Factory making Engine Repairing Cylinder Honing - High quality diamond grinding wheels – FOREST

Factory making Engine Repairing Cylinder Honing - High quality diamond grinding wheels – FOREST Detail:

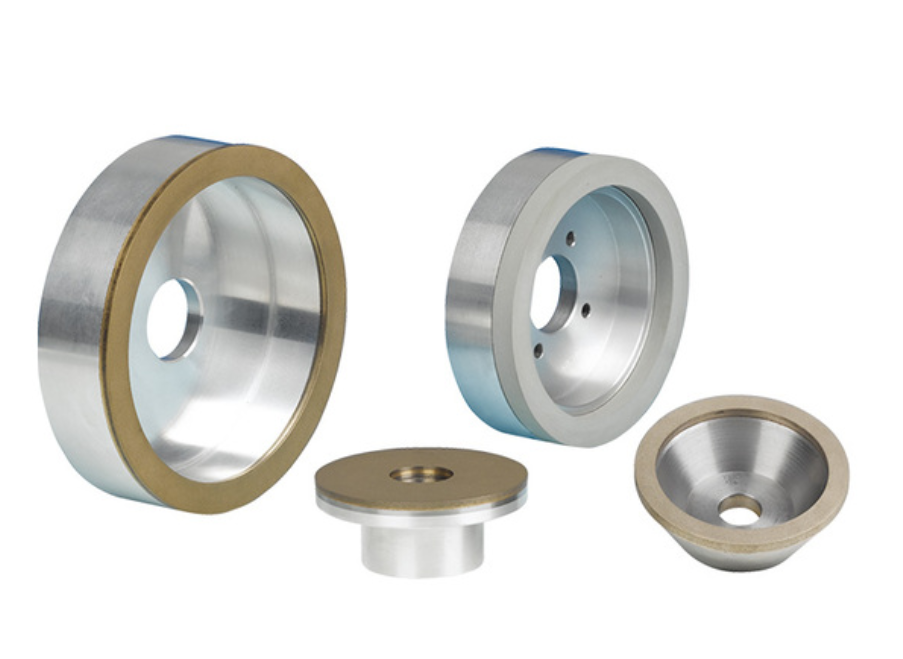

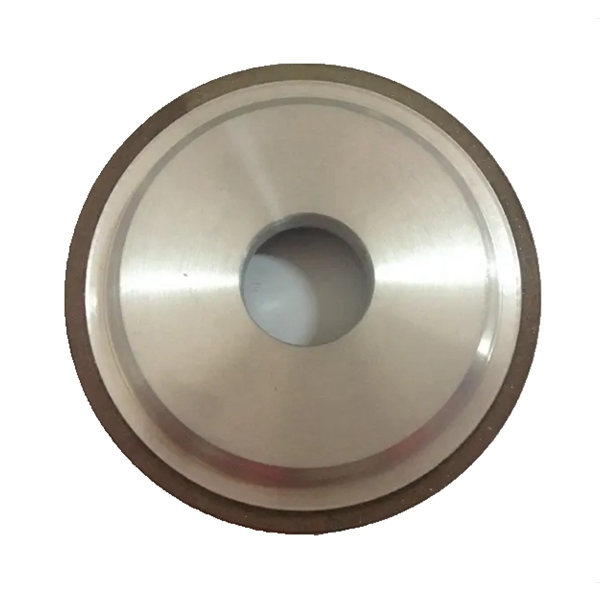

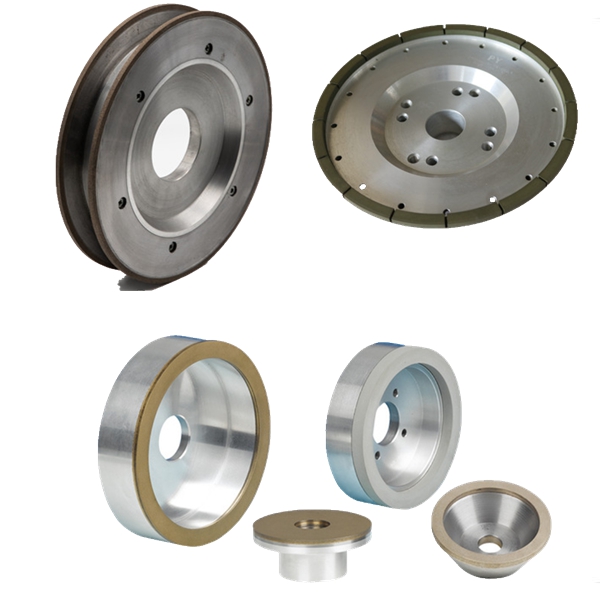

The structure of diamond grinding wheel is different from that of ordinary abrasive grinding wheel. Generally, it is composed of diamond abrasive layer, transition layer and matrix. Diamond grinding wheel is a super-hard abrasive grinding wheel, which has very obvious characteristics and advantages compared with ordinary abrasive grinding wheels. Diamond grinding wheel can be divided into: resin bond diamond grinding wheel; ceramic bond diamond grinding wheel; electroplating bond diamond grinding wheel; metal bond diamond grinding wheel (bronze bond diamond grinding wheel). Due to the characteristics and advantages of diamond abrasives, diamond grinding wheels are ideal tools for grinding hard and brittle materials such as glass, ceramics, gemstones, stone, and cemented carbide.

