Manufacturing Companies for Console Boring Machine - Cylinder body bushing boring machine – FOREST

Manufacturing Companies for Console Boring Machine - Cylinder body bushing boring machine – FOREST Detail:

Product Description

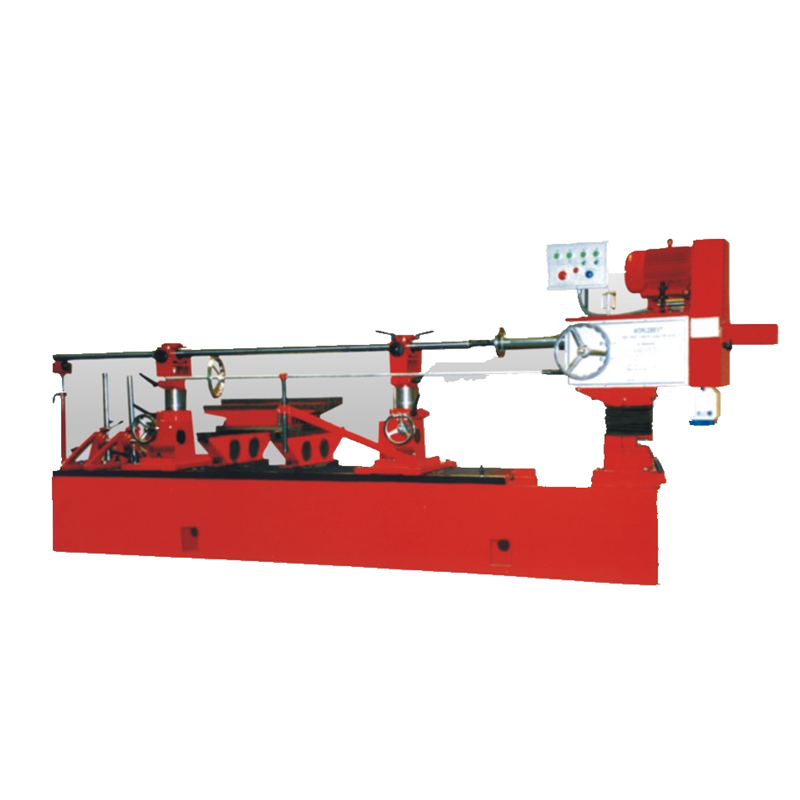

This cylinder bushing boring machine is a special boring machine for cylinders, the main bearing and camshaft bearing boring. This cylinder boring use strong cast iron base, there are two supports for boring bar, hold the boring bar straight and strong in boring processing. There is a handwheel helping operator feeding. This structure is better for repairing workshops, could get good finishing in roundness and cylinder.

This boring machine suits main bearing and camshaft bearing of engines and generator cylinder blocks of automobiles, tractors, ships, etc.

This boring machine also can boring flywheel housing holes and bearing socket holes of engines.

In order to reduce the lanor intensity of the operators shorten the auxiliary time and ensure the processing quality, the machine tools are equipped with a centering tool setting and inner diameter measuring table, as well as a boring bar bracket, an enlarged cutter head, a boring tool fine-tuning device and a remote tool setting device, etc.

Features

1. Boring tools have big strokes, could raise processing efficiency and Concentricity of cylinders.

2. Boring bars adopt special heat treatment to make boring bars harder and rigidity. With support holders and boring cutters, The boring machine could achieve good processing accuracy.

3. Boring heads use stepless adjustment, could process different inner bore diameters and materials of cylinders.

| Items | Model F-T8120Dx20 | Model F-T8125Ex25 |

| Diameter range(mm) | ID36-200 | ID36-200 |

| Max processing length (mm) | 2000mm | 2500mm |

| Max elongation of spindle (mm) | 300 | 300 |

| Spindle speed(rpm) | Frequency stepless speed 200-960 | Frequency stepless speed 200-960 |

| Feeding per rotation of spindle | Stepless 0~180mm/min | Stepless 0~180mm/min |

| Distanc between spindle axis and bed surface of machine(mm) | 570-870 | 570-870 |

| Motor (kw) | (Frequency conversion motor )1.5 | (Frequency conversion motor )1.5 |

| Boring tools | Based on workpieces, Buy separately | |

| Power supply | 380V, 50HZ, 3Phase /customized | |

| Measure(mm) L*W*H | 3910x650x1410 | 4410x650x1410 |

| Weight(KG) | 2300 | 2400 |

| Package | Wooden box | |

| After-selling service | Video support, one year warranty | |

Product detail pictures:

Related Product Guide:

We are proud of the high customer satisfaction and wide acceptance due to our persistent pursuit of high quality both on product and service for Manufacturing Companies for Console Boring Machine - Cylinder body bushing boring machine – FOREST, The product will supply to all over the world, such as: Lisbon, Paraguay, Tanzania, Our company offers the full range from pre-sales to after-sales service, from product development to audit the use of maintenance, based on strong technical strength, superior product performance, reasonable prices and perfect service, we'll continue to develop, to deliver the high-quality items and services, and promote lasting cooperation with our customers, common development and create a better future.

Sales manager is very enthusiastic and professional, gave us a great concessions and product quality is very good,thank you very much!