Low MOQ for Edm Cutting Speed - Opposite dual-spindle turning centers( Machining cutting production line) – FOREST

Low MOQ for Edm Cutting Speed - Opposite dual-spindle turning centers( Machining cutting production line) – FOREST Detail:

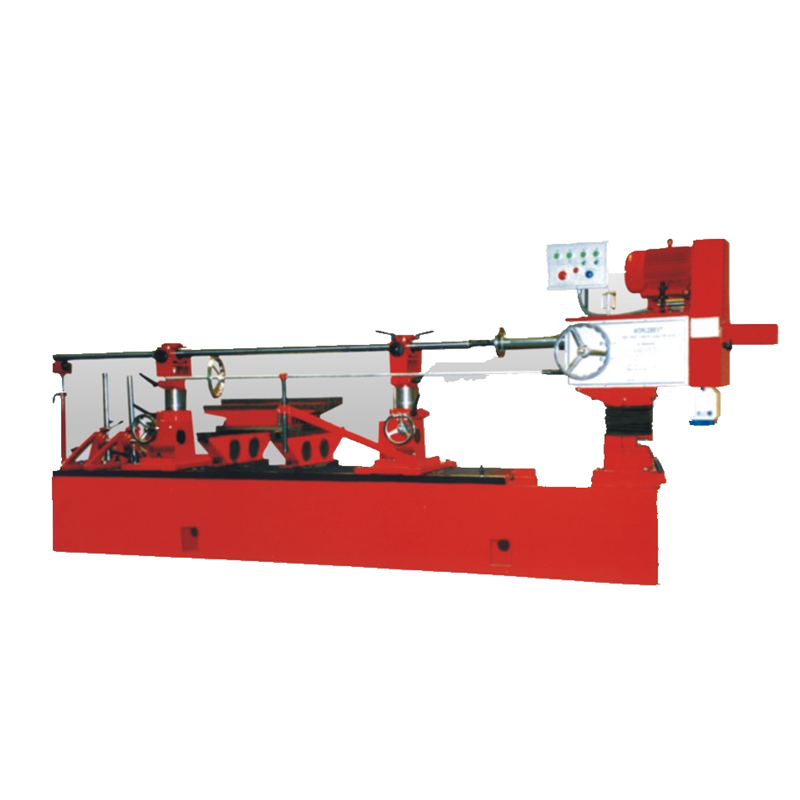

MW series double-spindle double-turret turn-milling compound processing lathe is equipped with a door-type mechanical arm. This product has double-spindle, double-turret, double C-axis, double Y-axis, 8-axis control, 2 sets of 4-axis linkage, closed-loop control, Both turrets are turn-milling compound servo tool holders with drilling and milling tools, and the dual spindles are built-in servo motorized spindles, and the closed-loop control of the high-precision feedback components realizes the high-precision indexing of the two C axes , the resolution of the two spindles is 0.001 degrees, the dual spindles can be continuously indexed and positioned at any index, and can realize flying car feeding and feeding in the process of parts processing, and complete turning and indexing eccentric drilling of complex rotary parts with one feeding Cutting, positioning milling, rotary milling, and all processing procedures of high-speed slotting, to realize the processing of all processes in the sense of complete parts, that is, the workpiece can complete all or most of the processes on one machine tool. It first clamps the workpiece on the first spindle to complete the combined turning and milling processing, and the manipulator automatically transfers the workpiece to the second spindle for the second turning and milling combined processing. One machine tool realizes the processing process of two machine tools, with high processing accuracy and high efficiency. high. The machine tool can be widely used in aerospace, automobile, ship, power generation equipment, engineering equipment, hardware valves, precision molds, military industry and other industries. A high-rigidity and heat-friendly bed structure is specially designed for it, and the shock-absorbing capacity of turning is increased. Both turrets are equipped with 12-station tool holders, which greatly improves the processing efficiency.

Technical Parameters

| NO | Items | Description |

| 1 | Maxi distance of spindle ends | 735mm |

| 2 | Mini distance of spindle ends | 210mm |

| 3 | Maxi diameter of rods materials | Φ52mm |

| 4 | Maxi diameter of plates materials | Φ160mm |

| 5 | X1/ X2 axes stroke | 160/135mm |

| 6 | X1/ X2 axes fast feeding | 24/24m/min |

| 7 | Z1 /Z2 /B strokes | 503/ 503/ 525 mm |

| 8 | Z1 /Z2 fast feeding | 24/24m/min |

| 9 | Spindle Maxi speed | 6000 rpm |

| 10 | Spindle motor power LR | 7.5/7.5 |

| 11 | Spindle hole diameter | Φ56mm |

| 12 | Spindle center height | 1100mm |

| 13 | Spindle nose size | JIS A2-5 |

| 14 | Cutter Model (up and down) | 12 stations Turret |

| 15 | Up turret Y axes stroke | ±135 (customize option) |

| 16 | Outer diameter cutters | 25*25mm |

| 17 | Boring bars | Φ40mm |

| 18 | X/Z axes serve motor power | 1.8 /1.8 KW |

| 19 | X/Z axes serve motor rotation | 3000/3000 rpm |

| 20 | Coolant tank volume | 150 L |

| 21 | Measure (L*W*H) without waste separator | 2100*1550*2440 |

Product detail pictures:

Related Product Guide:

Our company sticks to the principle of Quality is the life of the company, and reputation is the soul of it for Low MOQ for Edm Cutting Speed - Opposite dual-spindle turning centers( Machining cutting production line) – FOREST, The product will supply to all over the world, such as: Stuttgart, Congo, Qatar, Most problems between suppliers and clients are due to poor communication. Culturally, suppliers can be reluctant to question items they do not understand. We break down people barriers to ensure you get what you want to the level you expect, when you want it. Faster delivery time and the product you want is our Criterion .

This is the first business after our company establish, products and services are very satisfying, we have a good start, we hope to cooperate continuous in the future!