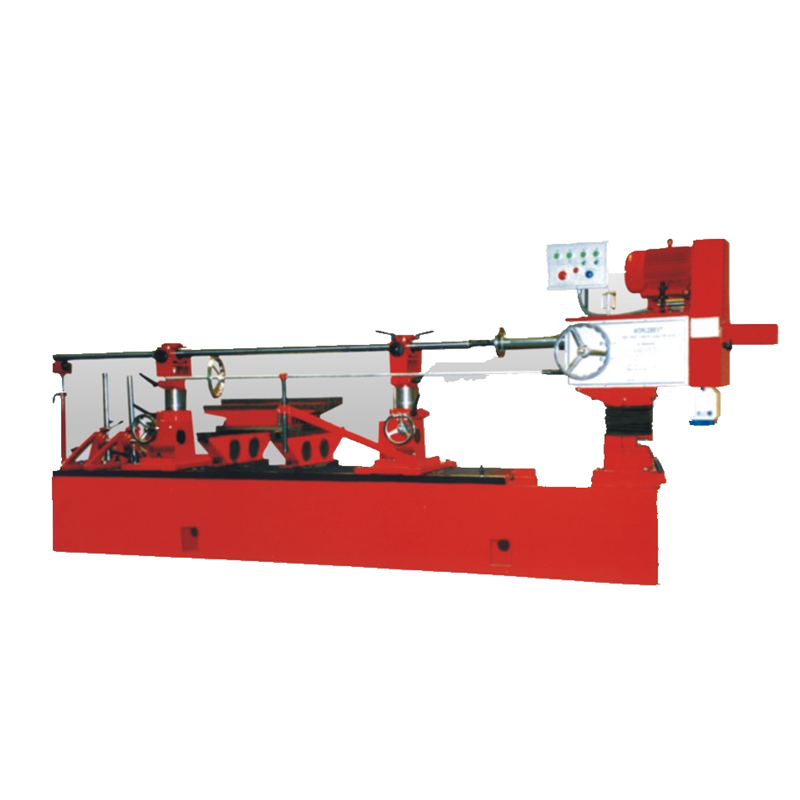

2021 New Style Slow-Feeding Nc Wire-Cut Machine - Good quality lathe turning tools for different machines – FOREST

2021 New Style Slow-Feeding Nc Wire-Cut Machine - Good quality lathe turning tools for different machines – FOREST Detail:

The cutters of lathes have steel, CBN (cubic boron nitride), Ceramic, diamond and other materials.

There are different lathe cutters for different lathing processing, we could supply the tools as your working.

How to choose a lathe tool

Choosing a lathe tool requires understanding certain factors related to the equipment. The following are very important factors that you must consider when choosing a lathe:

type of material

The type of material you cut is a fundamental factor in determining the type of lathe tool you can use. Important attributes you must pay attention to before choosing a turning tool include: hardness, wear resistance, toughness and stiffness. These properties play an important role in the types of lathe tools you can use. For example, extremely hard materials require carbide or diamond tools.