1. Classification by binder: diamond grinding wheels include metal diamond grinding wheels, resin diamond grinding wheels, ceramic diamond grinding wheels, and electroplating diamond grinding wheels.

2. Classification by shape: According to different shapes, diamond grinding wheels can be divided into diamond grinding wheels, diamond grinding heads, diamond oil stones and diamond tools.

(1) Diamond grinding wheels include general grinding wheels, such as flat grinding wheels, cup grinding wheels, dish grinding wheels, cylindrical grinding wheels, etc.; special grinding wheels, such as fine grinding discs, electrolytic grinding grinding wheels, nesting knives, grinding discs, etc.

(2) The diamond grinding head includes cylindrical grinding head and special-shaped grinding head.

(3) Diamond tools include machine tools, such as reamers, rollers, dressing blocks, etc.; hand tools such as assorted files, plate files, etc.

3. Classification by grinding method: According to different grinding methods, diamond grinding wheels can be divided into: diamond plane grinding wheel, diamond internal grinding wheel, diamond external grinding wheel, diamond tool grinding wheel, diamond cutting tool grinding wheel, diamond cutting wheel Grinding wheel, diamond special grinding wheel.

Classification method of CBN grinding wheels: classification by shape, classification by binder, classification by grinding method.

1. Classification by binder: CBN grinding wheels include metal CBN grinding wheels, resin CBN grinding wheels, ceramic CBN grinding wheels, and electroplating CBN grinding wheels.

2. Classification by shape: According to different shapes, CBN grinding wheels can be divided into CBN grinding wheels, CBN grinding heads, CBN tools and CBN grinding stones.

(1) CBN grinding head includes cylindrical grinding head and special-shaped grinding head.

(2) CBN grinding wheels include general grinding wheels, such as flat grinding wheels, cup grinding wheels, dish grinding wheels, cylindrical grinding wheels, etc.; special grinding wheels, such as fine grinding discs, electrolytic grinding grinding wheels, nesting knives, grinding discs, etc.

(3) CBN tools include machine tools, such as reamers, rollers, dressing blocks, etc.; hand tools such as assorted files, plate files, etc.

3. Classification by grinding method: According to different grinding methods, CBN grinding wheels can be divided into: CBN tool grinding wheel, CBN cutting tool grinding wheel, CBN plane grinding wheel, CBN internal grinding wheel, CBN external grinding wheel

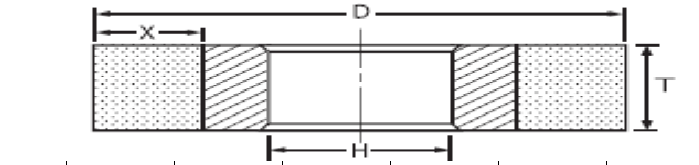

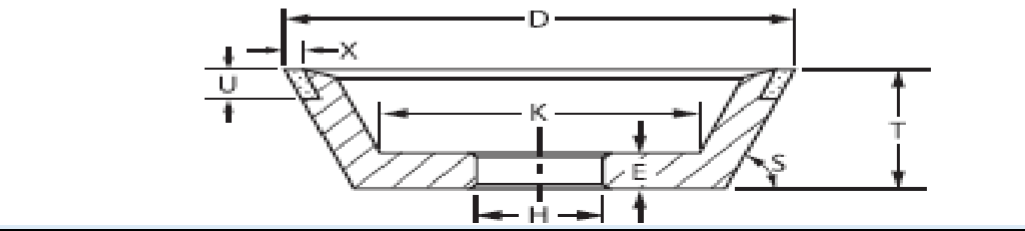

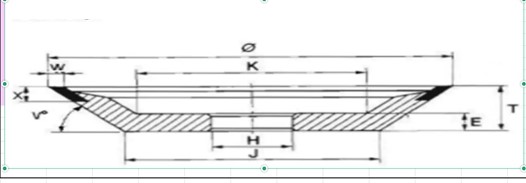

Custom drawings samples

Product detail pictures:

Related Product Guide:

Quality initial, Honesty as base, Sincere support and mutual profit is our idea, so as to build repeatedly and pursue the excellence for Factory making Engine Repairing Cylinder Honing - High quality diamond grinding wheels – FOREST, The product will supply to all over the world, such as: America, Orlando, Rio de Janeiro, We have a dedicated and aggressive sales team, and many branches, catering to our customers. We are looking for long-term business partnerships, and ensure our suppliers that they will definitely benefit in both short and long run.

The company comply with the contract strict, a very reputable manufacturers, worthy a long-term cooperation.