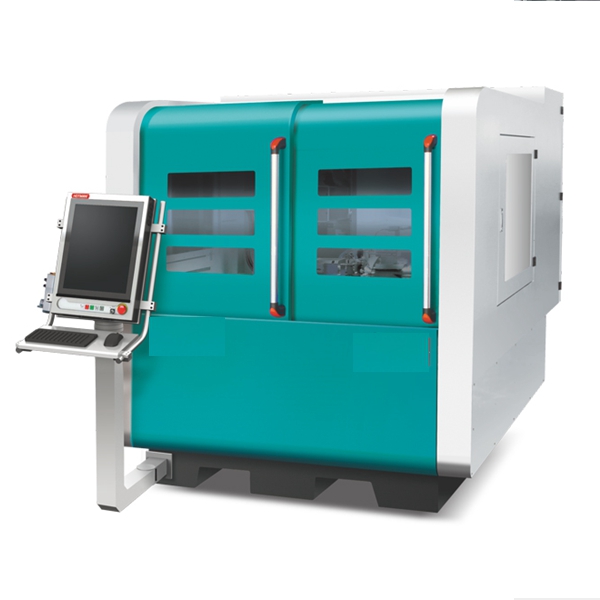

Factory made hot-sale Honing Process - High Precision CNC Swiss CNC Grinding Machine for Grinding Carbide Rods – FOREST

Factory made hot-sale Honing Process - High Precision CNC Swiss CNC Grinding Machine for Grinding Carbide Rods – FOREST Detail:

This Swiss CNC grinding machine is designed as professional manufacturer who is top manufacturer of this swiss griinding machine in China. This Swiss grinding machines are sold to many enterprise. The Swiss grinding machine is designed for the processing of precision machine tools, to achieve very precision accuracy rods. Also this grinding machine can get many different shapes rods .

The control system is smart to process, and have a online tracking in touch screen. The machine keep high precision to micrometer.

1. Available material: hard raw material, like high-speed steel, carbide rod….

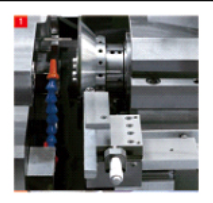

2. Workpiece grinding method: Swiss type grinding, the angle of the rough grinding wheel is 11°, the fine grinding wheel is 90°.

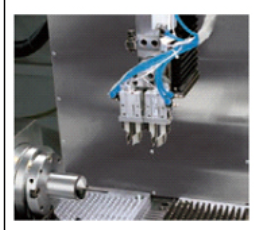

3. Processing : The robot arm automatically feeds and receives the material, and the feed is completed at one time.

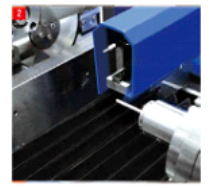

4. Grinding time: for Φ4 raw material to finished forming, the grinding time is about 65 seconds per piece, and the speed ,and the speed can be adjusted according to the actual situation.