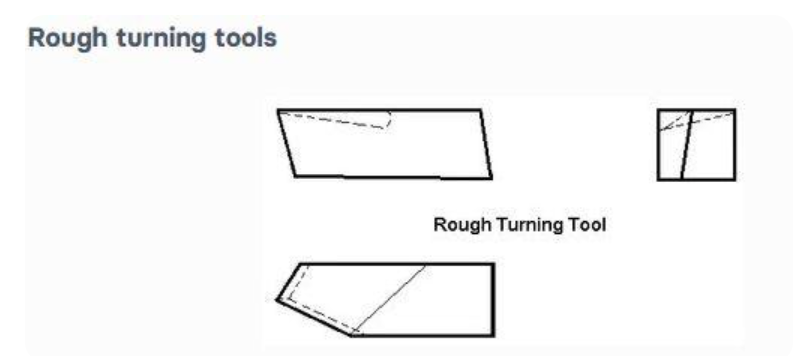

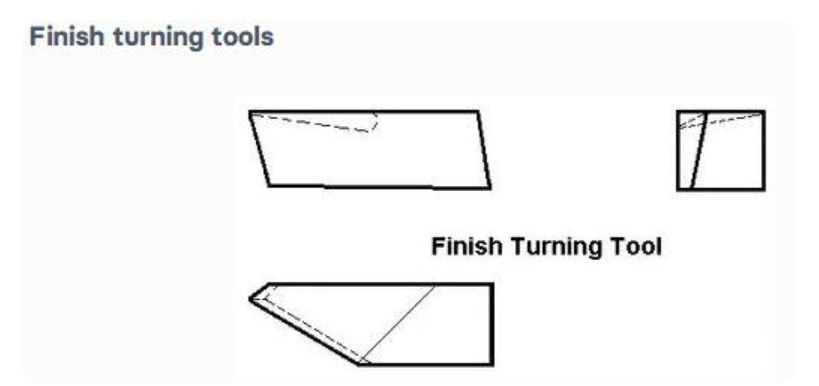

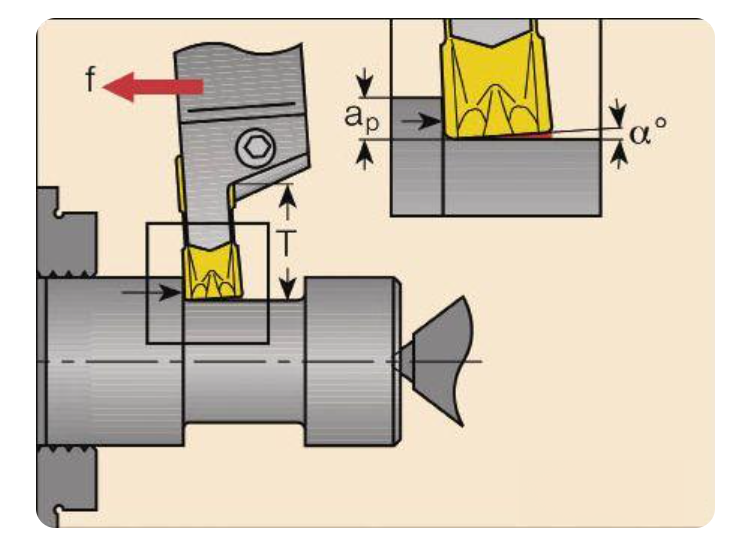

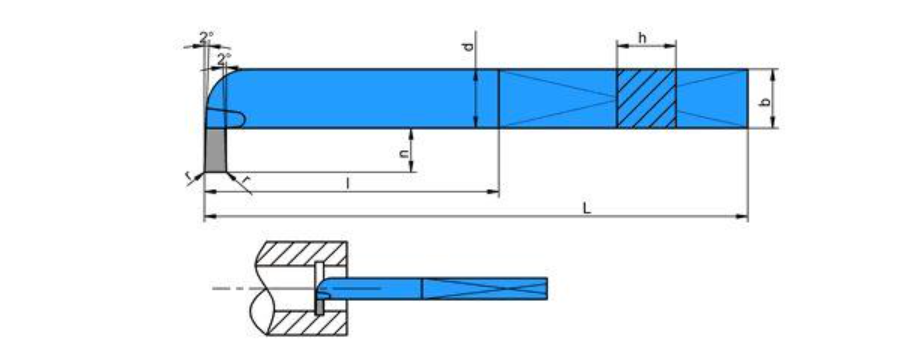

shape of tool

The shape of the lathe tool is also another factor to consider when choosing. The position of the cutting edge also determines the cutting direction of the tool (right-hand, left-hand, and round nose).

machined shape

Each type of lathe tool listed under classification can result in the specified shape. Therefore, you must integrate the desired shape into the desired turning tool. Due to the complexity of most CNC machined products, you may need to choose a combination of several lathe tools.

The type of lathe cutters:

1. Thread cutting tools

2. Chamfering tool

3. Turning tools

4. Slotting tool

5. End face cutter

6. Boring tool

7. Forming tool

8. Counter boring tool

9. Reaming tool

10. Undercutting tool

11. Drilling tools

Drilling tools are also very important tools in lathes. Drilling tools are mainly used to machine cylindrical holes in a given workpiece. In this case, the workpiece is fixed on the panel, the drill bit is fixed in the tailstock drill frame, and the hole should be completed by the movement of the tailstock spindle. This applies to regularly shaped workpieces.

B) According to the application feed method:

They are divided into three types:

