Big discounting Engine Honing Machine - Good Prices Simple Vertical Honing Machines – FOREST

Big discounting Engine Honing Machine - Good Prices Simple Vertical Honing Machines – FOREST Detail:

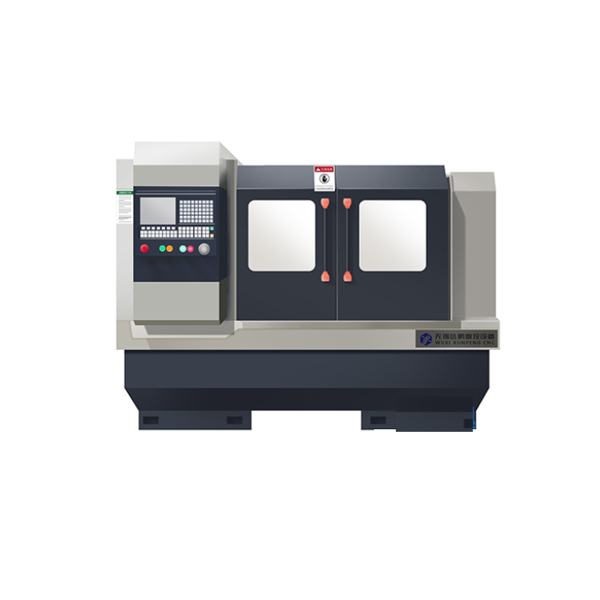

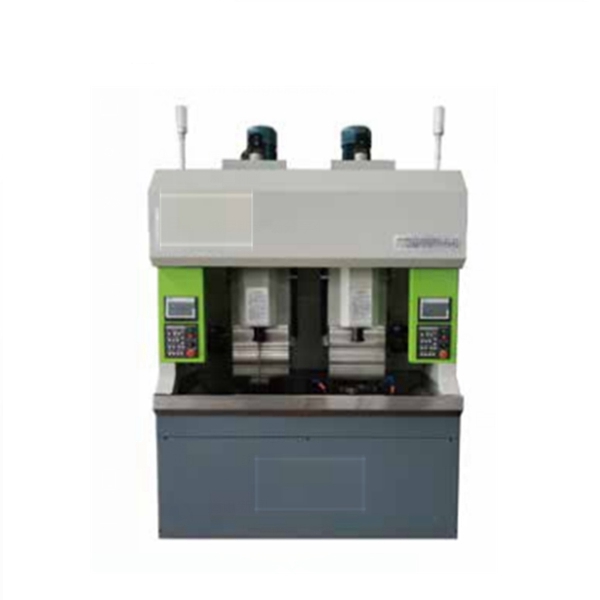

This machine tool is suitable for processing various engine cylinder holes, cylinder casing holes, hydraulic valve body holes, piston ring holes and other precise through holes and non-through holes. The parts processed by this machine tool can be either cast iron or steel, including heat treatment machine parts. The workbench is controlled by the motor to move left and right. The workbench has high positioning accuracy and can be positioned at any point within the travel range. Equipped with a two-stage filter constant temperature cooling system for magnetic roll paper tape. With automatic online measurement function It has the function of double feed, that is, it can realize the honing of platform texture or the rough honing and fine honing of work on one grinding head, which improves the honing effect

Technical Parameters

| NO | Items | Description | ||

| 1 | Model | LHCA 10×32 | LHSCA 18×50-Y | LHCC 20×40 |

| 2 | Maxi diameter | Φ100mm | Φ180mm | Φ200mm |

| 3 | Mini diameter | Φ10mm | Φ12mm | Φ50mm |

| 4 | Maxi stroke length | 320mm | 650mm | 550mm |

| 5 | Distance between spindle end to worktable | 880mm | 1700mm | 1520mm |

| 6 | Spindle center to column | 200mm | 350mm | 350mm |

| 7 | Stroke speed | 3-18 m/min | 3-28 m/min | 3-28 m/min |

| 8 | Spindle rotation speed | stepless adjustment | 50-300rpm stepless adjustment | 60-400rpm stepless adjustment |

