontal Boring Machine - High Precision Engine Vertical Boring Machine for repairing – FOREST

Massive Selection for Single Spindle Horizontal Boring Machine - High Precision Engine Vertical Boring Machine for repairing – FOREST Detail:

Product Description

This vertical boring machine is designed for engines holes, could boring and repair engines.

The strong cast iron base support machine running and workpieces. The spindle have a stroke in vertical, so that can boring to deep holes of workpieces.

We have boring cutters to boring a big range of holes. The vertical side is the guide of spindle travel.

There is a big working table to hold workpieces, if you need special fixture for special shapes , we also can design for you. The working table can move in vertical or horizontal. This design could help workpiece moving with handwheels.

The vertical precision boring machine is used for precision boring and processing of cylinder body holes and cylinder liner holes of various engines, as well as other precision holes. At the same time, it can be used for precision milling of cylinder end faces, which can realize multifunctional processing of boring, milling, drilling and reaming.

The structure of the vertical fine boring machine includes: vertical and horizontal movement mechanism of the worktable; quick centering mechanism of the workpiece; tool measuring device; longitudinal work advance (milling) of the workbench; Standard boring use.

We also supply the boring cutters for different material and diameters.

Parameter

| Items | Model: F-T716A | Model: F-T720 |

| Boring Diameter Range(mm) | Φ21-Φ165 | Φ21-Φ200 |

| Boring Maxi depth(mm) | 410 | 410 |

| Maxi slide movement (mm) | 560 | 710 |

| Working table (mm) | 1200×500(L*W) | 1200×500(L*W) |

| Maxi vertical movement of working table (mm) | 700 | 900 |

| Maxi horizontal movement of working table (mm) | no | 100 |

| Feeding per rotation of spindle(mm/r) | 0.05-0.2(4 grades) | 0.05-0.2(4 grades) |

| Spindle speed(r/min) | 190-600(6 grades) | 70~800(8 grades) |

| Spindle motor power(KW) | 2.2 | 1.5/2.4 |

| Boring tools | Buy separately | |

| Measure(mm): (L*W*H) | 1845x1712x2225 | 2000x1610x2422 |

| Power supply | 380V, 50HZ, 3Phase, or customized | |

| After-selling service | English manual, video support, one year warranty | |

| Items | Model: F-T7228 | Model: F-T7240D |

| Boring Diameter Range(mm) | Φ35-Φ280 | Φ51-Φ400 |

| Boring Maxi depth(mm) | 650 | 750 |

| Maxi slide movement (mm) | 560 | 710 |

| Working table (mm) | 1200×500(L*W) | 1200×500(L*W) |

| Maxi vertical movement of working table (mm) | 700 | 900 |

| Maxi horizontal movement of working table (mm) | no | 100 |

| Feeding per rotation of spindle(mm/r) | 0.05-0.2(4 grades) | 0.05-0.2(4 grades) |

| Spindle speed(r/min) | 190-600(6 grades) | 70~800(8 grades) |

| Spindle motor power(KW) | 2.2 | 1.5/2.4 |

| Power supply | 380V, 50HZ, 3Phase, or customized | |

| Measure(mm): (L*W*H) | 1845x1712x2225 | 2000x1610x2422 |

Product detail pictures:

Related Product Guide:

With our superb management, potent technical capability and strict quality command procedure, we go on to provide our shoppers with trustworthy high-quality, reasonable costs and outstanding services. We goal at becoming considered one of your most trustworthy partners and earning your pleasure for Massive Selection for Single Spindle Horizontal Boring Machine - High Precision Engine Vertical Boring Machine for repairing – FOREST, The product will supply to all over the world, such as: Barbados, Luxemburg, Mexico, Being guided by customer demands, aiming at improving the efficiency and quality of customer service, we constantly improve products and provide more comprehensive services. We sincerely welcome friends to negotiate business and start cooperation with us. We hope to join hands with friends in different industries to create a brilliant future.

This is a reputable company, they have a high level of business management, good quality product and service, every cooperation is assured and delighted!