Factory making Engine Repairing Cylinder Honing - High precision CNC Profile grinder machine – FOREST

Factory making Engine Repairing Cylinder Honing - High precision CNC Profile grinder machine – FOREST Detail:

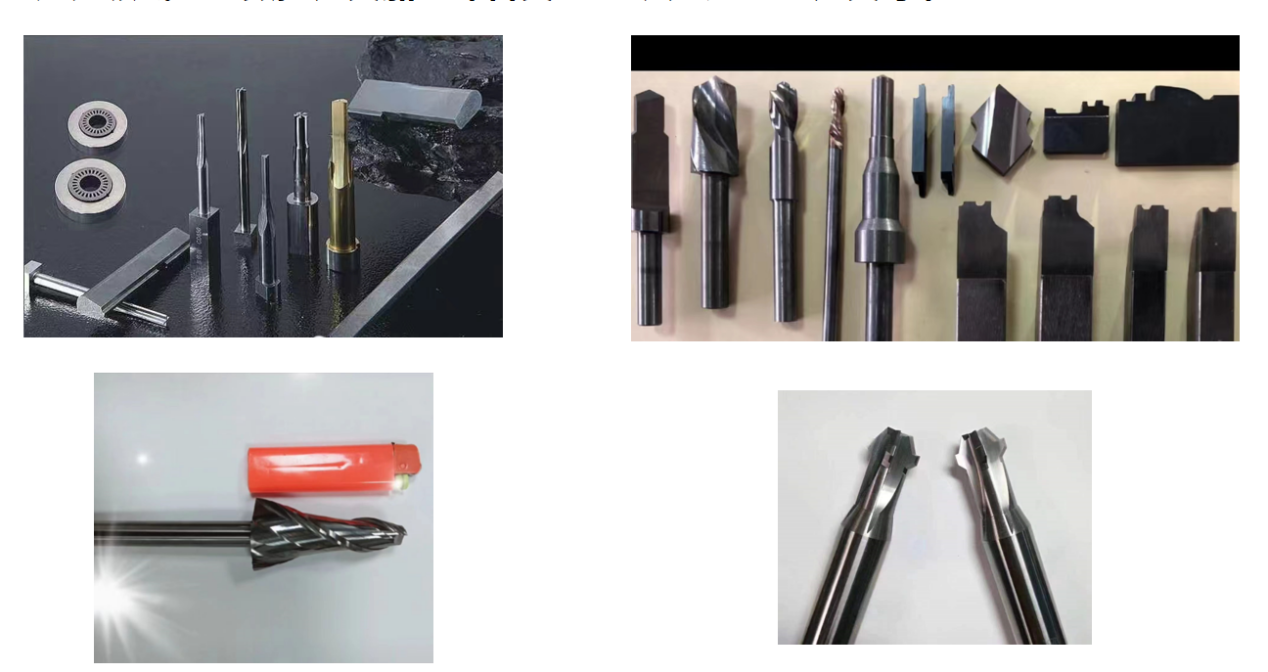

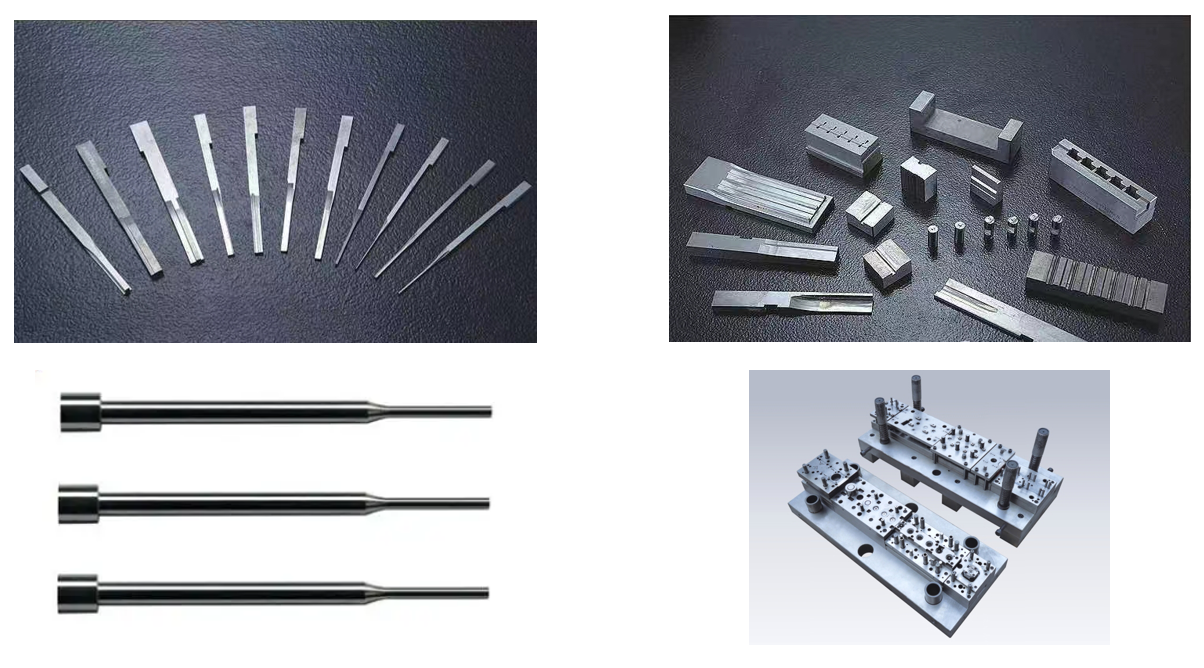

We are the manufacturer of this type grinder in China. In 2011 our team make this machine successful and widely used in China market. After more than ten years of development, the technology has been very