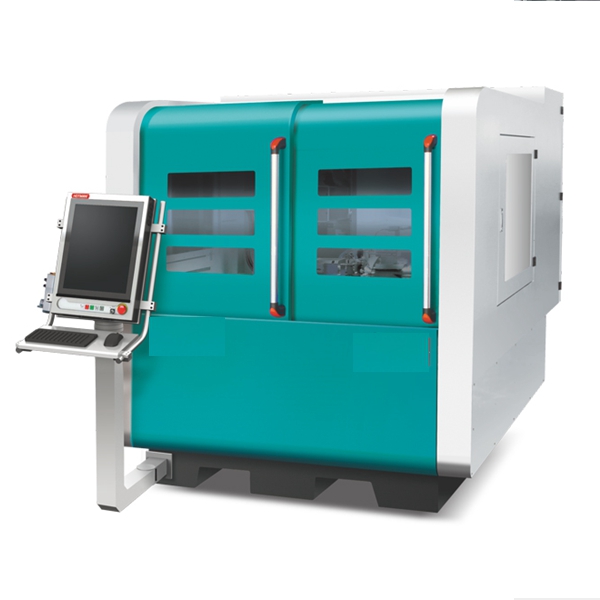

factory customized Cnc Deep Honing Machine - Manual & auto surface grinding machine – FOREST

factory customized Cnc Deep Honing Machine - Manual & auto surface grinding machine – FOREST Detail:

Product Description

The spindle of M250 manual surface grinding machine adopts P4 grade precision bearing, which has high reliability and convenient maintenance.

The machine tool adopts double V sticking plastic horizontally , one V and one flat longitudinal track , and ball steel track (adopt overall quenching ),which has high stability and accuracy, and easy and flexible operation . The movable parts are lubricated by hand-pulled oil lumps and equipped with various special accessories to meet the requirements of arc grinding and other complex forming.

M-250YHAS hydraulic automatic display surface grinding machine, the workbench for manual movement around hydraulic automatic system system before and after the main mechanical valve for grinding machine is special valve, divided into two parts , mechanical commutation control, throttle speed regulation control throttle control part and unloading function, which can realize the workbench of the rev. Stop this valve has buffer adjustment function of the machine tool is convent and flexible and reliable operation without vibration precision stability of thermal stability of low noise and easy maintenance.

| Models | M250 | M250AH | M250YH | M250YHAS | ||

| Working table(mm) | 500*250 | 500*250 | 500*230 | 500*250 | ||

| Max table travel(mm) | 550 | 550 | 550 | 550 | ||

| Max cross travel(mm) | 280 | 280 | 250 | 280 | ||

| Distance between table and Spindle center | 470 | 470 | 470 | 470 | ||

| Max table load(kg) | 100 | 100 | 300 | 300 | ||

| Tee slot(nos*width) | 14×1 | 14×1 | 14×1 | 14×1 | ||

| Table speed(m/min) | Manual | 0-25 | 5-25 | 5-25 | ||

| Crossfeed handwheel | 1 grade | 0.02 | 0.02 | 0.02 | 0.02 | |

| 1 rev | 2.5 | 2.5 | 2.5 | 2.5 | ||

| Auto crossfeet of saddle(mm) | — | 0.5-12 | 0.5-12 | 0.5-12 | ||

| Power cross feed | 50HZ | — | 750 | 750 | 750 | |

| 60HZ | — | 950 | 950 | 950 | ||

| Grinding wheel | 200*17*31.75/32 | 200*17*31.75/32 | 180*13*31.75/32 | 200*17*31.75/32 | ||

| Spindle speed | 50HZ | 2850 | 2850 | 2850 | 2850 | |

| 60HZ | 3420 | 3420 | 3420 | 3420 | ||

| Vertical handwheel | 1 grade | 0.01 | 0.01 | 0.01 | 0.01 | |

| 1 rev | 1.25 | 1.25 | 1.25 | 1.25 | ||

| Spindle Motor(kw) | 1.5 | 1.5 | 1.5 | 1.5 | ||

| Hydraulic motor(kw) | 0.75 | — | 0.75 | 0.75 | ||

| Dust collector motor(kw) | — | – | – | – | ||

| Coolant motor(w) | 40 | 40 | 40 | 40 | ||

| Crossfeed motor(w) | 60 | 60 | 60 | 60 | ||

| Floor Space(mm) | 2500*1500*1800 | 2500*1500*1800 | 2500*1500*1800 | 2500*1500*1800 | ||

| Net weight(KG) | 1000 | 1000 | 1000 | 1000 | ||

| Gross weight (KG) | 1100 | 1100 | 1100 | 1100 | ||

| Power supply | 380V, 3 phase, 50HZ/60HZ, customized | |||||

Product detail pictures:

Related Product Guide:

We've been committed to offering easy,time-saving and money-saving one-stop purchasing support of consumer for factory customized Cnc Deep Honing Machine - Manual & auto surface grinding machine – FOREST, The product will supply to all over the world, such as: Hyderabad, Iraq, Slovenia, So that you can utilize the resource from the expanding info in international trade, we welcome shoppers from everywhere on-line and offline. In spite of the good quality solutions we provide, effective and satisfying consultation service is supplied by our professional after-sale service team. Product lists and detailed parameters and any other info weil be sent to you timely for your inquiries. So you should make contact with us by sending us emails or call us if you have any questions about our corporation. ou may also get our address info from our web page and come to our company to get a field survey of our merchandise. We've been confident that we have been going to share mutual achievement and create strong co-operation relations with our companions in this marketplace. We're searching forward for your inquiries.

It can be said that this is a best producer we encountered in China in this industry, we feel lucky to work with so excellent manufacturer.