5. The available grinding diameters : 0.05 – 20.0mm.

6. Length of grinding workpiece: up to 200mm.

7. Rotation way of working head spindle: fixed

8. Working head spindle speed: 0 — 2000rpm

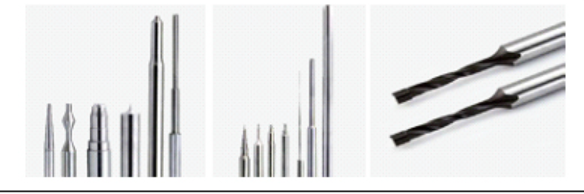

Finished goods as following

| NO | Items | Des | |

| H3 grinding machine | |||

| 1 | Clamping workpiece dia range | 0.5-20mm | |

| 2 | Cutting workpiece dia range | 0.05-20mm | |

| 3 | Clamping/Cutting workpiece length | 300/200mm | |

| 4 | Control system | ANCA—X/Y/Z/Z’ | |

| 5 | Workpiece feeder system(CNC-3 axis) | ANCA—U/V/W | |

| 6 | Rough

grinding |

Grinding wheel size(OD *W * ID) | 250×20×31.75 |

| 7 | Grinding wheel speed (electric spindle) | 0~9000 rpm | |

| 8 | Grinding wheel line speed | 90 m/s | |

| 9 | Grinding wheel spindle motor | 20 KW | |

| 10 | Fine grinding | Grinding wheel size(OD *W * ID) | 150×20×31.75 |

| 11 | Grinding wheel speed (electric spindle) | 0~12000 rpm | |

| 12 | Grinding wheel line speed | 90 m/s | |

| 13 | Grinding wheel spindle motor | 5 KW | |

| 14 | X/Y/Z/Z’ axis feeding unit | 0.001mm | |

| 15 | X axis moving length (rough grinding wheel axis) | 73mm | |

| 16 | Y axis moving length (fine grinding wheel axis) | 40mm | |

| 17 | Z axis moving ( working head) | 374mm | |

| 18 | Z’ axis moving ( the guide of Z axis ) | 52mm | |

| 19 | X/Y/Z/Z’ axis servo motors | 2.0 KW | |

| 20 | Working head table motor | 1.0 KW | |

| 21 | Working head spindle speed | 0-3000 rpm | |

| 22 | High pressure oil pump | 0.25 KW | |

| 23 | Working head spindle rotate way | fixed | |

| 24 | Length position way | Front positioning | |

| 25 | Robot arm U/V/W axis servo motor | 1.0KW | |

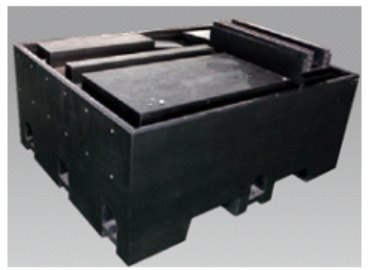

| 26 | Cutting liquid tank | 300*300*1000mm | |

| 27 | Gross weight | 5000 KG | |

| 28 | Dimension | 2390*2752*2050mm | |

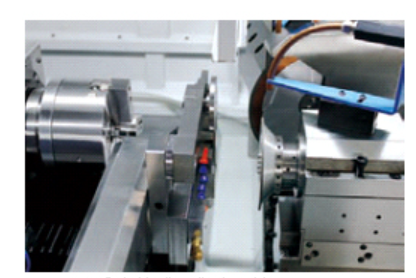

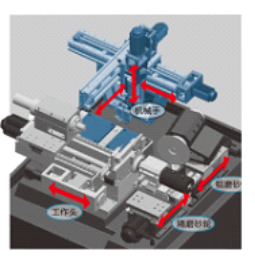

Main Structures of Swiss Grinding Machine

Centerless Grinding Machine make high precision carbide rods

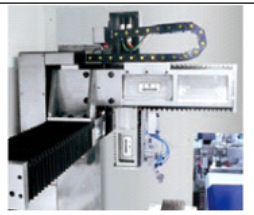

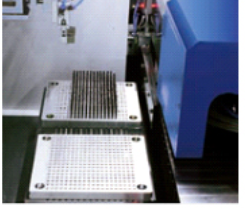

Product detail pictures:

Related Product Guide:

We take customer-friendly, quality-oriented, integrative, innovative as objectives. Truth and honesty is our management ideal for Factory made hot-sale Honing Process - High Precision CNC Swiss CNC Grinding Machine for Grinding Carbide Rods – FOREST, The product will supply to all over the world, such as: Surabaya, Sheffield, Paraguay, The best and original quality for spare parts is a most important factor for transportation. We may stick on supplying original and good quality parts even a little profit earned. God will bless us to do kindness business forever.

We feel easy to cooperate with this company, the supplier is very responsible, thanks.There will be more in-depth cooperation.