mature, and has been far ahead in the field of domestic optical curve grinders, involving metal stamping, roll extrusion molding, CNC tools Processing and other industries.

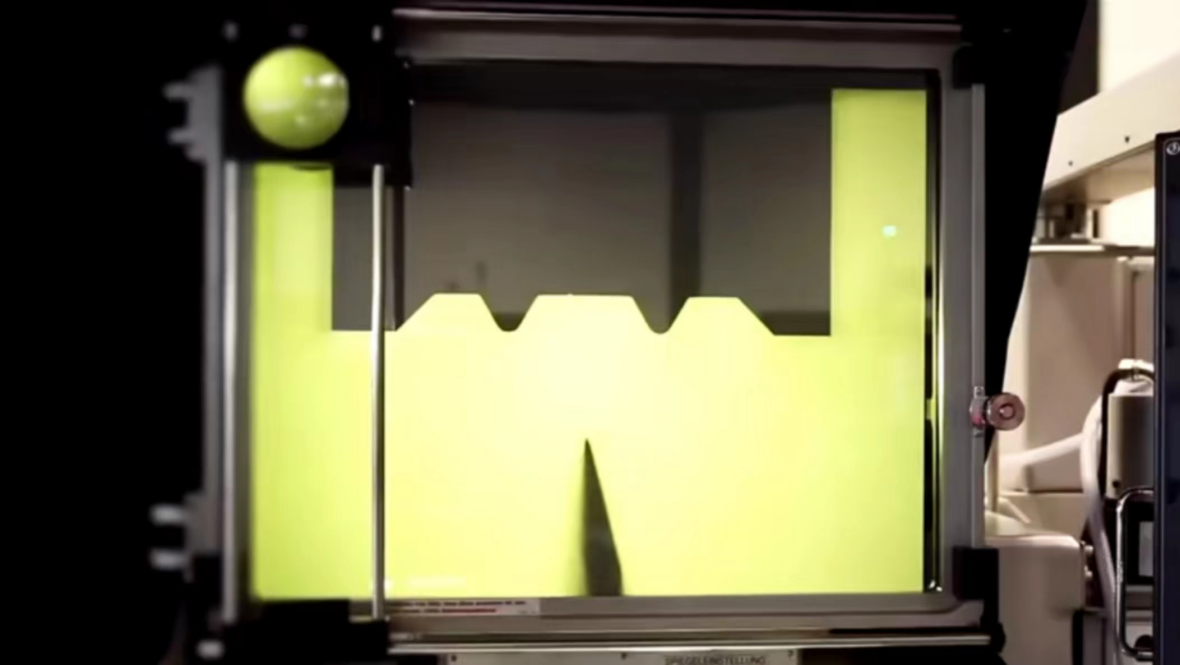

High-definition projection: magnify the workpiece to 20 or 50 times for grinding, the minimum thickness of the grinding wheel is 0.05mm, the minimum cutting amount can reach 0.1 micron, and the error is ±1 micron, which can realize 2D complex contour processing with or without penetration

