Manufacturer for Cnc Drilling Machine - Gantry CNC drilling machine – FOREST

Manufacturer for Cnc Drilling Machine - Gantry CNC drilling machine – FOREST Detail:

Product Description

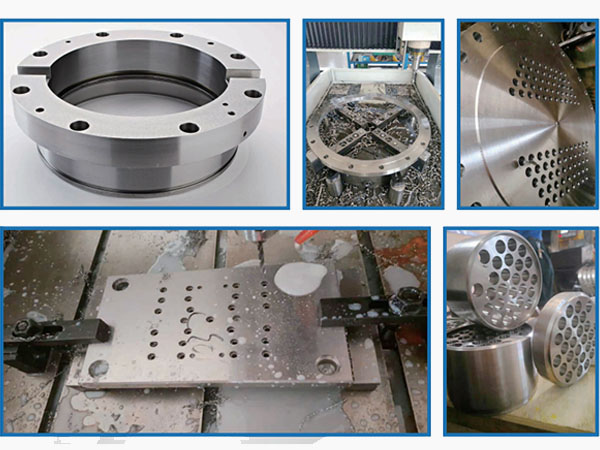

Gantry CNC drilling machine has drilling, countersinking, chamfering, tapping and light milling functions, it is widely used in rectangular tubes, plates, and structural parts processing.

Ordinary radial drill need one operator could make scribing, drilling and processing of pilot holes. Operator have much work to do, and man cant work all time. The finishing or workpieces are decided by operators’ operation and experience. And this type working cant suit mass production. So CNC drilling machines can solve above problems and bring high efficient. One worker would operate several CNC drilling machines at one time. CNC drilling machines keep continuous working, increase output efficiency, have low safety hazards, high workpiece precision and good consistency.

The machine tool is mainly composed of body, worktable, gantry, power head, numerical control system, cooling system and other parts.

Parameter

| Items | Model F-LK-1010 | Model F-LK-1020 | Model F-LK-1620 | Model F-LK-2020 |

| LxW (mm) | 1000X1000 | 2000X1000 | 2000×1600 | 2000×2000 |

| Maxi thickness of workpiece(mm) | 220 | 400 | 400 | 300 |

| Spindle boring | BT40 | BT40 | BT40 | BT40 |

| Drill diameter (mm) | Φ1-φ36 | Φ3-φ36 | Φ3-φ36 | Φ3-φ40 |

| Tapping diameter (mm) | M3-M26 | M6-M26 | M6-M26 | M4-M26 |

| Spindle servo motor (KW) | 7.5 | 18.5 | 18.5 | 22 |

| Torque (N.m) | 100 | 100 | 100 | 282.6 |

| Distance between spindle nose and working table(mm) | 200-600 | 460-830 | 200-600 | 300-900 |

| X axis maxi travel(mm) | 1000 | 1000 | 1500 | 2000 |

| X axis move speed(m/min) | 0-9 | 0-8 | 0-8 | 0-8 |

| X axis servo motor power (KW) | 2.4*1(15N.m) | 2.4 | 2.4 | 2.4*2 |

| Y axis maxi travel(mm) | 1000 | 2000 | 2000 | 2000 |

| Y axis move speed(m/min) | 0-9 | 0-8 | 0-8 | 0-8 |

| Y axis servo motor power (KW) | 2.4*1(15N.m) | 2.4*2 | 2.4*2 | 2.4*1 |

| Z axis maxi travel(mm) | 370 | 370 | 370 | 600 |

| Z axis move speed(m/min) | 0-8 | 0-4 | 0-4 | 0-4 |

| L*W*H(mm) | 2500*1560*2200 | 3800*2400*2300 | 2800*2400*2300 | 5600*4600*3350 |

| Gross Weight(KG) | 4600 | 7600 | 9500 | 20000 |

| Items | Model F-LK-3016 | Model F-LK- 3020 |

Model F-LK- 3030 |

Model F-LK- 3060 |

| LxW (mm) | 3000×1600 | 3000×2000 | 3000×3000 | 3000×6000 |

| Maxi thickness of workpiece(mm) | 200 | 200 | 200 | 500 |

| Spindle boring | BT50 | BT50 | BT50 | BT50 |

| Drill diameter (mm) | Φ3-φ50 | Φ3-φ80 | φ50 | Φ5-φ60 |

| Tapping diameter (mm) | M6-M36 | M4-M36 | M36 | M36 |

| Spindle servo motor (KW) | 7.5 | 30 | 11 | 22 |

| Torque (N.m) | 292.6 | 400 | 200(when n<250r/min) | 200(when n<250r/min) |

| Distance between spindle nose and working table(mm) | 260-630/460-830 | 350-800 | 280-780 | 280-780 |

| X axis maxi travel(mm) | 1600 | 2000 | 3000 | 3000 |

| X axis move speed(m/min) | 0-8 | 0-8 | 0-8 | 0-8 |

| X axis servo motor power (KW) | 2.4 | 2.4*2(15N.m) | 2*3KW/( 28.4N.m) | 1*2.4KW/( 15N.m) |

| Y axis maxi travel(mm) | 3000 | 3000 | 3000 | 6000 |

| Y axis move speed(m/min) | 0-8 | 0-8 | 0-8 | 0-8 |

| Y axis servo motor power (KW) | 2.4*2 | 2.4*1(15N.m) | 2*2.4KW/(15N.m) | 2*2.4KW/(15N.m) |

| Z axis maxi travel(mm) | 370 | 450 | 500 | 500 |

| Z axis move speed(m/min) | 0-4 | 0-4 | 0-5 | 0-5 |

| L*W*H(mm) | 4700*3000*2300 | 6600*4600*3350 | 6200*5200*3600 | 8200*4800*3000 |

| Gross Weight(KG) | 21000 | 23000 | 26000 | 35 |

Product detail pictures:

Related Product Guide:

Our company since its inception, constantly regards product or service high quality as business life, continually improve creation technology, make improvements to product high-quality and consistently strengthen business total high-quality management, in strict accordance together with the national standard ISO 9001:2000 for Manufacturer for Cnc Drilling Machine - Gantry CNC drilling machine – FOREST, The product will supply to all over the world, such as: Lisbon, Rio de Janeiro, Kyrgyzstan, Our market share of our products has greatly increased yearly. If you are interested in any of our products or would like to discuss a custom order, please feel free to contact us. We are looking forward to forming successful business relationships with new clients around the world in the near future. We are looking forward to your inquiry and order.

The company's products can meet our diverse needs, and the price is cheap, the most important is that the quality is also very nice.