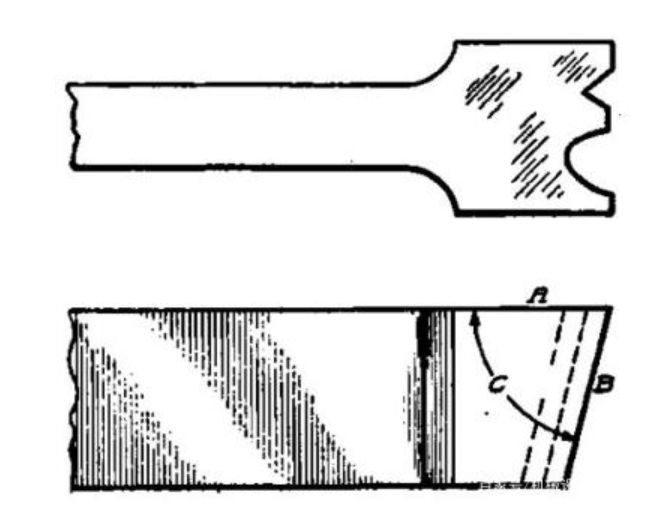

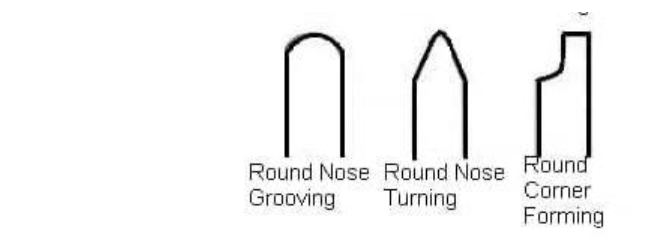

12. Round nose tool

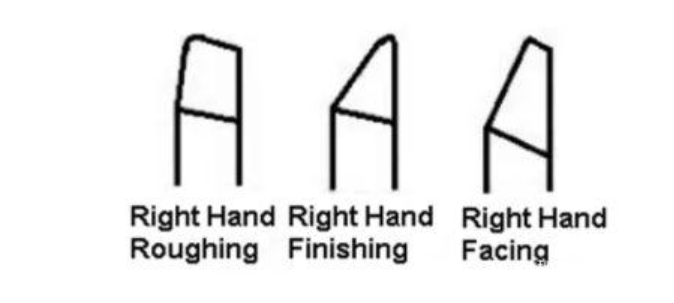

13. Right hand tool

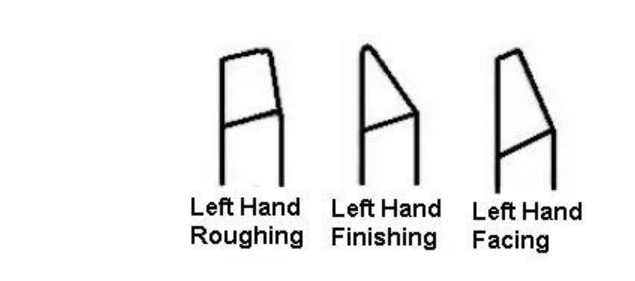

14. Left-handed tools

Unlike right-hand turning tools, left-hand tools remove material as they move from left to right (top view keeps the rake face visible). With the left hand, the thumb represents the direction of tool feed. Therefore, the main cutting edge of the tool is on the right side of the tool.

How to choose a lathe tool

Choosing a lathe tool requires understanding certain factors related to the equipment. The following are very important factors that you must consider when choosing a lathe:

type of material

The type of material you cut is a fundamental factor in determining the type of lathe tool you can use. Important attributes you must pay attention to before choosing a turning tool include: hardness, wear resistance, toughness and stiffness. These properties play an important role in the types of lathe tools you can use. For example, extremely hard materials require carbide or diamond tools.

shape of tool

The shape of the lathe tool is also another factor to consider when choosing. The position of the cutting edge also determines the cutting direction of the tool (right-hand, left-hand, and round nose).

machined shape

Each type of lathe tool listed under classification can result in the specified shape. Therefore, you must integrate the desired shape into the desired turning tool. Due to the complexity of most CNC machined products, you may need to choose a combination of several lathe tools.

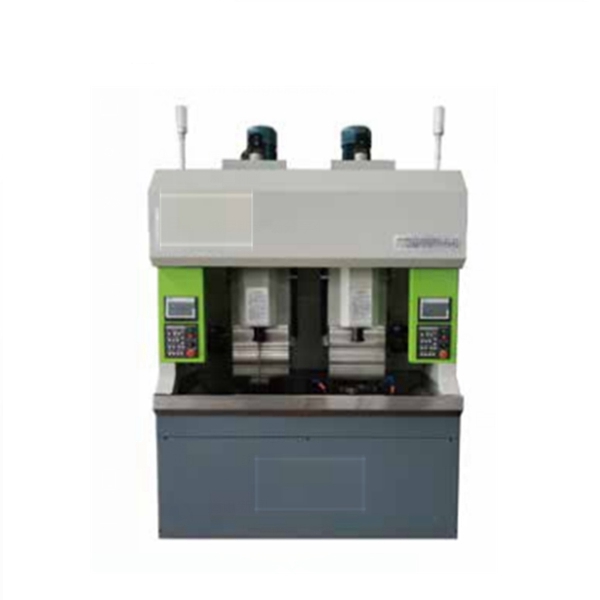

Product detail pictures:

Related Product Guide:

To be a result of ours specialty and service consciousness, our company has won a superb reputation between customers all around the environment for 2021 New Style Slow-Feeding Nc Wire-Cut Machine - Good quality lathe turning tools for different machines – FOREST, The product will supply to all over the world, such as: Florida, Kazakhstan, Luxemburg, As a way to use the resource on the expanding info in international trade, we welcome prospects from everywhere on the web and offline. In spite on the high quality objects we offer you, effective and satisfying consultation service is supplied by our qualified after-sale service group. Item lists and in depth parameters and any other info weil be sent to you timely for the inquiries. So you should make contact with us by sending us emails or call us when you've got any questions about our organization. ou could also get our address information from our site and come to our enterprise. We get a field survey of our merchandise. We're confident that we are going to share mutual accomplishment and create solid co-operation relations with our companions within this market place. We're seeking forward for your inquiries.

The factory technical staff not only have high level of technology, their English level is also very good, this is a great help to technology communication.