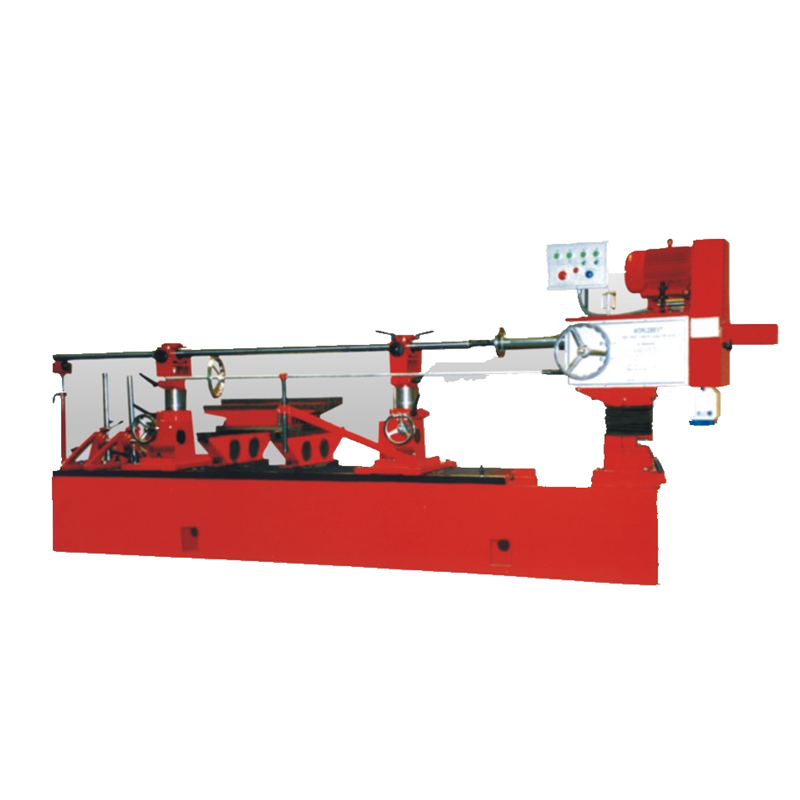

Best quality Hole Drill Machine - Tower CNC complete processing equipment – FOREST

Best quality Hole Drill Machine - Tower CNC complete processing equipment – FOREST Detail:

Product Description

The CNC angle steel drilling production line is a kind of iron tower processing equipment used for the production of angle steel towers in the power transmission and transformation and communication industries. It can also be used for steel stamping, drilling and cutting of angle steel components in the construction industry, railway and bridge engineering. It is also called a CNC angle steel joint production line because it can jointly complete the functions of stamping, drilling and cutting. In the iron tower processing equipment, there are two main processing methods used in the hole making process, one is punching, the other is drilling, which is different from the CNC angle steel punching production line, which is usually also called CNC angle steel drilling production line.

Machine features

1. The CNC angle steel drilling production line has independent hydraulic power mechanism and electrical CNC system, and adopts centralized control. At the same time, in order to facilitate the adjustment of the host’s mold and other parts, it also has partial decentralized control actions.

2. The main machine of the CNC angle steel drilling production line adopts a steel plate combination mechanism. Small size, light weight and good rigidity. The hydraulic system controls the movement of each part through the reversal of the solenoid valve, with a simple structure and convenient use.

3. The angle steel production line is equipped with two drilling units, and the drilling unit on each side is equipped with three sets of drilling dies.

4. The marking unit is equipped with four groups of replaceable word boxes, and four kinds of workpieces can be processed at one time.

5. There are three CNC servo axes, which respectively complete the adjustment of the hole distance of the angle steel and the quasi-distance of the two sides, and the automatic positioning accuracy is high.

6. The use of world-famous brands for hydraulic components, pneumatic components and electrical components ensures the long-term and reliable operation of the system.

7. The numerical control angle steel drilling production line has high positioning accuracy in the hole distance direction. The feeding part is equipped with a special measuring encoder, which is used to feedback the actual position of the feeding trolley and compensate and correct the position error in real time, forming a closed-loop control system.

Parameter

| Model | JX2532 |

| Available angle steel range (mm) | 140x140x10~250x250x35 |

| Max available drilling diameter (mm) | Φ30×35(Q235/Q345/Q420, GB standard) |

| Print pressure(KN) | 1000/1250 |

| Max angle steel length(m) | 14 |

| Accurate distance range(mm) | 50-220 |

| Drill per side (nos) | 3 |

| Nos of Print font groups | 4 |

| Print font size | 14x10x19 |

| CNC spindles number | 3 |

| Feeding speed of angle steel (m/min) | 60 |

| Drilling spindle rotation(r/min) | 180-560 |

| Power supply | 380V, 50HZ, 3 Phase, or customized |

| Measure (LxWxH)(m) | 29×8.9×2.5 |

| Weight(KG) | 17000 |

1. The numerical control system used in the angle steel drilling production line not only realizes numerical control in the longitudinal direction of the angle steel to ensure the spacing of the holes, but also adopts numerical control on the two wings of the angle steel, thus realizing the multi-pitch drilling of the two wings of the angle steel.

2. The standard configuration of this CNC angle steel drilling production line does not include a shearing unit, but a double-edged shearing unit can be purchased separately.

3. The self-developed computer control software has complete functions and is convenient for programming, management and fault diagnosis.

4. Realize the drilling of multiple varieties and multiple apertures. It can meet the processing requirements of angle steel with wing width less than 250mm required by various types of iron towers. Compared with traditional angle steel processing technology, the use of CNC iron tower processing equipment can greatly reduce the labor intensity of workers, shorten auxiliary working hours, and improve overall work efficiency And machining accuracy.

5. Control the soft armor to monitor the operation of the machine at any time. When a fault occurs, the screen will display the detailed cause and treatment method of the fault, which makes the fault diagnosis and equipment maintenance more convenient and quick, and greatly saves the maintenance downtime.

6. Realize the networking requirements of production equipment and ERP, improve the operating efficiency of the equipment, strengthen the management and control capabilities of the equipment, and can increase or decrease different functions according to the current management requirements of the user’s factory.

Product detail pictures:

Related Product Guide:

The pretty loaded projects management experiences and one to a person support model make the high importance of business enterprise communication and our easy understanding of your expectations for Best quality Hole Drill Machine - Tower CNC complete processing equipment – FOREST, The product will supply to all over the world, such as: Senegal, Poland, Malta, Our company mission is that providing high quality and beautiful products with reasonable price and strive to gain 100% good reputation from our clients. We believe Profession achieves excellence! We welcome you to cooperate with us and grow up together.

The company can keep up with the changes in this industry market, product updates fast and the price is cheap, this is our second cooperation, it's good.