| 9 | Worktable stroke | / | 750mm | Maxi to 800mm |

| 10 | Worktable size | 600*600mm | 1250*500mm | 1250*500mm |

| 11 | Worktable height | 600mm | 600mm | 600mm |

| 12 | Spindle motor | 3 KW | 7.5 KW | 7.5 KW |

| 13 | Hydraulic motor power | 4 KW | 7.5 KW | 7.5 KW |

| 14 | Measure | 1600*2370*3000mm | 1460*1390*4133mm | 1390*1400*3300 |

| 15 | Notes | Worktable could be movable or fixed | ||

| 16 | Power supply | 380V, 50HZ, 3phase | 380V, 50HZ, 3phase |

| NO | Items | Description | ||

| 1 | Model | LHCD 40×120 | LHCB 20×100 | LHCD 90×120 |

| 2 | Maxi diameter | Φ400mm | Φ200mm | Φ900mm |

| 3 | Mini diameter | Φ80mm | Φ40mm | Φ80mm |

| 4 | Maxi stroke length | 1200mm | 1150mm | 1500mm |

| 5 | Distance between spindle end to worktable | 3480mm | 2603mm | 3480mm |

| 6 | Spindle center to column | 450mm | 370mm | 800mm |

| 7 | Stroke speed | 5-18 m/min | 3-30 m/min | 5-18 m/min |

| 8 | Spindle rotation speed | 30-150 rpm | 50-80 rpm | 30-150rpm |

| 9 | Worktable stroke | Maxi to 800mm | 500mm | Maxi to 1000mm |

| 10 | Worktable size | 1600*700mm | 500*1250mm | 3500*1400mm |

| 11 | Worktable height | 600mm | 450mm | 600mm |

| 12 | Spindle motor | 15 KW | 7.5 KW | 22 KW |

| 13 | Hydraulic motor power | 11 KW | 7.5 KW | 11 KW |

| 14 | Measure | 2000*1980*5400mm | 1520*1950*4830mm | 3400*2800*5400 |

| 15 | Notes | Worktable could be movable or fixed | ||

| 16 | Power supply | 380V, 50HZ, 3phase | 380V, 50HZ, 3phase | 380V, 50HZ, 3phase |

More machine to contact with us.

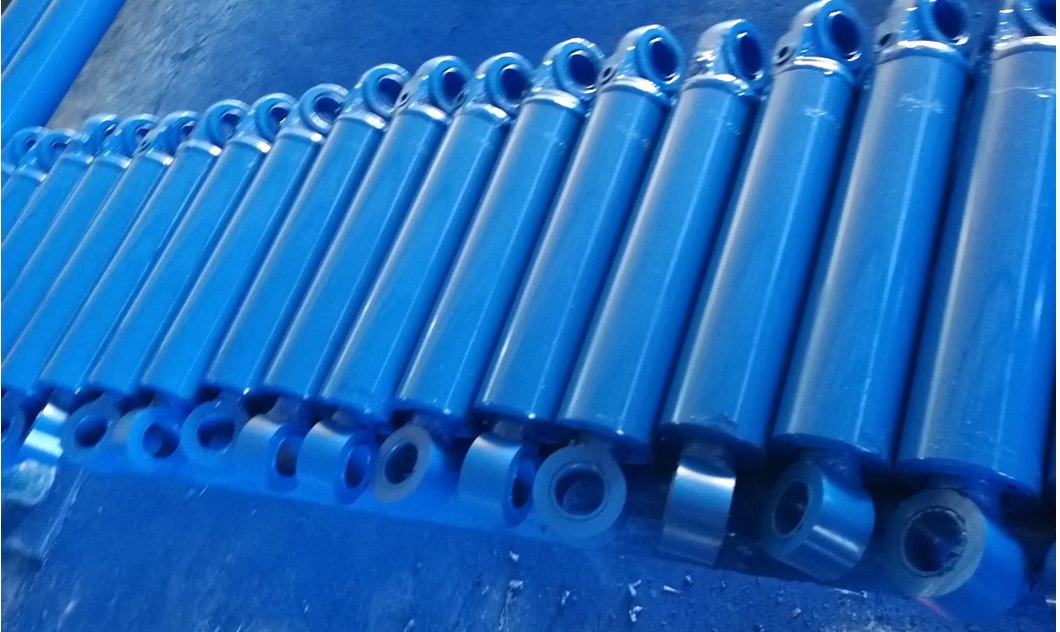

Product detail pictures:

Related Product Guide:

Persisting in High quality, Prompt Delivery, Aggressive Price, we have established long-term cooperation with clientele from both equally overseas and domestically and get new and old clients' higher comments for Big discounting Engine Honing Machine - Good Prices Simple Vertical Honing Machines – FOREST, The product will supply to all over the world, such as: Moldova, Netherlands, Cambodia, The company attaches great importance to product quality and service quality, based on the business philosophy good with people, genuine to whole world, your satisfaction is our pursuit. we design products, According to customer's sample and requirements, to meet the needs of the market and offer different customers with personalized service. Our company warmly welcomes friends at home and abroad to visit, to discuss cooperation and seek common development!

The factory technical staff not only have high level of technology, their English level is also very good, this is a great help to technology communication.