CNC pib polishing rau saw hniav ntau lawm

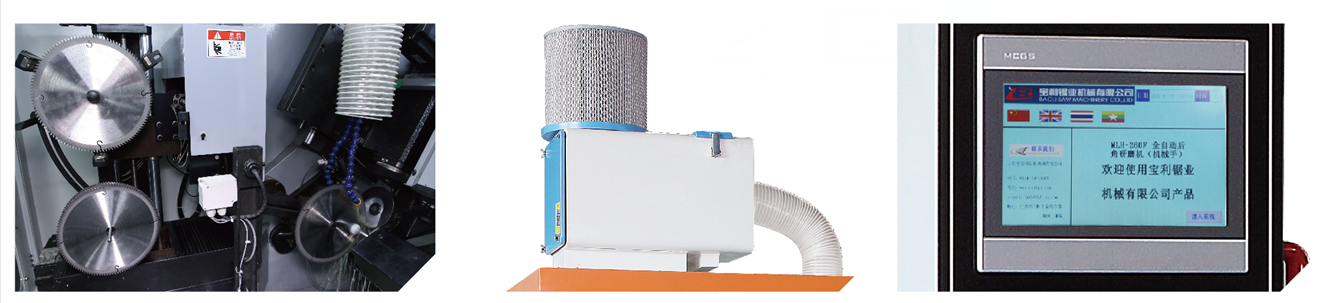

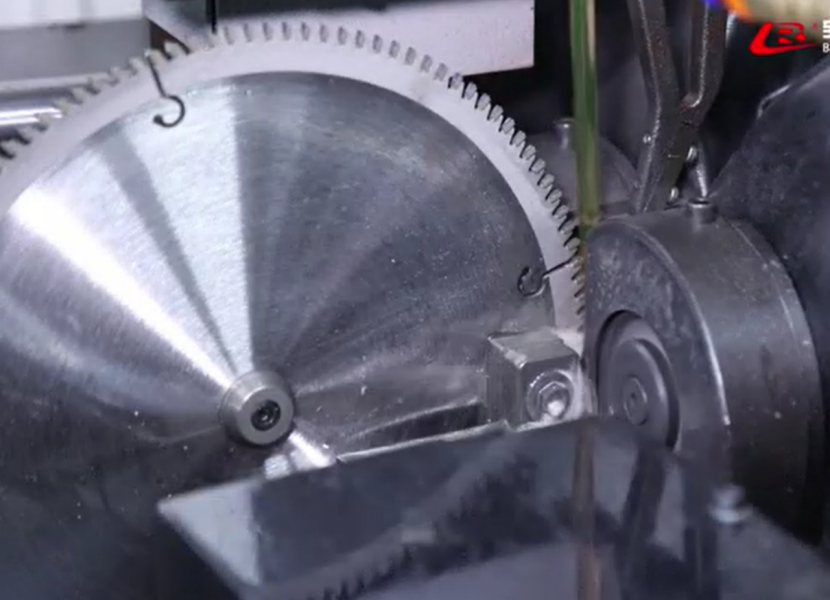

Lub tshuab no yog cov cuab yeej tshwj xeeb rau kev sib tsoo lub kaum sab xis ntawm qib kev tshaj lij carbide ncig pom cov hniav.

Tag nrho nyob rau hauv thiab ib puag ncig tus phooj ywg tsim, tus manipulator cia li clamps sawb, thiab ib tug neeg muaj peev xwm ua hauj lwm 10-15 daim ntawm cov khoom.

Omron PLC thiab Mitsubishi servo motors yog siv los siv micro-feeding, tus nqi pub mis tuaj yeem teeb tsa, thiab cov khoom siv tau zoo rigidity.Silver hom pob screws thiab precision-qib linear slides yog siv.Vertical sib tsoo precision yog siab thiab kev sib tsoo log poob qis.

Qhov kev teeb tsa yog hloov tau thiab muaj ntau haiv neeg, thiab txoj haujlwm pub thiab txoj haujlwm tshem tawm tuaj yeem raug xaiv arbitrarily kom paub ntau yam kev sib tsoo.

| NO | Cov khoom | Parameter |

| 1 | Hniav | Φ100-Φ315mm (Φ76-Φ269mm lwm tus qauv) |

| 2 | Arbor Loj | Φ12-Φ50mm (kev cai txiav txim muaj) |

| 3 | Hniav Pitch | 5-65 hli |

| 4 | Pem hauv ntej lub kaum sab xis | -5 ° - +30 ° |

| 5 | Radial Angle | -5° — 5° |

| 6 | Perigon Angle | 0 - 5 ° |

| 7 | Sib tsoo ntug dav | 1.5-13 hli |

| 8 | Sib tsoo ntug thickness | 1.5-4 hli |

| 9 | Sib tsoo ntug ntev | 3-12 hli |

| 10 | Sib tsoo precision | ≤ 0.02 hli |

| 11 | Sib tsoo ceev | 20 PCS hniav / min |

| 12 | Pob zeb diamond log | Φ100xΦ20x4mm |

| 13 | Pob zeb diamond log grit | 220 # 280 # lossis lwm yam |

| 14 | Ua haujlwm cua siab | ≥0.5Mpa |

| 15 | Tag nrho lub zog | 3.5 KW TSI |

| 16 | Qhov hnyav | 1796 KWG |

| 17 | Qhov ntev | 1805x1400x2603 mm |