Features

Imported CNC system, servo drive, higher precision and more stable Machinable special-shaped surface groove High wear resistance, high rigidity, high stability Processing accuracy can reach 0.001mm The Ra value of the processed surface can reach 0.1μm The minimum processing R angle is R0.03mm, and the minimum cleaning angle is R0.02mm XYUV four-axis linkage, multi-stage processing, greatly improving work efficiency The four-axis movement is silent, the machine tool runs without vibration, and the operation is more comfortable It can grind various materials including super cemented carbide, tungsten steel, white steel, ceramics, plastics, etc. LED lighting, reduce lamp consumption

Technical Parameters

1. Projection magnification within 0.002mm, with back projection

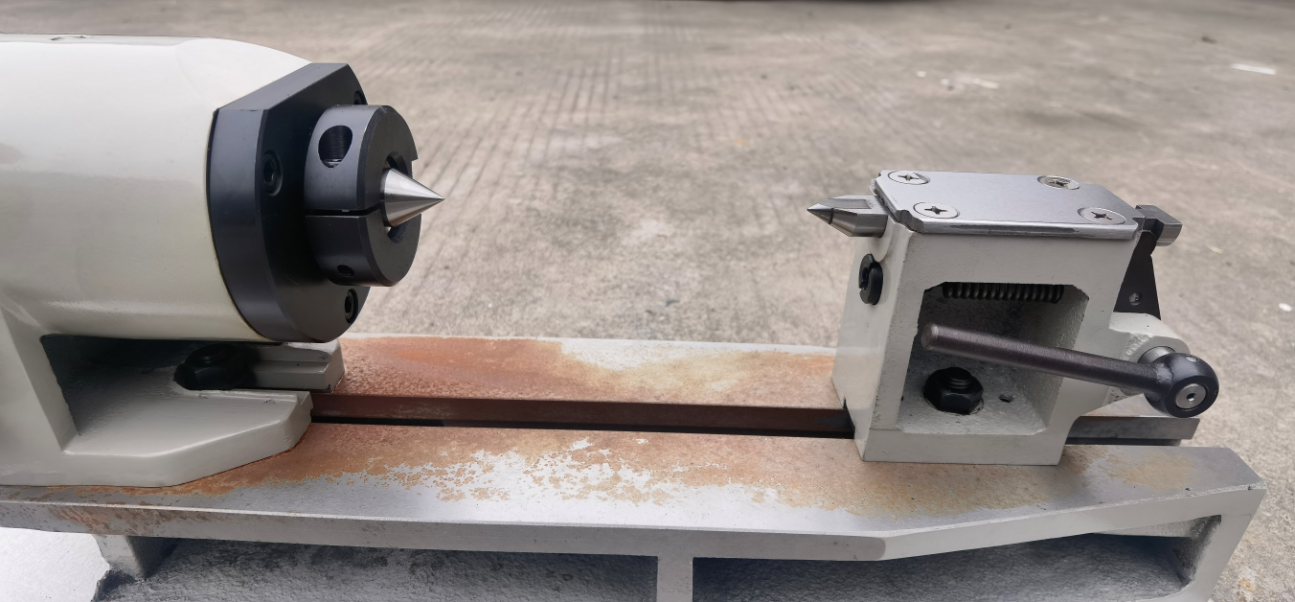

2. The moving stroke of the worktable is 200mm, and the pulling number is 0.001mm

3. The stroke of the grinding wheel lifting shaft is 160mm

4. The drop angle of the nose is 10°

5. Left and right swing angle 20°

6. Projection height 200mm 9. Spindle speed 30,000, 10,000 rpm silent 10. Workbench lifting stroke 200mm

7. One cooling cycle machine, one dust-free vacuum cleaner, one transformer.

Applications :

Product detail pictures:

Related Product Guide:

Our solutions are widely recognized and trusted by consumers and will meet up with constantly developing financial and social requires for Factory making Engine Repairing Cylinder Honing - High precision CNC Profile grinder machine – FOREST, The product will supply to all over the world, such as: Venezuela, Greenland, Ecuador, Meanwhile, we're building up and consummating triangle market & strategic cooperation in order to achieve a multi-win trade supply chain to expand our market vertically and horizontally for a brighter prospects. development. Our philosophy is to create cost-effective products, promote perfect services, cooperate for long-term and mutual benefits, firm a comprehensive mode of excellent suppliers system and marketing agents, brand strategic cooperation sales system.

This is a honest and trustworthy company, technology and equipment are very advanced and the prodduct is very adequate, there is no worry in the suppliment.